Process for determining hydrocarbon composition of vacuum gas oil by combination of solid phase extraction and mass spectrum

A technology of reduced pressure gas oil and family composition, which is applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of long time, large sample volume, unsuitable for batch and rapid analysis of VGO samples, etc. The effect of shortening analysis time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

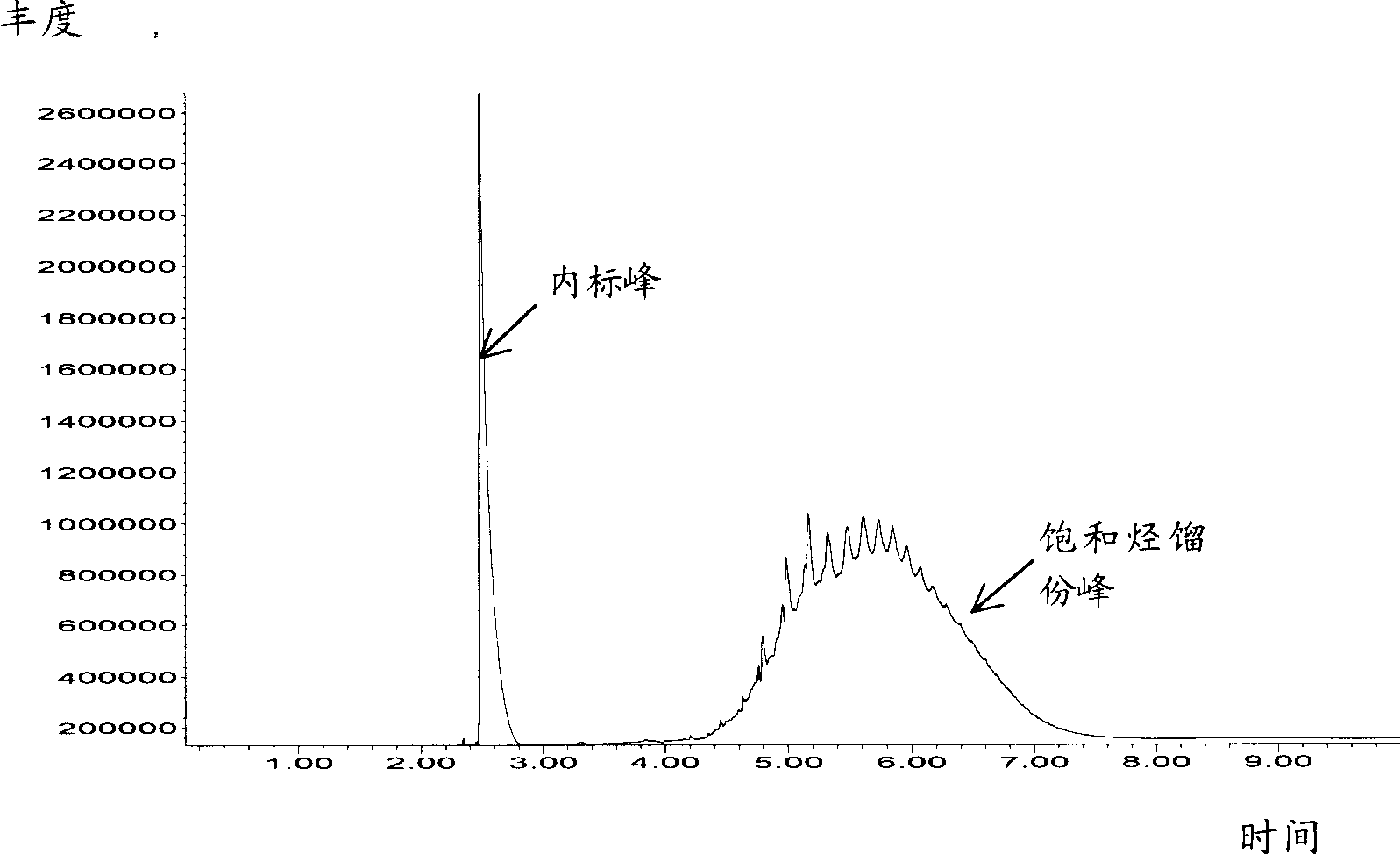

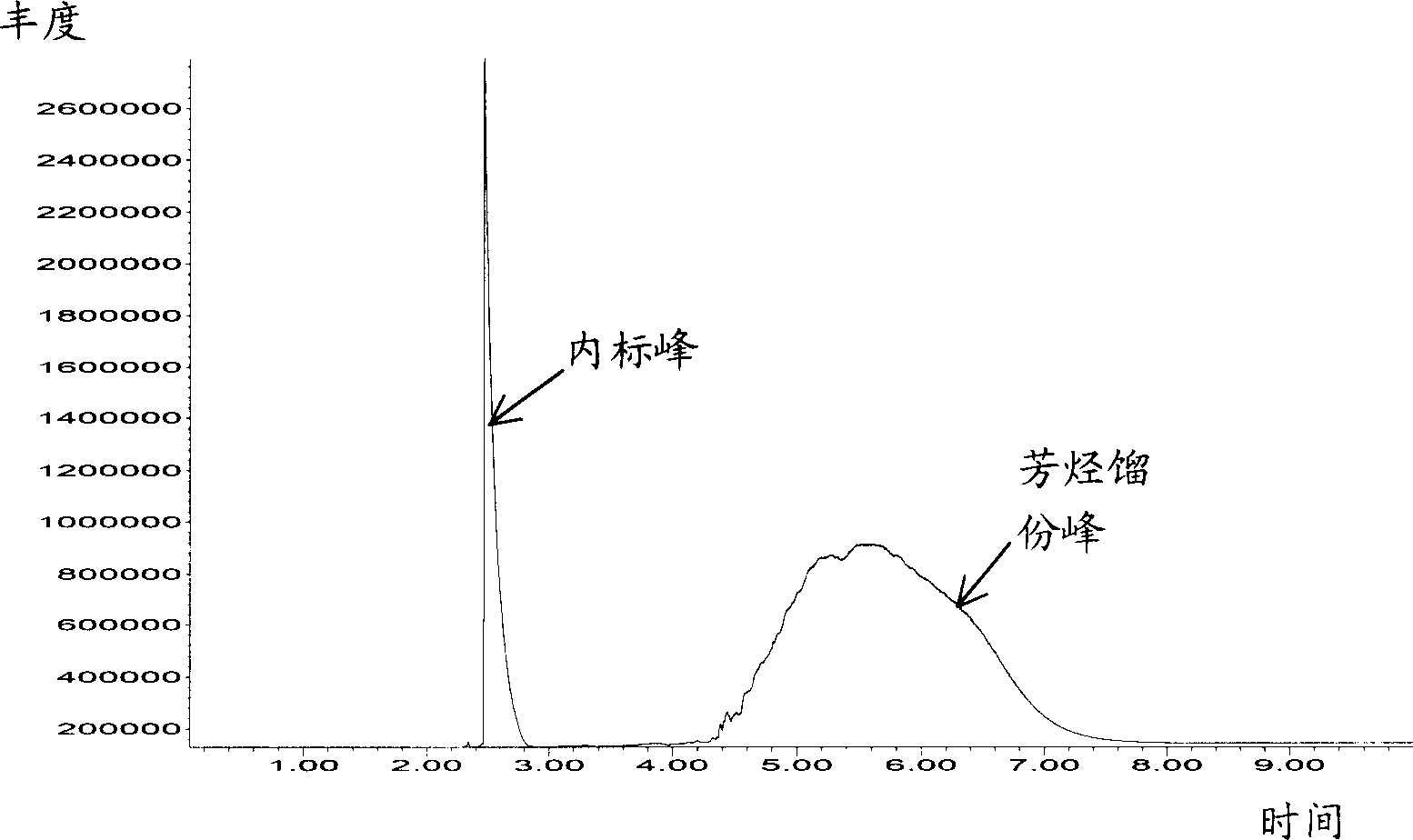

[0043] The applicability of the internal standard method GC-FID of the present invention to determine the relative content of saturated hydrocarbons and aromatic hydrocarbons in VGO samples was investigated.

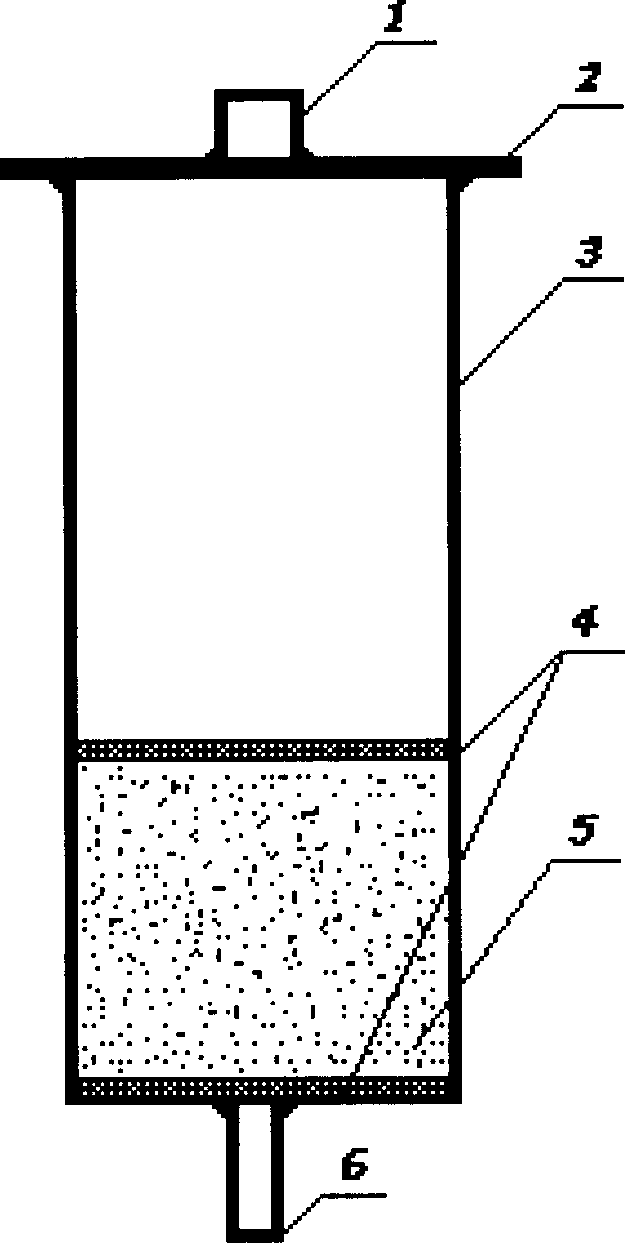

[0044] in such as figure 1 The shown SPE column with a height of 60 mm and an internal diameter of 7.0 mm is packed with 1.8 g of activated silica and has a specific surface area of 600 m 2 / g, the pores with a pore volume of 0.45 ml / g and a pore diameter of 290-330 nm accounted for 60% of the total pore volume.

[0045] According to the method of ASTM D2549, take 2 grams of VGO samples, separate the saturated hydrocarbons, aromatics and colloids, and prepare 4 samples with different contents of saturated hydrocarbons and aromatics after weighing each, and take 0.10 grams of prepared samples Dropped into the solid phase extraction column, the sample is completely absorbed by the stationary phase silica. Then add 2.5 milliliters of n-pentane to the solid-phase extract...

example 2

[0050] The VGO sample was analyzed according to the method of Example 1, except that the VGO sample was dropped into the solid-phase extraction column to extract saturated hydrocarbons, aromatic hydrocarbons and colloids therein. Dry the obtained saturated hydrocarbon and aromatic hydrocarbon extracts in a water bath at 50-60°C for 30 minutes, weigh them at room temperature, then dry them at this temperature for 10 minutes, and weigh them again. Repeat the drying and weighing steps until The solvent in the extract is completely volatilized, and the difference between the two weighing results is no more than 10 mg, which is regarded as a constant weight. Record the mass of saturated hydrocarbons and aromatic hydrocarbons obtained after weighing constant weight, then dry the colloidal solution obtained by extraction in a water bath at 80-90°C in the same way, weigh until the solvent is completely volatilized, and record the mass after weighing constant weight The resulting gum m...

example 3

[0053] The VGO sample was analyzed according to the method of Example 1, except that the VGO sample was dropped into the solid-phase extraction column to extract saturated hydrocarbons, aromatic hydrocarbons and colloids therein. Take 0.5 μL of the extracts of each component added with the internal standard, and pass it into the injection port of the GC-MS instrument, and send a part of the sample to the GC-FID detection system through the diverter valve for chromatographic analysis; the other part The sample is sent to the mass spectrometry detection system to determine the hydrocarbon group composition. Calculate the relative content of saturated hydrocarbons, aromatic hydrocarbons and colloids from the peak area of the gas chromatogram, calculate the hydrocarbon group composition according to the method of ASTM D2425, and then calculate the saturated hydrocarbons and aromatic hydrocarbons in the total content of the two calculated by the GC-FID spectrum The relative conte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com