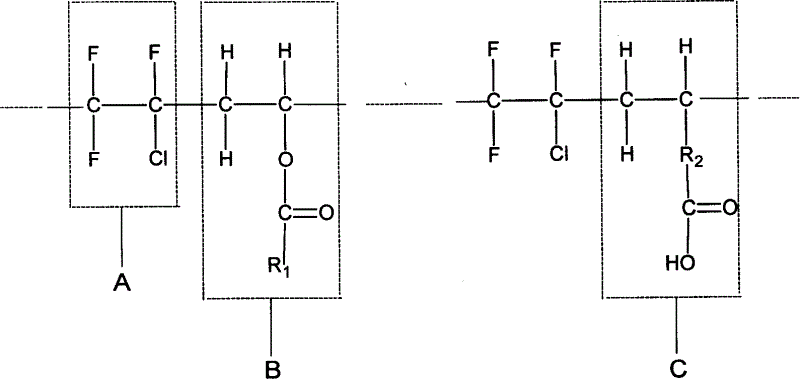

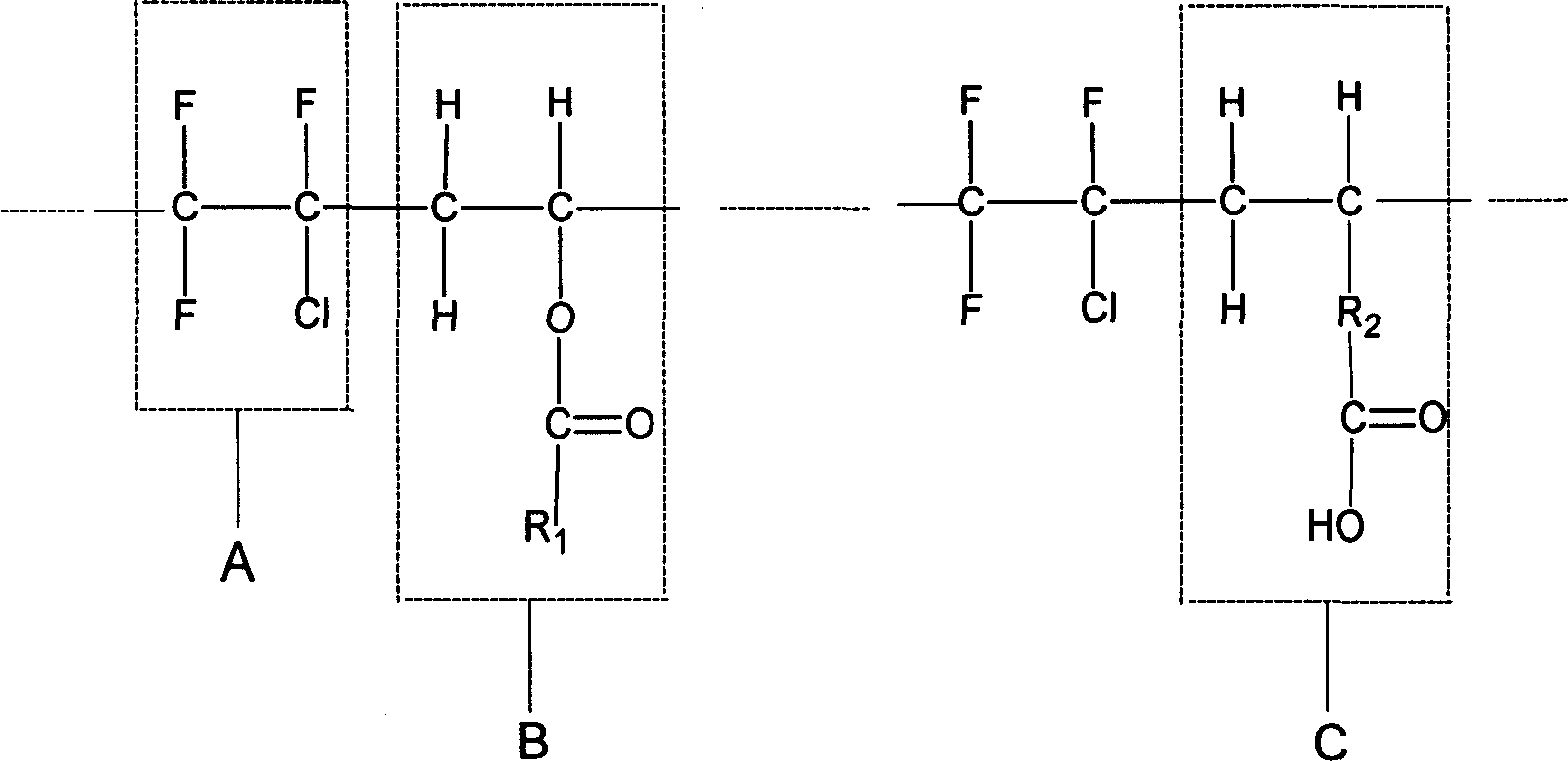

Soap-free emulsion containing polytrifluorochloroethylene and its prepn

A soap-free emulsion and chlorotrifluoroethylene technology, applied in the field of ternary fluoropolymer emulsion and its preparation, can solve the problems of difficult adsorption, harsh polymerization conditions, expensive fluorocarbon surfactants, etc., and achieve environmental pollution. Small and stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

[0022] 600g of deionized water, 112g of vinyl acetate, 18g of heptenoic acid, 12g of sodium hydroxide and 1.9g of potassium persulfate were added to a 1.5L high-pressure reactor with electromagnetic stirring. After three times of replacement with nitrogen gas, replacement with chlorotrifluoroethylene, and vacuum pumping, connect the feed valve of the reactor to the storage tank of chlorotrifluoroethylene, add 300 g of chlorotrifluoroethylene to the reactor, close the valve to raise the temperature, and stir , when the temperature in the kettle reaches 70±2°C, add 38g of vinyl acetate, 9g of heptenoic acid, and 70g of chlorotrifluoroethylene into the reaction kettle continuously from the liquid metering tank through the injection pump, and the pressure after the feeding is about 1.8Mpa, After 24 hours, when the reaction pressure in the kettle was about 1.1 MPa, the reaction was terminated, and the material was cooled and discharged. The mixture obtained by the above reaction is...

example 3

[0025] Fluorine content of polymer in emulsion (%)

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com