Light-diffusing sheet, optical device, and image display

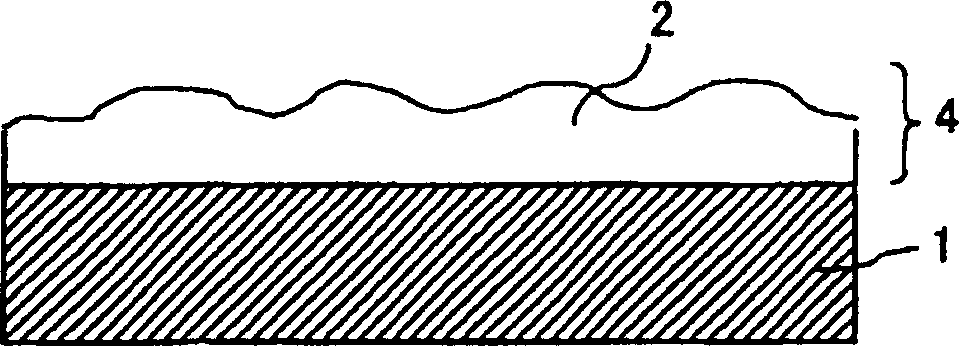

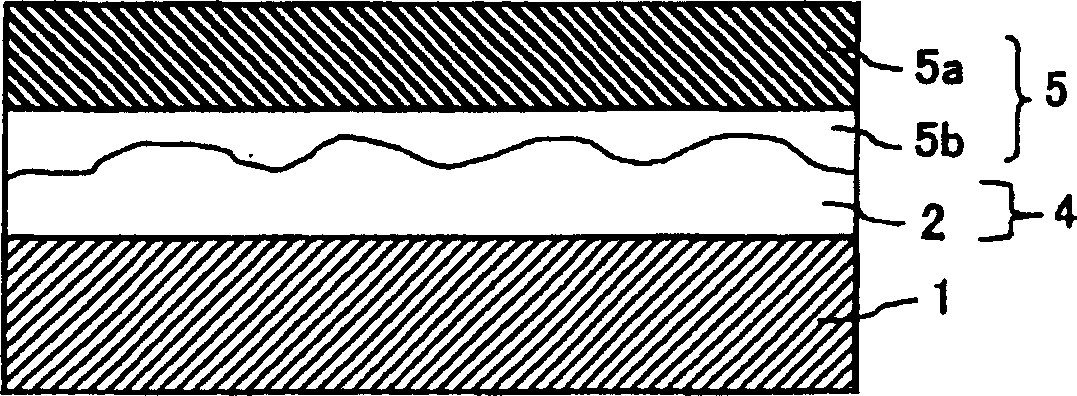

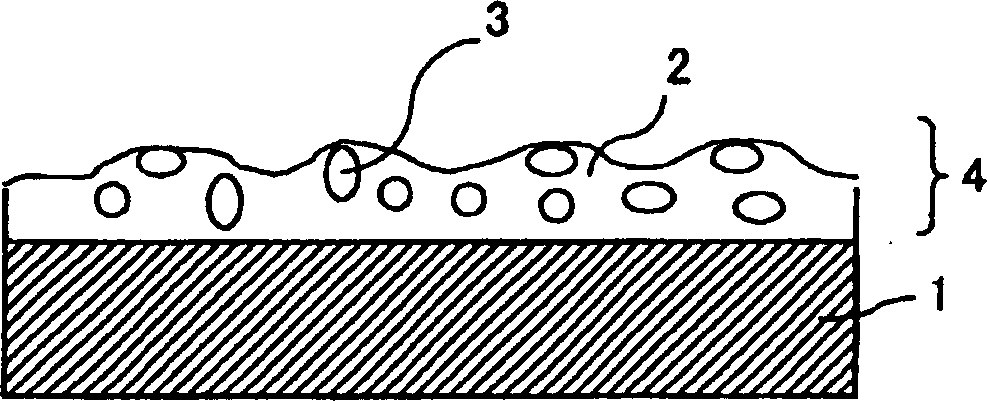

一种光扩散片、浊度的技术,应用在光学元件、光学、漫射元件等方向,能够解决树脂被膜层剥落、难以形成光扩散层、变质等问题,达到平衡性良好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0112] 75 parts by weight of an alternating copolymer (the content of N-methylmaleic anhydride imide is 50 mol%) made of isobutylene and N-methylmaleic anhydride imide, and the content of acrylonitrile is 28 parts by weight 25 parts by weight of the acrylonitrile-styrene copolymer was dissolved in methylene chloride to obtain a solution having a solid content concentration of 15% by weight. This solution was cast on a polyethylene terephthalate film, applied in the form of a glass plate, and after standing at room temperature for 60 minutes, it was peeled off from the film. After drying at 100° C. for 10 minutes, drying at 140° C. for 10 minutes, and then drying at 160° C. for 30 minutes gave a transparent film with a thickness of 50 μm. The in-plane phase difference of the transparent film was Re=4 nm, and the thickness direction phase difference Rth=4 nm.

[0113] In addition, the in-plane retardation Re and the thickness direction retardation Rth are the measurement result...

manufacture example 2

[0115] A glutarimide copolymer consisting of N-methylglutarimide and methyl methacrylate (N-methylglutarimide content 75% by weight, acid content 0.01 meq / g Hereinafter, 65 parts by weight of acrylonitrile-styrene copolymer having a glass transition temperature of 147°C) and 35 parts by weight of an acrylonitrile-styrene copolymer whose contents of acrylonitrile and styrene are 28% by weight and 72% by weight, respectively, were melt-kneaded to obtain a resin composition The material was supplied to a T-die melt extruder to obtain a film with a thickness of 135 μm. After the film was stretched 1.7 times in the MD direction at 160°C, it was stretched 1.8 times in the TD direction at 160°C. The obtained biaxially stretched transparent film had a thickness of 55 μm, an in-plane retardation Re=1 nm, and a thickness direction retardation Rth=3 nm.

Embodiment 1

[0117] With respect to 100 parts of acrylic urethane-based ultraviolet curable resin (urethane acrylate monomer), 12 parts of polystyrene particles with an average particle diameter of 3.5 μm, benzophenone-based photo 5 parts of polymerization initiator, 2.5 parts of thixotropic agent (mica) form the coating liquid that solid content concentration is 40% by weight, and above-mentioned coating liquid is coated on the transparent film that obtains by Manufacturing Example 1, at 120 ℃ After drying for 5 minutes, it was cured by irradiating ultraviolet rays to prepare a light-diffusing sheet having a resin film layer on a surface with a fine uneven structure with a coating film thickness of 7 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| turbidity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com