Preparation of polymer drug-laden coating on cardiovascular stent

A drug-loaded coating and polymer technology, applied in blood vessels, stents, medical science, etc., can solve problems such as easy to fall off and affect the treatment effect, and achieve the effect of strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

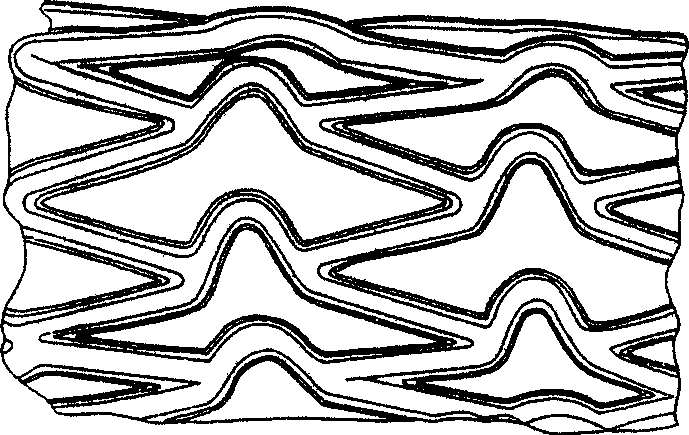

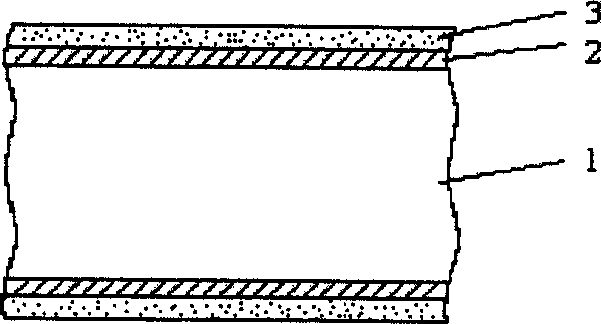

Image

Examples

Embodiment 1

[0038] The first step: the preparation of the middle layer

[0039] The surface of the 316L stainless steel stent that has undergone chemical oxidation treatment is coated with a chloroform solution of (methacryloyloxyethyl) phosphate, then dried, and then coated with a crosslinking agent, followed by photocuring treatment. Then, a cross-linking agent and a chloroform solution of aminoethylmethacrylamide are sequentially coated on it, and then photocured for use.

[0040] Step 2: Preparation of polymer drug coating

[0041] After dissolving 0.1g of poly(lactide-glycolide), wherein lactide / glycolide=80 / 20 (mol / mol), in 9.9g of chloroform, add 10mg of rapamycin and 0.1g N-(3-dimethylaminopropyl)-N'-ethylcarbodiimide was fully dissolved, and a 316L stainless steel bracket was immersed in it, and then the bracket was dried at room temperature. This coating process was repeated twice, and then the stent was vacuum desolvated at room temperature for 48 hours to obtain a polymer dr...

Embodiment 2

[0043] The first step: the preparation of the middle layer

[0044] The surface of the 316L stainless steel stent that has undergone chemical oxidation treatment is coated with a chloroform solution of (methacryloxybutyl) phosphate, then dried, and then coated with a cross-linking agent for photocuring treatment. Afterwards, a cross-linking agent and a chloroform solution of aminopropyl methacrylamide are sequentially coated thereon, and then photocured again for use.

[0045] Step 2: Preparation of polymer drug coating

[0046] After dissolving 0.2g poly(lactide-glycolide), wherein lactide / glycolide=70 / 30 (mol / mol), in 9.8g chloroform, add 40mg rapamycin and 0.2g N-(3-dimethylaminopropyl)-N'-ethylcarbodiimide was fully dissolved, and a 316L stainless steel bracket was immersed in it, and then the bracket was dried at room temperature. This coating process was repeated twice, and finally the stent was vacuum desolvated at room temperature for 48 hours to obtain a polymer dru...

Embodiment 3

[0048] The first step: the preparation of the middle layer

[0049] The surface of the 316L stainless steel stent that has undergone chemical oxidation treatment is coated with a chloroform solution of (methacryloyloxydecyl) phosphate, then dried, and then coated with a crosslinking agent for photocuring. Afterwards, a chloroform solution of a cross-linking agent and aminopentylmethacrylamide is coated sequentially thereon, and then photocured again.

[0050] Step 2: Preparation of polymer drug coating

[0051] With 0.3g poly(lactide-glycolide), wherein lactide / glycolide=50 / 50 (mol / mol), after it is dissolved in 9.7g chloroform, add 15mg rapamycin and 0.3g N-(3-dimethylaminopropyl)-N'-ethylcarbodiimide, after fully dissolving, and immerse the 316L stainless steel bracket prepared with the intermediate layer in it, take out the bracket and place it at room temperature dry. This coating process was repeated twice, and then the solvent was removed under vacuum at room temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com