Surgical fixation hot-softening bandage contg. zinc oxide and its producing method

A production method, zinc oxide technology, applied in bandages, plaster bandages, medical science, etc., can solve problems such as complex processes, and achieve the effects of simple processes, favorable thermoplasticity, and high use strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

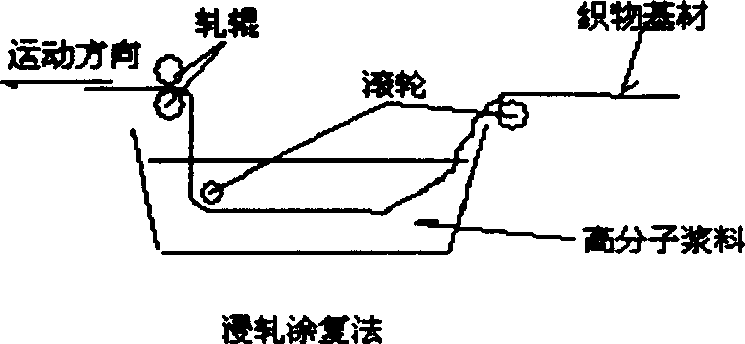

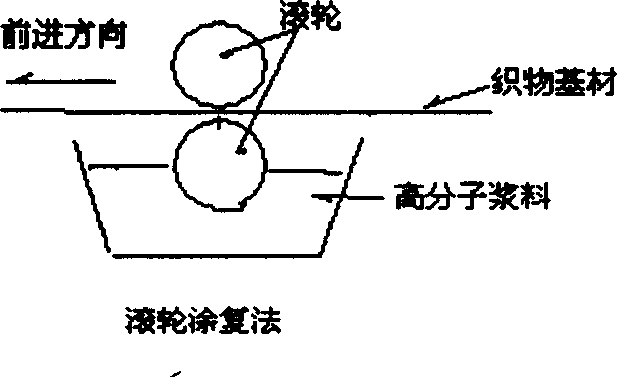

[0024] Embodiment 1: 80 grams of caprolactone-lactic acid copolyester with a molecular weight of 60,000 are dissolved in a mixed solvent of 800 grams of butyl acetate and 200 grams of tetrahydrofuran and heated for dissolution. After it becomes a uniform solution, 3 grams of zinc oxide are added, 5 grams of kaolin, 0.05 grams of phthalocyanine green were stirred and mixed evenly, and the polymer compound was coated on the cotton medical gauze by the roller transfer method. After compounding, 95% of the weight gain of gauze is resin coating.

Embodiment 2

[0025] Embodiment 2: 85 grams of polycaprolactone with a molecular weight of 80,000 are dissolved in a mixed solvent of 700 grams of ethyl acetate and 300 grams of tetrahydrofuran and heated for dissolution. After it becomes a uniform solution, 5 grams of zinc oxide and 4 grams of clay are added. 1 gram of titanium dioxide was stirred and mixed evenly, and the polymer compound was coated on the knitted polyester cloth by the roller transfer method. After the solvent volatilized, a white zinc oxide-containing thermal softening surgical fixation bandage was obtained. After coating, the knitted polyester cloth increased in weight by 105. % for resin coating.

Embodiment 3

[0026] Example 3: 60 grams of trans polyisoprene with a molecular weight of 60,000 was dissolved in 1000 grams of gasoline and heated for dissolution. After it became a uniform solution, 7 grams of zinc oxide and 0.06 grams of phthalocyanine blue were added and stirred evenly. The polymer composite is coated on the knitted acrylic fabric by the padding method. After the solvent evaporates, a blue zinc oxide-containing heat-softened surgical fixation bandage is obtained. After coating, the knitted acrylic fabric increases in weight by 85% to form a resin coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com