Method of manufacturing nickel powder, apparatus for manufacturing nickel powder, and crucible for manufacturing nickel powder

A manufacturing method and a manufacturing device technology, which are applied in the field of crucibles for nickel powder manufacturing, and can solve the problems of affecting the characteristics of capacitors and affecting the composition of electronic device materials such as capacitors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

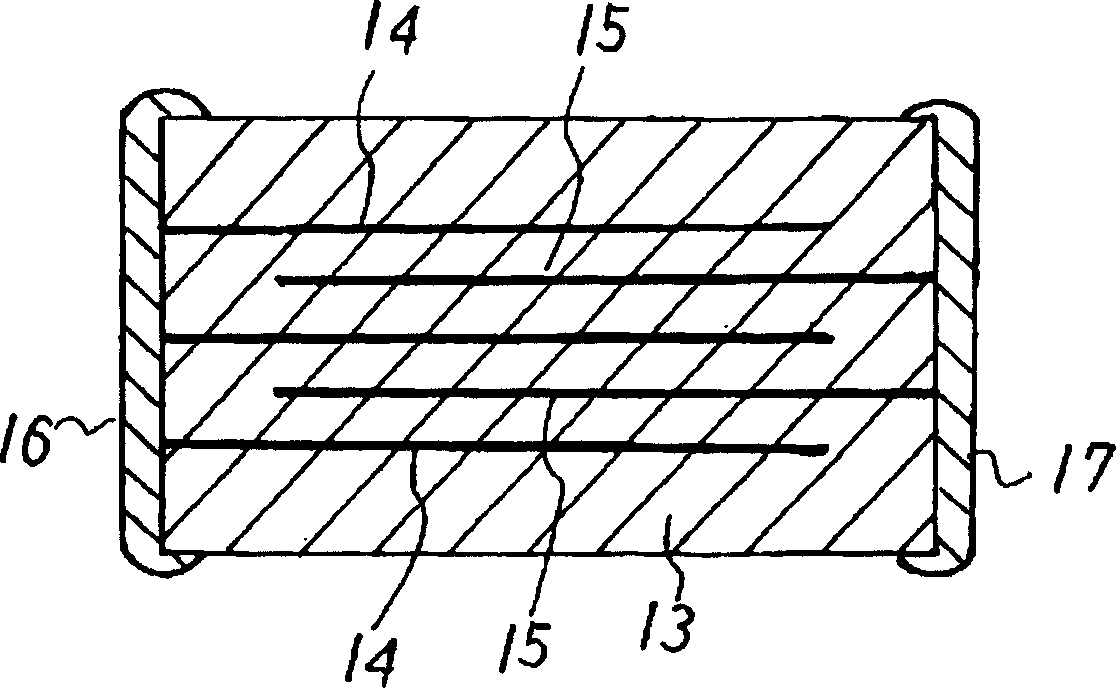

[0049] A capacitor of JIS standard C1608JB1A105K was trial-produced, that is, a capacitor with a capacity of 10 μF was obtained with a size of 1.6mm×0.8mm×0.8mm. figure 2 The illustrated internal electrodes 14 , 15 and terminal electrodes 16 , 17 use nickel powder as the base layer, and the dielectric layer 13 uses a barium titanate-based substance as described below. That is, the composition is BaTiO 3 : 95.47 mol%, Y 2 o 3 : 0.57 mol%, MgO: 1.91 mol%, V 2 o 5 : 0.002 mol%, {Ba 0.58 Ca 0.42}SiO 3 : 1.91 mol%, MnO: 0.14 mol% ceramics.

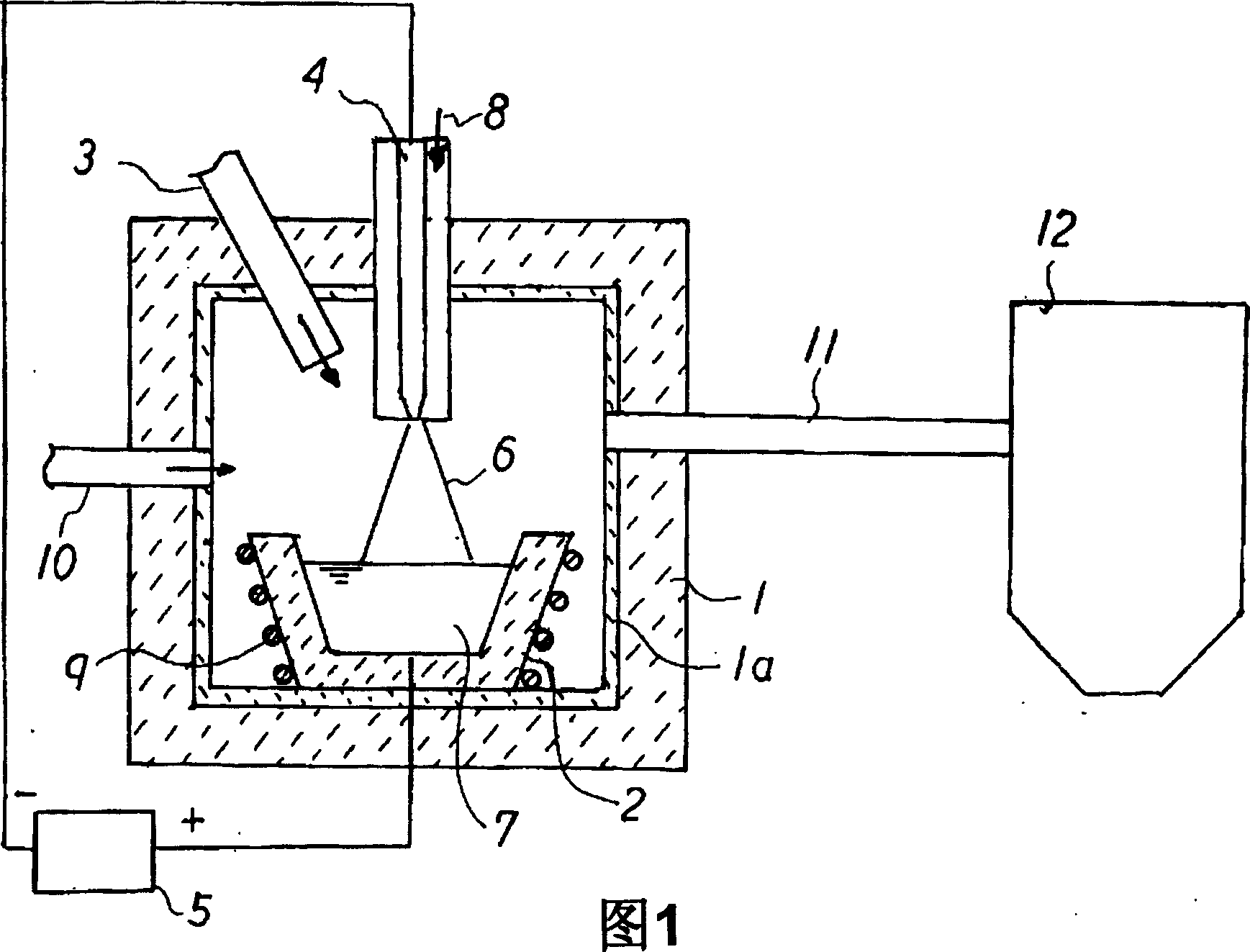

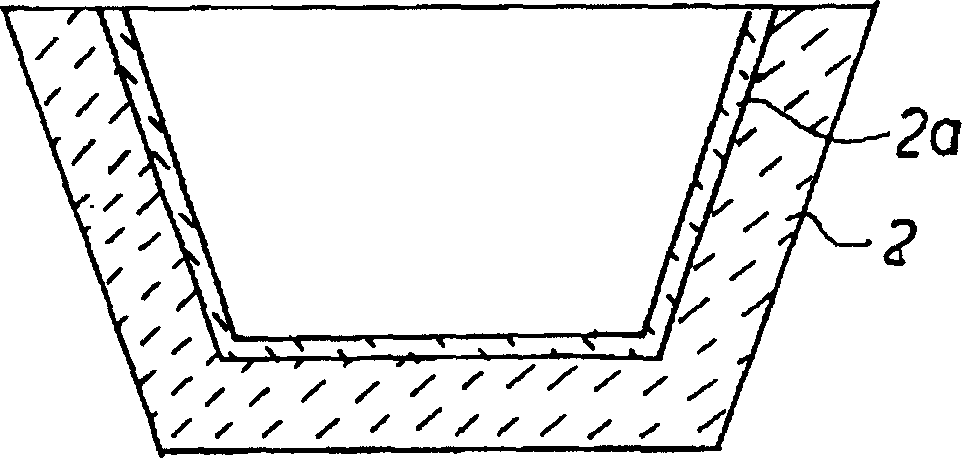

[0050] On the other hand, as the crucible, SiO 2 -Al 2 o 3 -FeO-P 2 o 5 - Substances of the C series. Then, if Figure 4 As shown, the entire surface of the crucible 2 is covered by coating and thermobonding with the substance of the composition used in the above-mentioned dielectric layer 13 . The inner wall 1 a of the reaction furnace 1 is also covered with the same material as the above-mentioned dielectric layer 13 .

[0051...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com