Method for preparing photocatalyst of titanium dioxide carried by active carbon

A photocatalyst and titanium dioxide technology, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of TiO2 activity reduction, high preparation cost, and complicated process, so as to improve photocatalytic activity, The effect of simple equipment and simplified preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

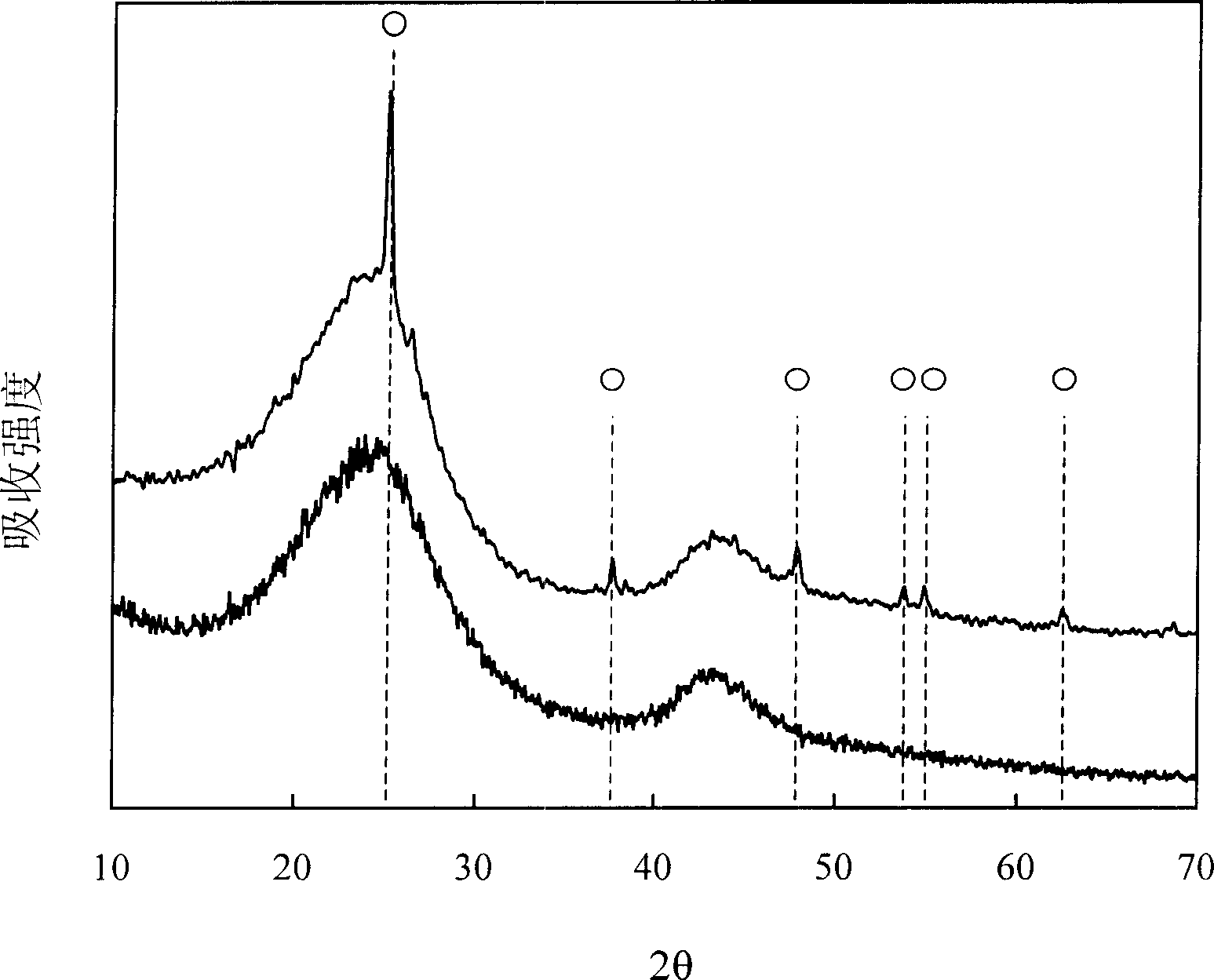

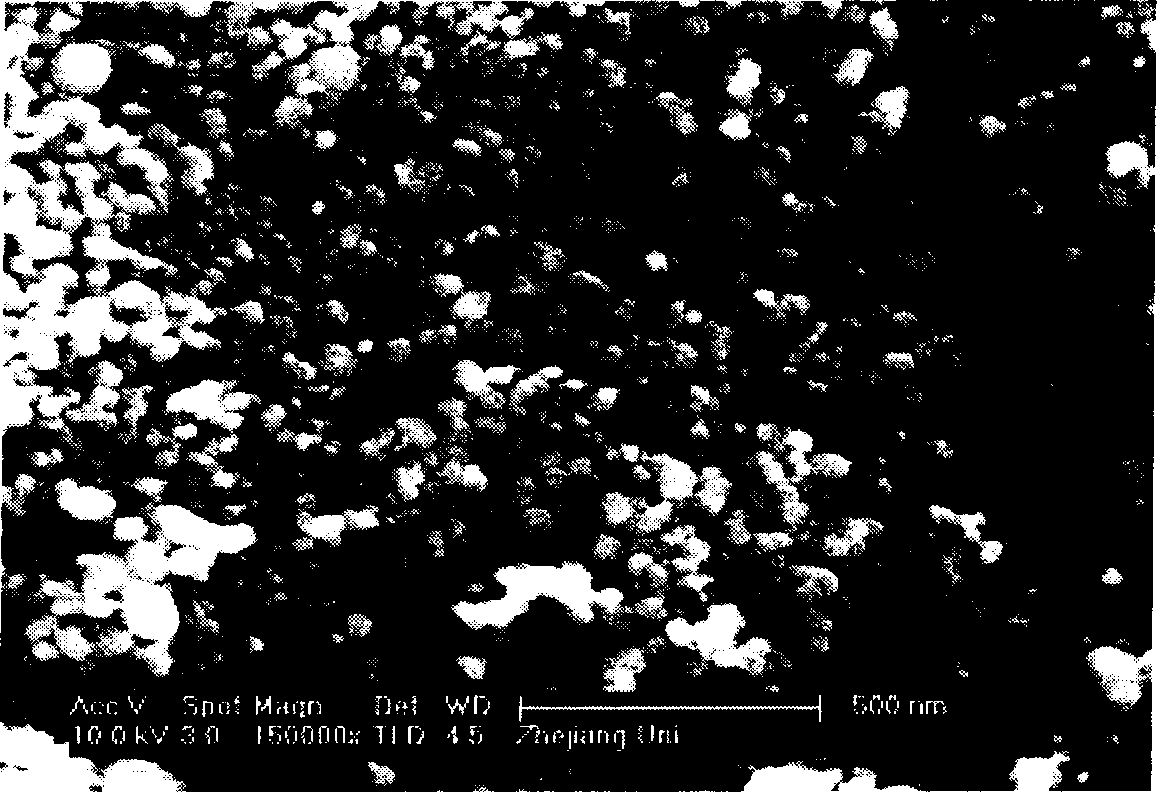

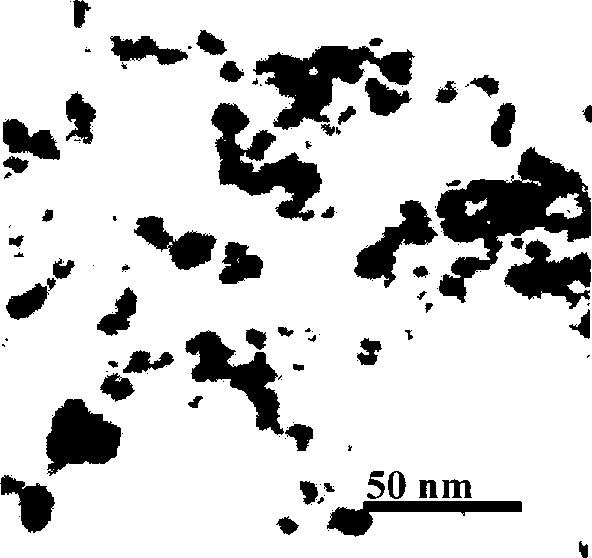

Embodiment 1

[0027] Put 40-60 mesh granular activated carbon into HNO with a concentration of 6mol / L 3 In the solution, boil at 373K for 1 hour to generate oxygen-containing functional groups on the surface of the activated carbon, wash with deionized water after cooling; put the above-mentioned activated carbon into a quartz reactor, feed nitrogen into the reactor, and control the flow rate of nitrogen to 100ml / min, then heated to 423K and maintained for 60 minutes; then heated the reactor to 873K; heated the butyl titanate to 523K, with nitrogen as the carrier gas, and the gas flow rate was 400ml / min, and the butyl titanate was loaded into the reactor In, TiO was deposited on the surface of activated carbon after the decomposition of butyl titanate 2 , After 12 hours of deposition, close the butyl titanate valve, blow nitrogen into the reactor to remove some residual precursors, and calcinate for 3 hours under the protection of nitrogen to prepare activated carbon-supported titanium dio...

Embodiment 2

[0029] Put 40-60 mesh granular activated carbon into HNO with a concentration of 10mol / L 3 In the solution, boil at 573K for 2 hours to generate oxygen-containing functional groups on the surface of the activated carbon, wash with deionized water after cooling; put the above-mentioned activated carbon into a quartz reactor, feed nitrogen into the reactor, and control the nitrogen flow rate of 200ml / min, then heated to 523K and maintained for 15 minutes; then heated the reactor to 773K; heated the isopropyl titanate to 323K, with nitrogen as the carrier gas, the gas flow rate was 400ml / min, and the isopropyl titanate was loaded to In the reactor, TiO is deposited on the surface of activated carbon after the decomposition of isopropyl titanate 2 , After 6 hours of deposition, close the isopropyl titanate valve, blow nitrogen into the reactor to remove some residual precursors, and calcinate for 3 hours under the protection of nitrogen to prepare activated carbon-supported titan...

Embodiment 3

[0031] Put 40-60 mesh granular activated carbon into HNO with a concentration of 1mol / L 3 In the solution, boil at 373K for 0.5h to generate oxygen-containing functional groups on the surface of the activated carbon, wash with deionized water after cooling; put the above-mentioned activated carbon into a quartz reactor, pass argon into the reactor, and control the argon The flow rate is 50ml / min, then heated to 323K and maintained for 30 minutes; then the reactor is heated to 1073K; the isopropyl titanate is heated to 423K, with argon as the carrier gas, the gas flow rate is 800ml / min, and the isopropyl titanate Propyl ester is loaded into the reactor, and TiO is deposited on the surface of activated carbon after decomposition of isopropyl titanate 2 , After 10 h of deposition, close the valve of isopropyl titanate, pass argon gas into the reactor to remove the remaining part of the precursor, and calcined for 3 h under the protection of argon gas to prepare activated carbon-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com