Preparation method of grain size controllable single dispersed nano silver powder

A nano-silver powder and monodisperse technology, which is applied in the field of preparation of monodisperse nano-silver powder, can solve the problems of small silver sol particle size, low silver concentration, and preparation of nano-silver powder, and achieve narrow particle size distribution, high purity, and good dispersion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

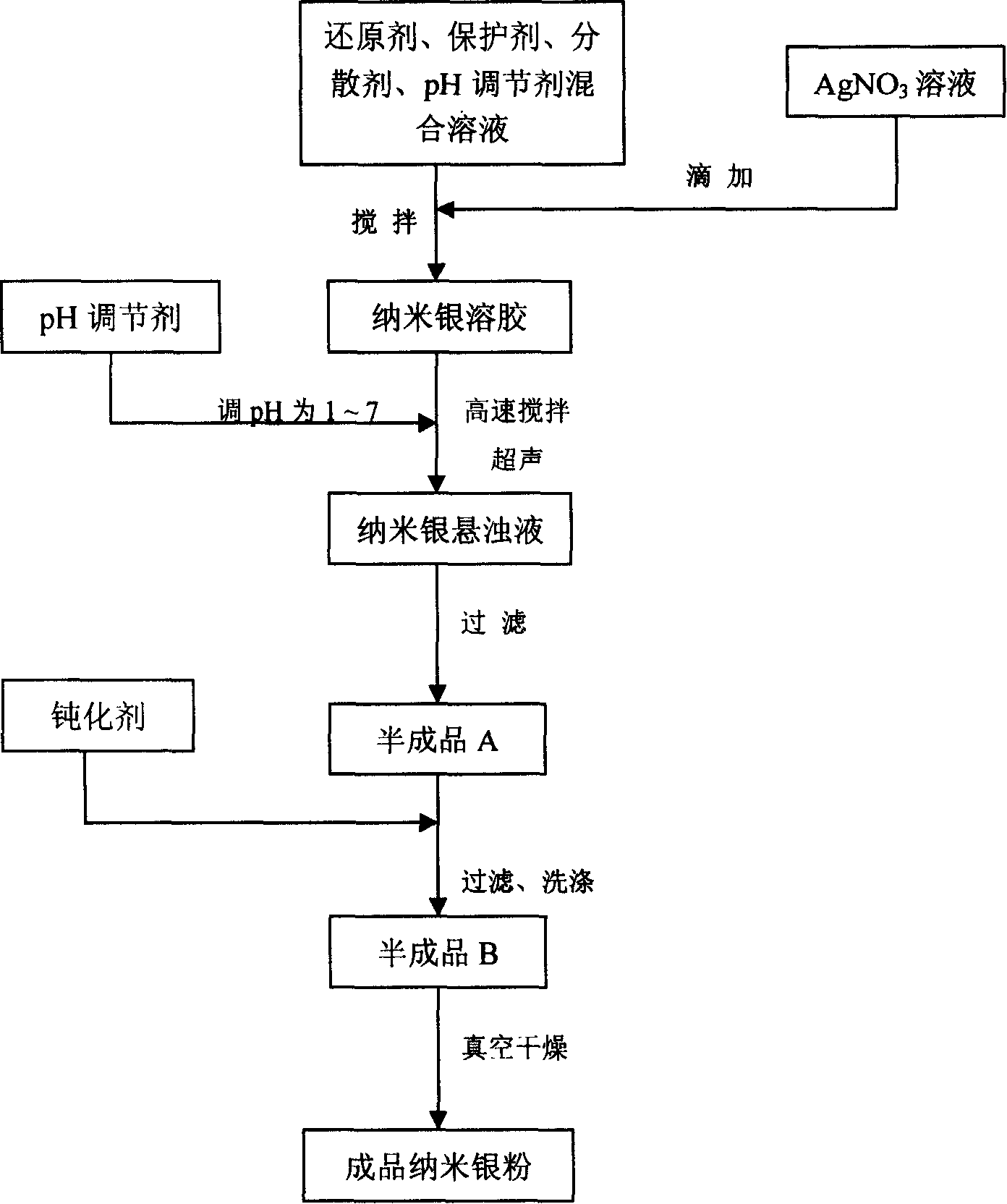

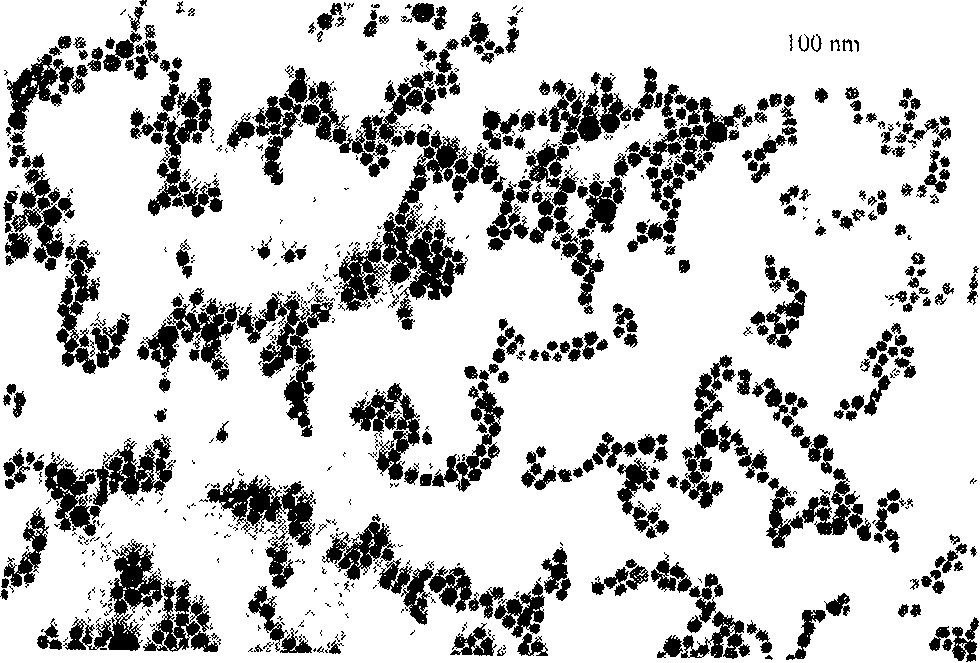

[0029] Embodiment 1: as attached figure 1 , 2 , 7, prepare silver nitrate solution: take 34g silver nitrate, dissolve with 200mL deionized water; the preparation of reducing solution: sodium hypophosphite (NaH 2 PO 2 ·H 2 O) 14g, PVP 34g, sodium hexametaphosphate 4.3g, 10% H 2 SO 4 25mL, deionized water 1200mL; put the reducing solution in a stirred 3000mL three-necked bottle, and heat it in a water bath at 40°C; add the silver nitrate solution dropwise at 20 drops / min at a speed of 300r / min, after the dropwise addition is completed, Stirring was continued for 60 minutes; a silver sol was obtained. Place the prepared silver sol together with the three-necked bottle in an ultrasonic vessel, ultrasonically at 300W, while stirring at a speed of 1000r / min, add dropwise an ammonia solution with a mass fraction of 10% until the pH of the sol is 2; Set aside for 15 minutes, filter with 5 layers of slow-speed quantitative filter paper, soak the filter paper with ammonia water wi...

Embodiment 2

[0030] Embodiment 2: as attached figure 1 , 3 , 7, prepare silver nitrate solution: take 17g silver nitrate, dissolve with 200mL deionized water; the preparation of reducing solution: sodium hypophosphite (NaH 2 PO 2 ·H 2 O) 7g, PVP 15g, sodium hexametaphosphate 2.5g, 10% H 2 SO 4 10mL, deionized water 500mL; put the reducing solution in a stirred 1000mL three-necked flask, and heat it in a water bath at 50°C; add silver nitrate solution dropwise at 20 drops / min at a speed of 500r / min; silver sol is prepared. Place the prepared silver sol together with the three-necked bottle in an ultrasonic container, ultrasonically at 400W, while stirring at a speed of 600r / min, add dropwise an ammonia solution with a mass fraction of 2% until the pH of the solution is 3; Set aside for 15 minutes, filter with 4 layers of slow-speed quantitative filter paper, soak the filter paper with ammonia water with a mass fraction of 5%; passivate with a 1,2,3-benzotriazole solution with a mass f...

Embodiment 3

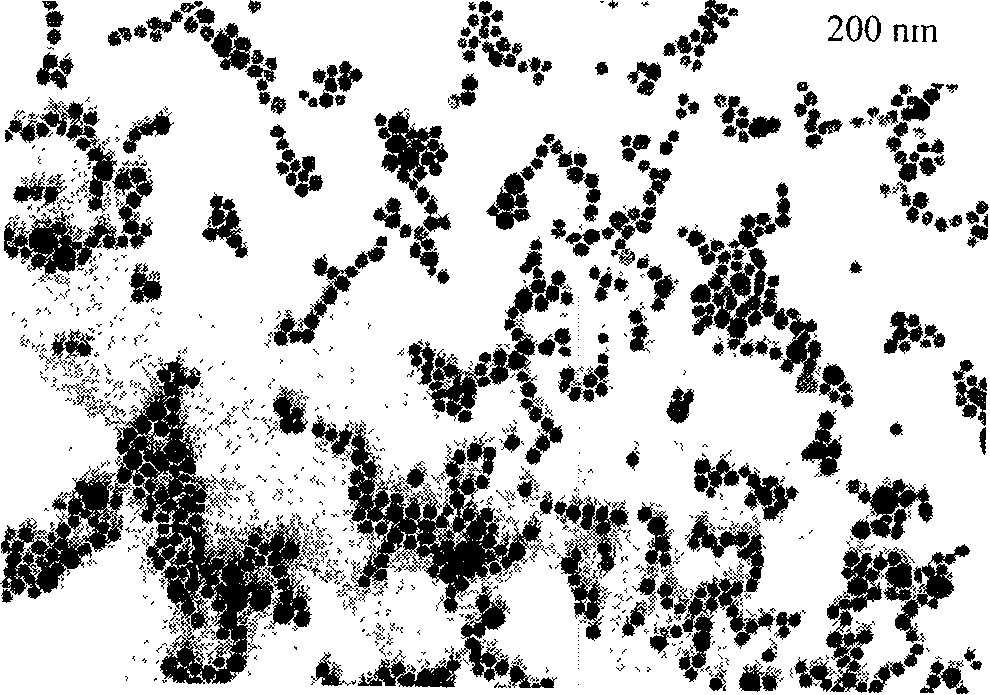

[0031] Embodiment 3: as attached figure 1 , 4 , 7 shown. The preparation of silver sol in this example is the same as the method described in Example 1. Ultrasonic the prepared silver sol at 500W, while stirring at 1000r / min, dropwise add ammonia solution with a mass fraction of 5%, until the pH of the sol is 4; let stand, and filter with 5 layers of slow quantitative filter paper , the filter paper was soaked with ammonia water with a mass fraction of 3%; passivated with a 1,2,3-benzotriazole solution with a mass fraction of 1%; washed 4 times with deionized water, and then washed with absolute ethanol and acetone Each was washed once, and dried under vacuum at 60°C. Gained silver powder has carried out TEM and XRD detection respectively, as Figure 4 , 7 As shown, the particles of the product are basically spherical, with good dispersion, an average particle size of 40nm, and high purity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com