Process for preparing I-clopidogrel hydrogen sulfate

A technology of clopidogrel sulfate and clopidogrel salt, which is applied in the field of preparation of type I clopidogrel sulfate, and can solve problems such as inability to provide stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

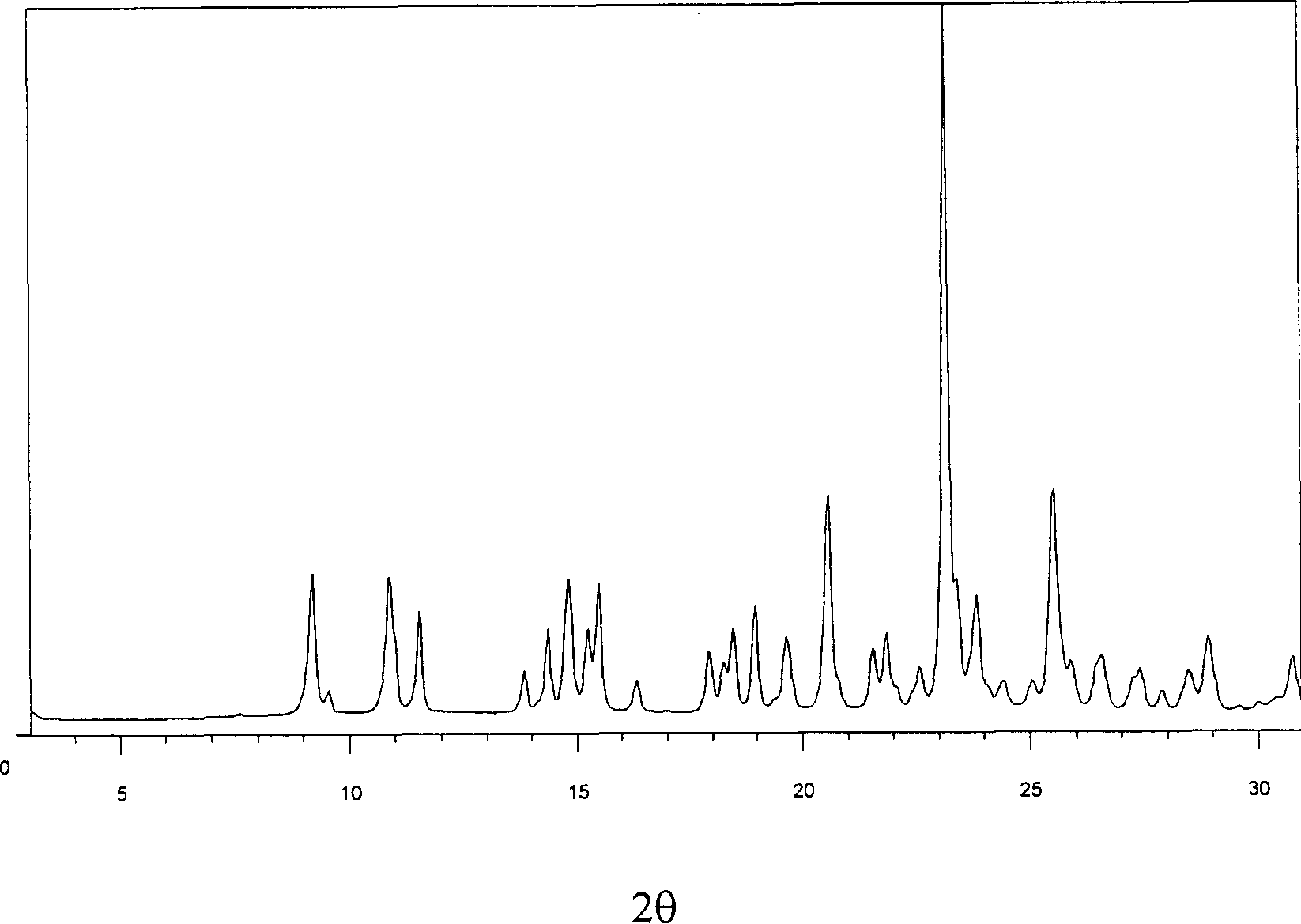

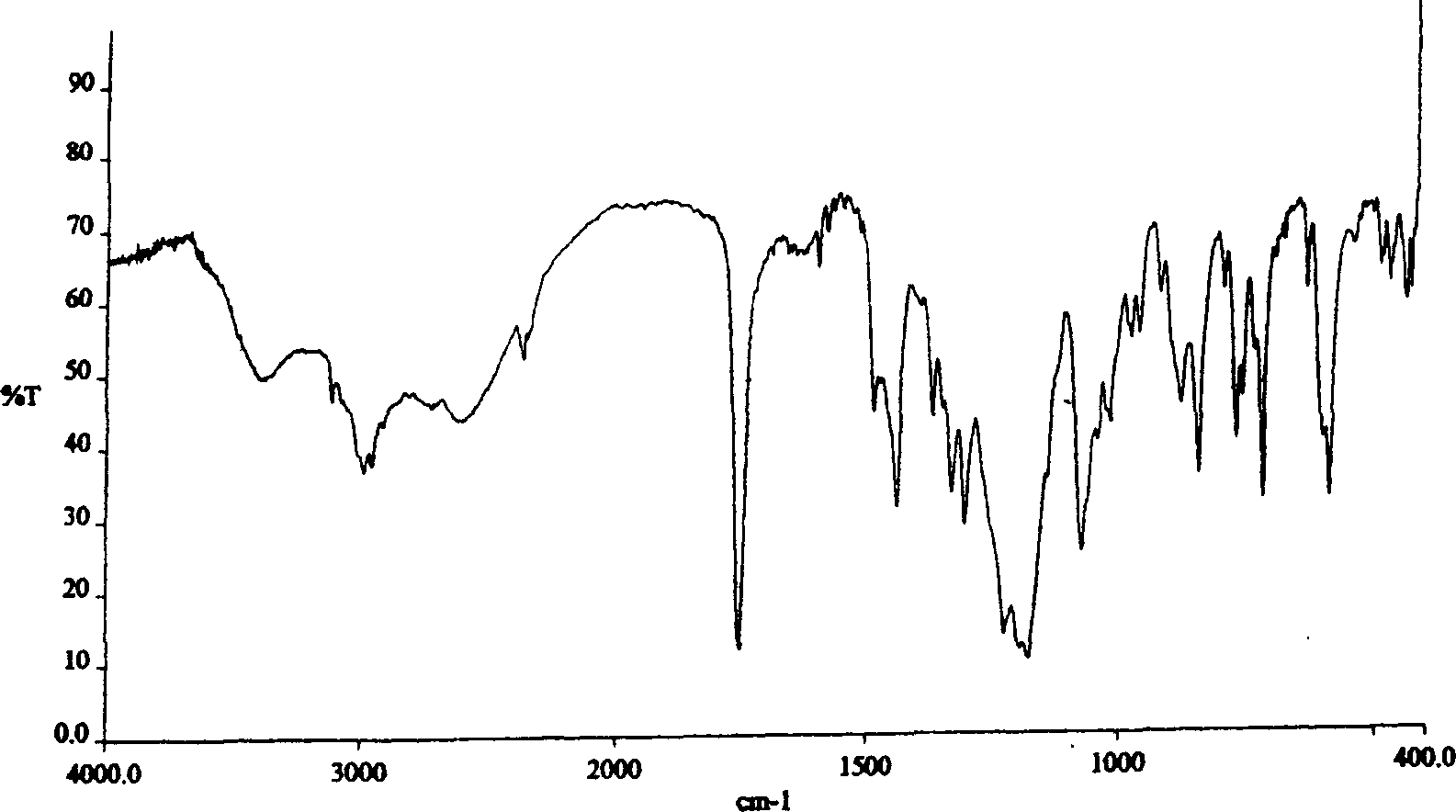

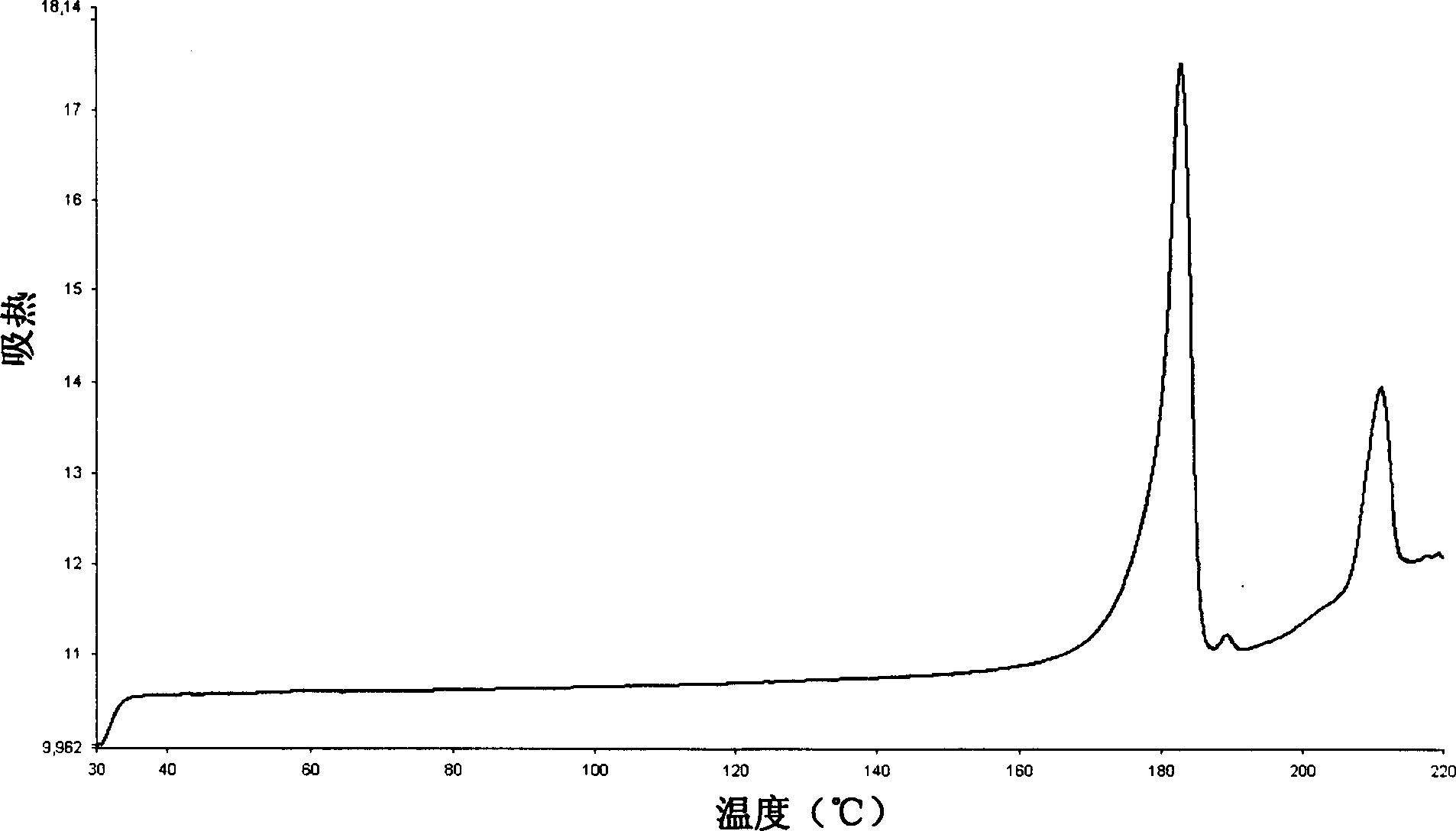

Image

Examples

Embodiment 1

[0022] Under argon protection, 12.6 grams of clopidogrel sulfate (0.03mol) and 300 milliliters of chloroform were added into a 500 milliliter three-necked flask, and under stirring and cooling with ice water, 4.5 grams of potassium carbonate (0.045mol) and An aqueous solution composed of 40 ml of ionic water was stirred until the pH value of the upper layer was greater than 9; the layers were left to stand, the lower organic phase was separated, the upper aqueous layer was extracted once with 150 ml of chloroform, the organic phases were combined, dried with potassium sulfate, and concentrated to dryness , to obtain free clopidogrel base; add tert-butyl methyl ether 300ml to this free clopidogrel base, stir for 1 hour, and completely dissolve the solid residue; 40% sulfuric acid solution, so that clopidogrel and sulfuric acid are salified to generate clopidogrel bisulfate, and the temperature of the mixed solution is controlled between -15 and -5°C during the dropwise addition;...

Embodiment 2

[0025] Under nitrogen protection, 5.39 g (0.01 mol) of clopidogrel camphorsulfonate was added to a 250 ml three-necked flask together with 50 ml of ethylene dichloride, and under stirring and cooling with ice water, 1.48 g of potassium carbonate ( 0.015mol) and 30 ml of ionic water, stirred for one hour, and the pH value of the upper layer was measured to be greater than 9; the lower organic phase was separated after standing for stratification, and the upper aqueous layer was extracted once with 30 ml of dichloroethane, and the organic phases were combined , after being dried with sodium sulfate, concentrated to dryness to obtain free clopidogrel base; add ethyl acetate 100ml to this free clopidogrel base, stir for 1 hour, the solid residue is completely dissolved; the mixture is cooled to -5°C, start to drop 2.2 grams of 90% sulfuric acid to make clopidogrel and sulfuric acid salt into clopidogrel bisulfate, and control the temperature of the mixed solution during the dropwis...

Embodiment 3

[0027] Under nitrogen protection, 7.15 grams of clopidogrel hydrochloride (0.02mol) and 100 milliliters of dichloromethane were added into a 250 milliliter three-necked flask, and under stirring and cooling with ice water, 2.5 grams of sodium carbonate (0.023 mol) were added dropwise. ) and 30 milliliters of ionized water, stirred for one hour, and the pH value of the upper layer was measured to be greater than 9; the layered organic phase was separated, and the upper aqueous layer was extracted once with 50 milliliters of dichloromethane, and the combined organic phases were washed with sulfuric acid After sodium drying, concentrate to dryness to obtain free clopidogrel base; add 150ml of ethyl formate to the free clopidogrel base, stir for 1 hour to completely dissolve the solid residue; cool the mixture to -10°C , start to drop 2 grams of concentrated sulfuric acid to make clopidogrel and sulfuric acid salify to generate clopidogrel bisulfate, and control the temperature of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com