Multifunctional ablation-resistant adhesive for thermal protection and method for preparing same

A thermal protection and ablation-resistant technology, applied in the direction of adhesives, etc., can solve the problems of complex construction process and achieve the effect of low line ablation rate, good adhesion and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

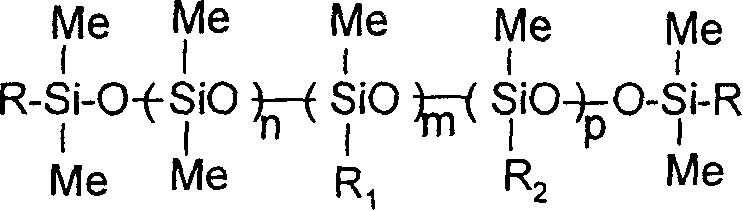

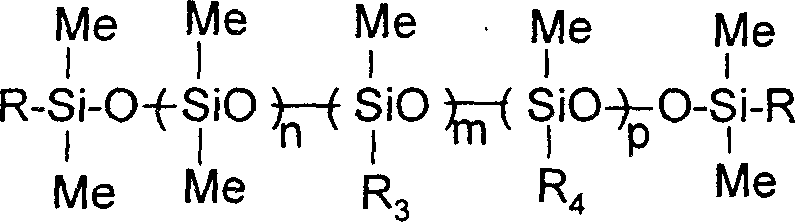

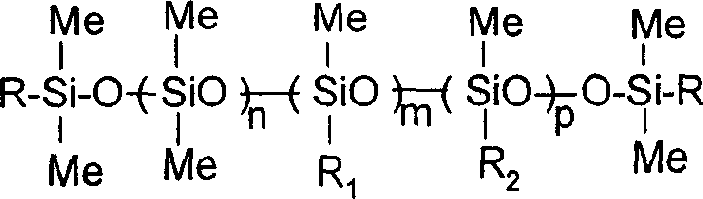

Method used

Image

Examples

Embodiment 1

[0054] The raw material components of the ablation-resistant adhesive for multifunctional thermal protection of the present invention are as follows, all in parts by weight:

[0055] Polysiloxane I 50

[0056] Polysiloxane II 50

[0057] 105 resin 5

[0058] Silica 15

[0059] Toner 8

[0062] γ-Glycidoxypropyltrimethoxysilane 1

[0063] Hexamethyldisilazane 1.5

[0064] Orthoethyl silicate 2

[0065] Stannous octoate 1.4

[0066] Refer to the literature (Feng Shengyu, Zhang Jie, Li Meijiang, Zhu Qing addendum, organosilicon polymer and its application, Chemical Industry Press, 2004, Chapter 3) to introduce the method to prepare polysiloxane I or II. For example: Add octamethylcyclotetrasiloxane, various modified cyclosiloxanes, catalysts, etc. in proportion 2 In the reaction flask of conduit and reflux device, under N 2 Under protection, slowly heat to 80-90° C., stir and keep warm for 1-2 hours, then add end-cappi...

Embodiment 2

[0073] The raw material components are as follows, all in parts by weight:

[0074] Polysiloxane I 40

[0075] Polysiloxane II 60

[0076] 105 resin 4.5

[0077] Silica 20

[0078] Toner 8

[0080] Zinc oxide 3

[0081] γ-Glycidoxypropyltrimethoxysilane 1

[0082] Hexamethyldisilazane 1.5

[0083] Orthoethyl silicate 2

[0084] Stannous octoate 1.4

[0085] Referring to the preparation method of Example 1, the ablation-resistant adhesive for multifunctional thermal protection was obtained. Its properties are: ablation rate 0.170mm / s; tensile strength 3.59MPa; density 1.19g / cm 3 ; Bonding and peeling strength of steel is 3.46MPa.

Embodiment 3

[0087] The raw material components are as follows, all in parts by weight:

[0088] Polysiloxane I 45

[0089] Polysiloxane II 55

[0090] 105 resin 4.3

[0091] Silica 18

[0092] Toner 10

[0094] Zinc oxide 3

[0095] γ-Glycidoxypropyltrimethoxysilane 1

[0096] Hexamethyldisilazane 1.5

[0097] Orthoethyl silicate 2

[0098] Stannous octoate 1.4

[0099]Referring to the preparation method of Example 1, the ablation-resistant adhesive for multifunctional thermal protection was obtained. Its properties are: ablation rate 0.176mm / s; tensile strength 3.45MPa; density 1.18g / cm 3 ; Bonding and peeling strength of steel is 3.25MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com