Zineb synthesizing process

A new technology of zinc generation, applied in the field of pesticides, can solve the problems of decreased content, falsely high content, frequent claims, etc., and achieves the effect of a simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

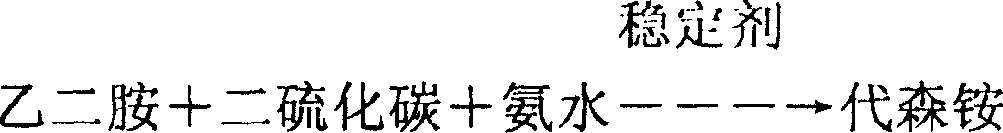

[0015] 1, the synthesis of dysonium

[0016]

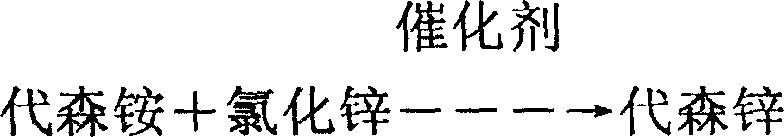

[0017] 2. Synthesis of Zinc

[0018]

[0019] Wherein, when synthesizing Zineb, the consumption of ethylenediamine, carbon disulfide, 40% ammonia water is respectively: 180Kg, 491Kg, 540Kg or by similar ratio; The dosage is respectively: 1200Kg, 225Kg or according to the similar ratio. Add stabilizer (addition amount can be according to routine) in the process of synthesizing ammonium. The added stabilizer is sodium metabisulfite (or sodium sulfite, hydrosulfite, etc.), or other suitable stabilizers. The catalyst is added in the process of synthesizing Zinc (the addition amount is in accordance with the general similar synthesis reaction). The added catalyst is Bi 2 (MoO 4 ) 3 (or Ni / Al 2 o 3 、Pol 6 (CO) X etc.), or other suitable catalysts.

[0020] In the present invention, ammonia water is used instead of caustic soda to control the synthetic pH value to produce ammonium when synthesizing sodium ammoniu...

Embodiment 2

[0022] 1, the synthesis of dysonium

[0023]

[0024] 2. Synthesis of Zinc

[0025]

[0026] Wherein, when synthesizing Zineb, the consumption of ethylenediamine, carbon disulfide, 40% ammonia water is respectively: 150Kg, 441Kg, 500Kg or by the same ratio; The dosage is respectively: 1000Kg, 200Kg or according to the same ratio. Add stabilizer (addition amount can be according to routine) in the process of synthesizing ammonium. The added stabilizer is sodium sulfite (or other stabilizers with similar effect). The catalyst is added in the process of synthesizing Zinc (the addition amount can be according to the routine). Added catalyst is Ni / Al 2 o 3 (or other catalysts with a similar effect).

Embodiment 3

[0028] 1, the synthesis of dysonium

[0029]

[0030] 2. Synthesis of Zinc

[0031]

[0032] Wherein, when synthesizing Zineb, the consumption of ethylenediamine, carbon disulfide, 40% ammonia water is respectively: 210Kg, 541Kg, 590Kg or by the same ratio; The dosage is respectively: 1400Kg, 250Kg or according to the same ratio. Add stabilizer (addition amount can be according to routine) in the process of synthesizing ammonium. The added stabilizer is hydrosulfite (or other stabilizers with similar effects). The catalyst is added in the process of synthesizing Zinc (the addition amount can be according to the routine). The added catalyst is or Pol 6 (CO) x (or other catalysts with a similar effect).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com