Three-dimensional ordered micron porous polymer membrane and its preparing method

A polymer membrane, three-dimensional ordered technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of inability to achieve dynamic control, cumbersome preparation process, low yield, etc., and achieve a simple and easy preparation method. The effect of simple operation, simple preparation method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

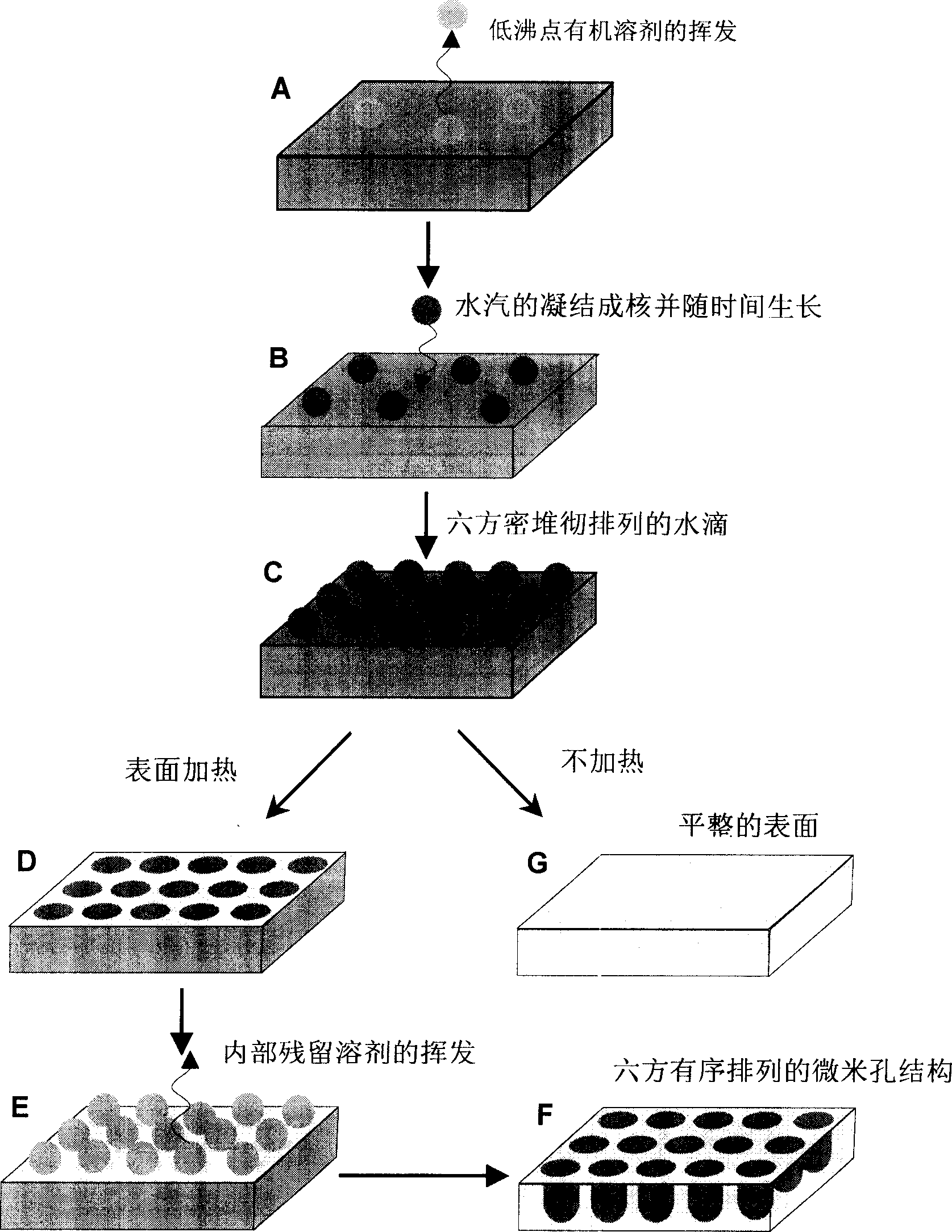

Method used

Image

Examples

Embodiment 1

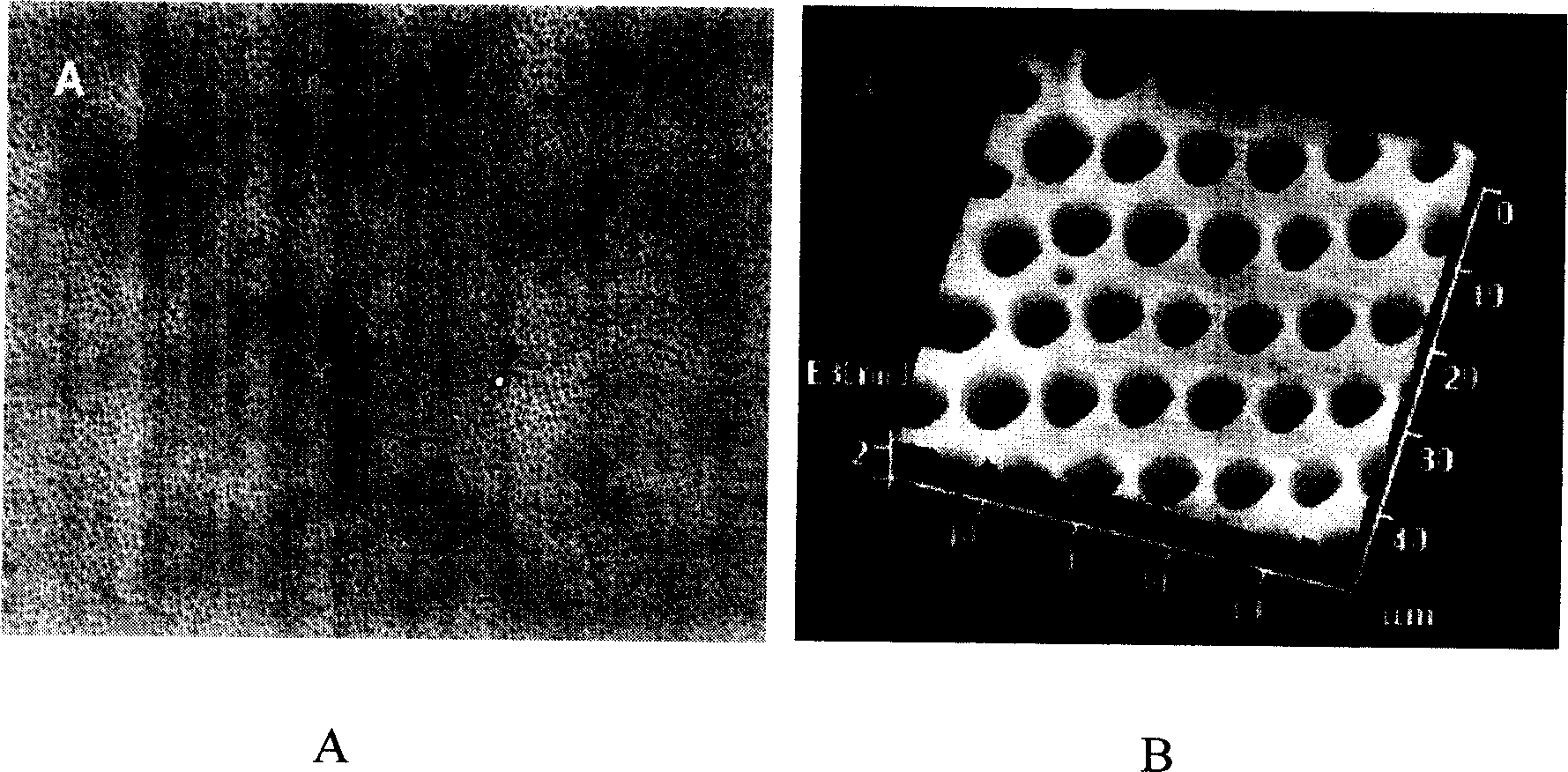

[0037] Polystyrene (PS) was dissolved in the volatile organic solvent chloroform (CHCl 3 ) to prepare a dilute polymer solution with a concentration of 1% by weight, then deposit a certain amount of the dilute solution on the plane of a smooth glass substrate, volatilize freely at room temperature in the atmosphere for 0.5 minutes, turn on the radiation source and heat for about 5 A three-dimensional ordered microporous polymer membrane with a pore diameter of 2.1 μm is obtained within minutes. like figure 2 shown.

Embodiment 2

[0039] Dissolve polystyrene (PS) in volatile organic solvent carbon disulfide (CS2 ) to prepare a dilute polymer solution with a concentration of 1% by weight, and then deposit a certain amount of the dilute solution on the flat surface of a smooth silicon wafer substrate, volatilize freely at room temperature in the atmosphere for 1 minute, turn on the irradiating light source and heat for about In 3 minutes, a three-dimensional ordered microporous polymer membrane with a pore diameter of 2.5 μm is obtained.

Embodiment 3

[0041] Polystyrene (PS) was dissolved in the volatile organic solvent chloroform (CHCl 3 ) to prepare a dilute polymer solution with a concentration of 2% by weight, and then deposit a certain amount of the dilute solution on the plane of a smooth aluminum sheet substrate, volatilize freely at room temperature in the atmosphere for 1.5 minutes, turn on the radiation source and heat for about Within 3 minutes, a three-dimensional ordered microporous polymer membrane with a pore diameter of 3.5 μm was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com