Preparation method of hard mutual dissolve alloy and its special device

An alloy and uniform mixing technology, applied in the field of preparation of immiscible alloys, can solve the problems of macrosegregation, recrystallization and grain growth, difficult methods, etc., achieve uniform phase distribution, small microstructure, and meet environmental protection requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

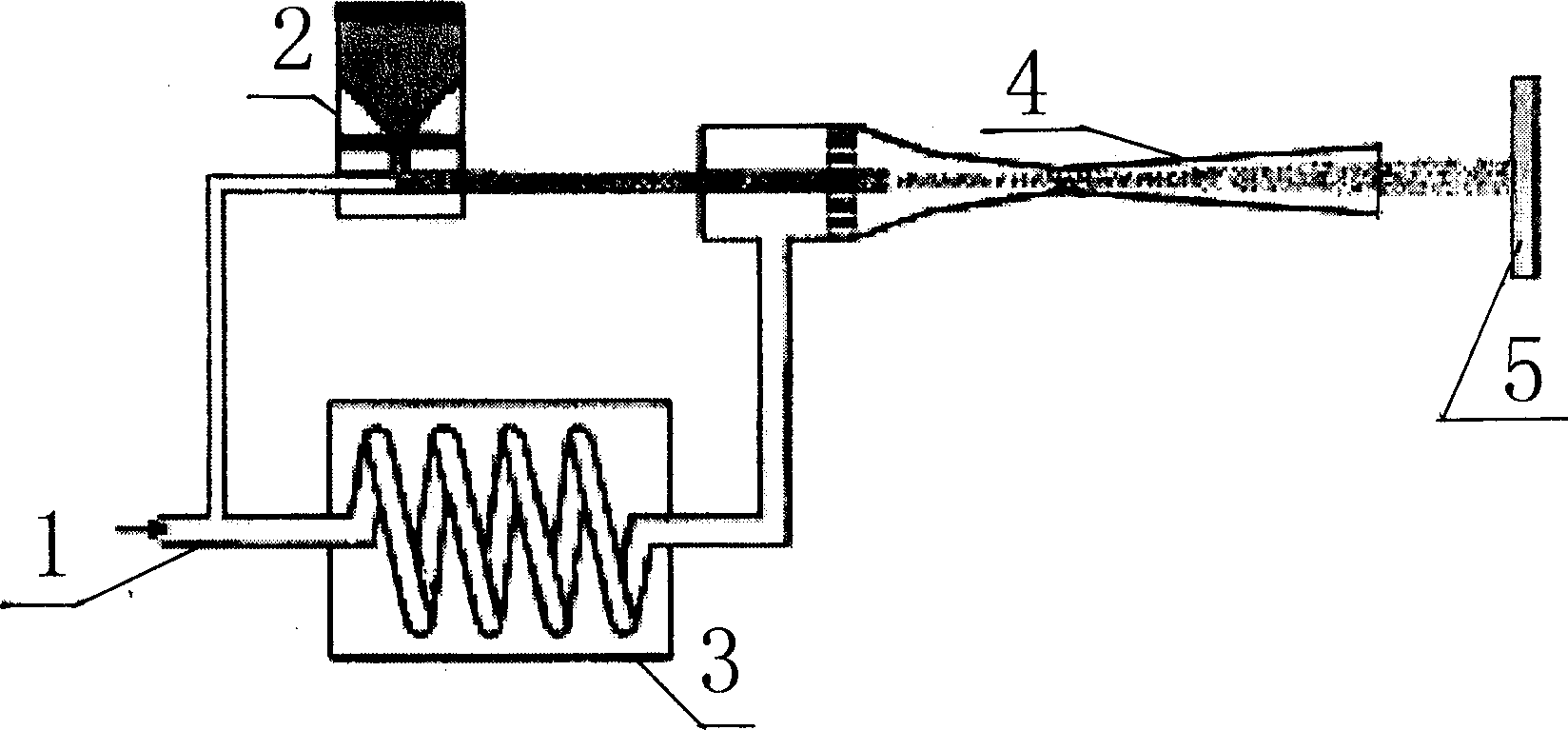

[0031] Such as figure 1 The special device for the preparation method of the immiscible alloy shown has a high-pressure gas source connected to the air inlet pipe, a heater 3, a powder feeder 2, and a supersonic nozzle 4, and the air inlet pipe 1 connected to the high-pressure air source passes through the powder feeder 2 respectively. The heater 3 is connected with the supersonic nozzle 4, the part of the inlet pipe 1 placed in the heater 3 is a spiral structure, the substrate 5 is opposite to the outlet of the supersonic nozzle, and the high-pressure gas enters the powder feeder 2 and the Heater 3, part of the gas carrying powder entering the powder feeder 2 is mixed with the preheated gas passing through the heater 3 at the entrance of the supersonic nozzle to form a gas-solid two-phase flow, and the gas-solid two-phase flow in the supersonic nozzle After the acceleration process, it reaches the supersonic state. The metal particles in the two-phase flow have high kinetic ...

Embodiment 2

[0034] The difference from Example 1 is:

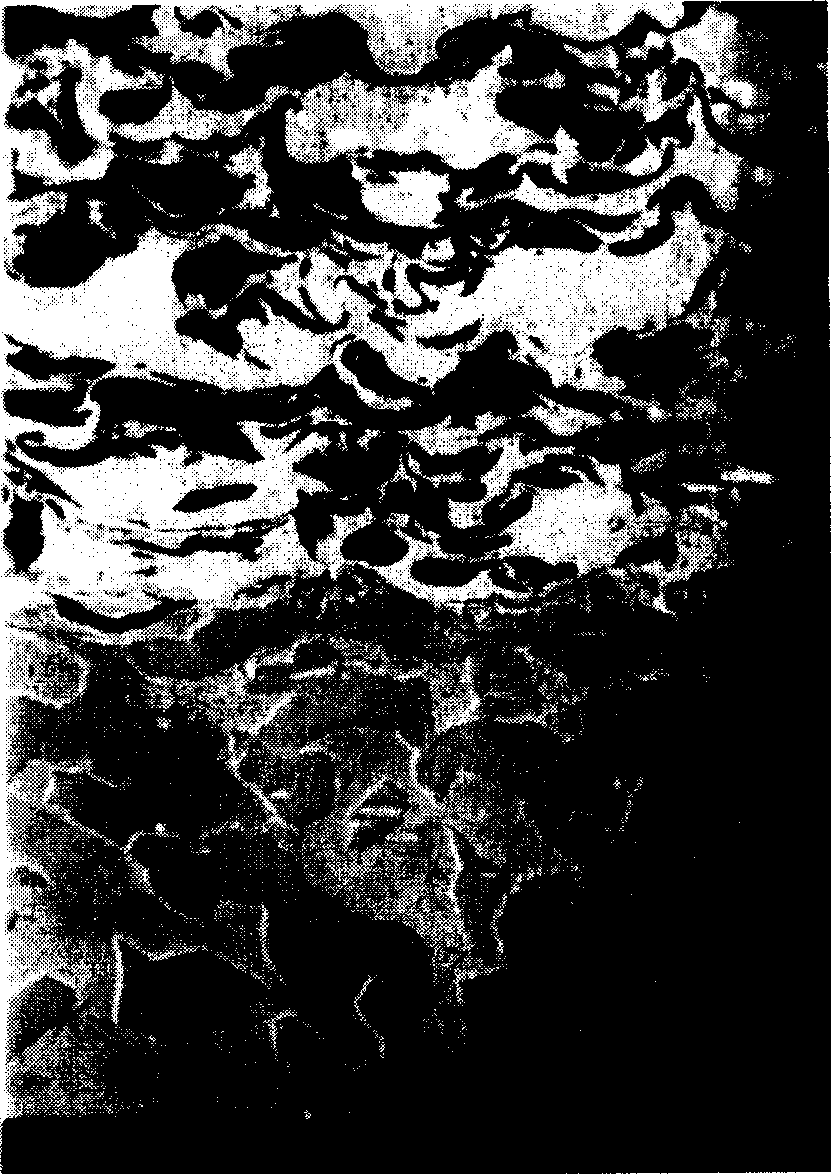

[0035] The immiscible alloy prepared in this example is an electrical material, Fe is used as a matrix, and chromium powder is used as an alloying element. The particle size is ~50 microns. As a result, an electrical material of a hard miscible alloy was obtained. The Fe and Cr phases were observed by scanning electron microscopy, and the two phases were evenly distributed and the structure was compact.

Embodiment 3

[0037] The difference from Example 1 is:

[0038]The immiscible alloy prepared in this embodiment is a high damping material Fe-Cu alloy, a mixed powder of pure iron and pure copper, and the base material is ceramics. The parameters of the spraying process are as follows: spraying distance 5mm, gas pressure 2.5MPa, gas temperature 600°C, air flow rate 30g / s, powder particle size ~ 5 microns. As a result, the Fe-Cu alloy and the coating were obtained. Observation by scanning electron microscope showed that the two phases of iron and copper were evenly distributed without obvious segregation phenomenon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com