Method for preparing hole structure gradient changing spherical inner hole artificial bone

A technique of gradient change and pore structure, applied in bone implants and other directions, can solve the problems of poor pore connectivity and insufficient scaffold strength, and achieve the effects of good connectivity, good mechanical properties and biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

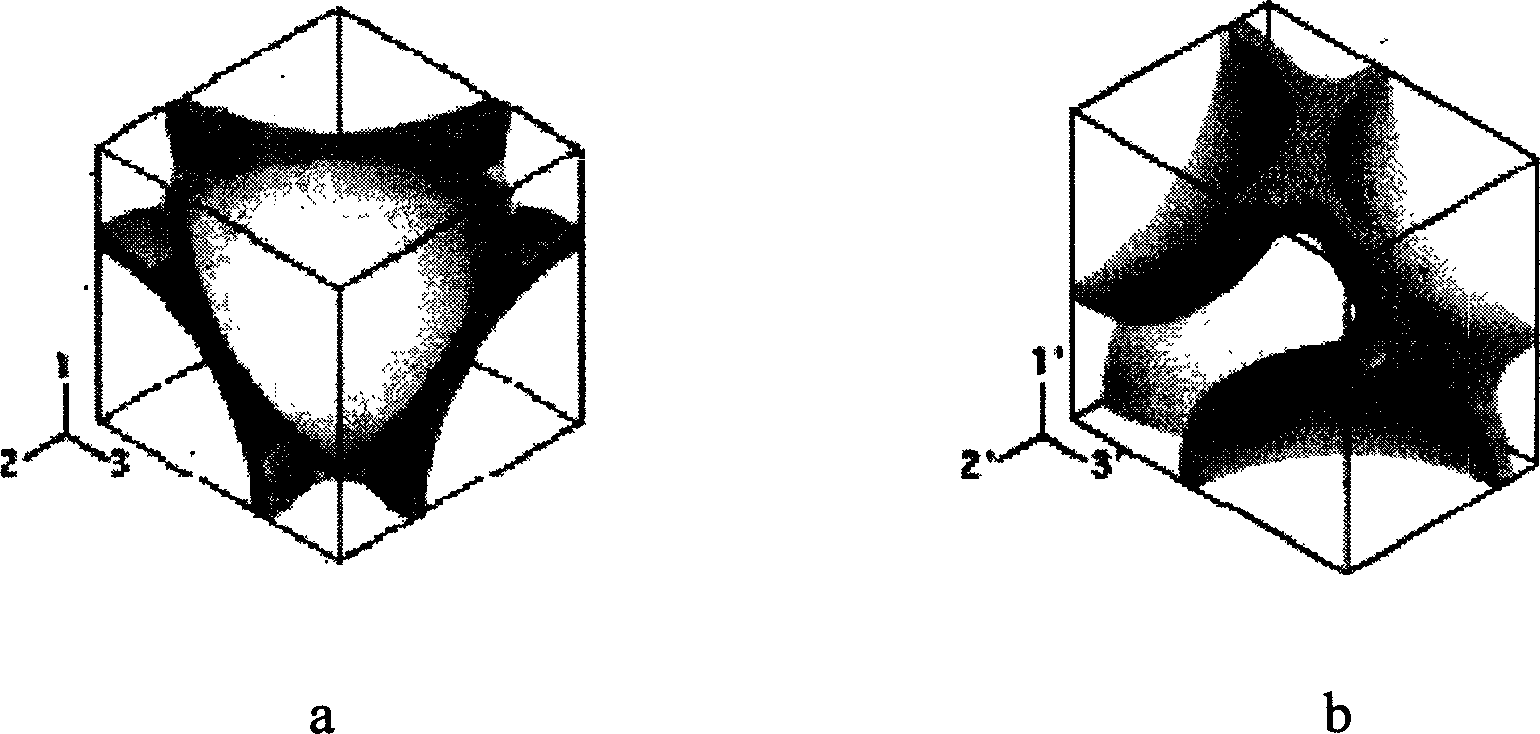

[0036] The preparation method of the artificial bone with the spherical inner hole in which the pore structure is gradiently changed comprises the following steps:

[0037] The first step, preparation of binder and slurry

[0038] Dissolve 0.5-1.0g of PS plastic into 10-100ml of carbon tetrachloride, stir to dissolve completely, and let stand until clarified to obtain a binder;

[0039] Add 10-200ml of absolute ethanol to 10-50g of hydroxyapatite powder with a particle size of 0.1-5μm, and then add 0.2-3ml of polyvinyl butyral. The volume ratio of the powder and the mixture of absolute ethanol is 1%, and the mixture is evenly stirred to obtain a hydroxyapatite slurry;

[0040] The second step, the preparation of polymer spheroid scaffold

[0041] Take polyvinyl chloride spheres with a particle size of 50-1000 μm and salt crystals with a particle size of 20-600 μm, and mix them at a volume ratio of 2-5:1. 0.6 times, placed in a plastic mold, the arrangement of the polyvinyl ...

Embodiment 1

[0049] The preparation method of the artificial bone with the spherical inner hole in which the pore structure is gradiently changed comprises the following steps:

[0050] The first step, preparation of binder and slurry

[0051] Dissolve 0.5g of PS plastic into 30ml of carbon tetrachloride, stir to dissolve completely, and let stand until clarification to obtain a binder;

[0052] Add 10ml of absolute ethanol to 20g of hydroxyapatite powder with a particle size of 0.1-5μm, and then add 0.2ml of polyvinyl butyral. The volume ratio of the mixture is 1%, and the mixture is evenly stirred to obtain a hydroxyapatite slurry;

[0053] The second step, the preparation of polymer spheroid scaffold

[0054] Take polyvinyl chloride spheres with a particle size of 50-380 μm and salt crystals with a particle size of 20-230 μm, mix them in a volume ratio of 2:1, and place them in a plastic mold. The arrangement of the polyvinyl chloride spheres in the mold is: The size of the balls gra...

Embodiment 2

[0060] The preparation method of the artificial bone with the spherical inner hole in which the pore structure is gradiently changed comprises the following steps:

[0061] The first step, preparation of binder and slurry

[0062] Dissolve 0.6g of PS plastic into 40ml of carbon tetrachloride, stir to dissolve completely, and let it stand until clarified to obtain a binder;

[0063] Add 200ml of absolute ethanol to 30g of hydroxyapatite powder with a particle size of 0.1-5μm, and then add 3ml of polyvinyl butyral, which will occupy the mixture of hydroxyapatite powder and absolute ethanol The volume ratio of the mixture is 1%, and the mixture is evenly stirred to obtain a hydroxyapatite slurry;

[0064] The second step, the preparation of polymer spheroid scaffold

[0065] Take polyvinyl chloride spheres with a particle size of 150-550 μm and salt crystals with a particle size of 60-325 μm, mix them in a volume ratio of 3:1, and place them in a plastic mold. The arrangement o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com