Process of preparing total iridoid glycoside with cape jasmine fruit

A technology for total iridoid glycosides and fruits, applied in the field of medicine, can solve the problems of complicated operation, reduced yield and high cost, and achieve the effects of simple preparation process, reduced elution and reduced loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] 1. Preparation of gardenia fruit crude extract: take 500g of dried gardenia fruit medicinal material powder, extract twice with 10 times the amount of 50% ethanol under reflux, each time for 2 hours, filter, combine the filtrates, concentrate under reduced pressure at 60°C until dilute paste, and vacuum-dried to obtain the crude extract of Gardenia fruit, with a yield of 26.6%.

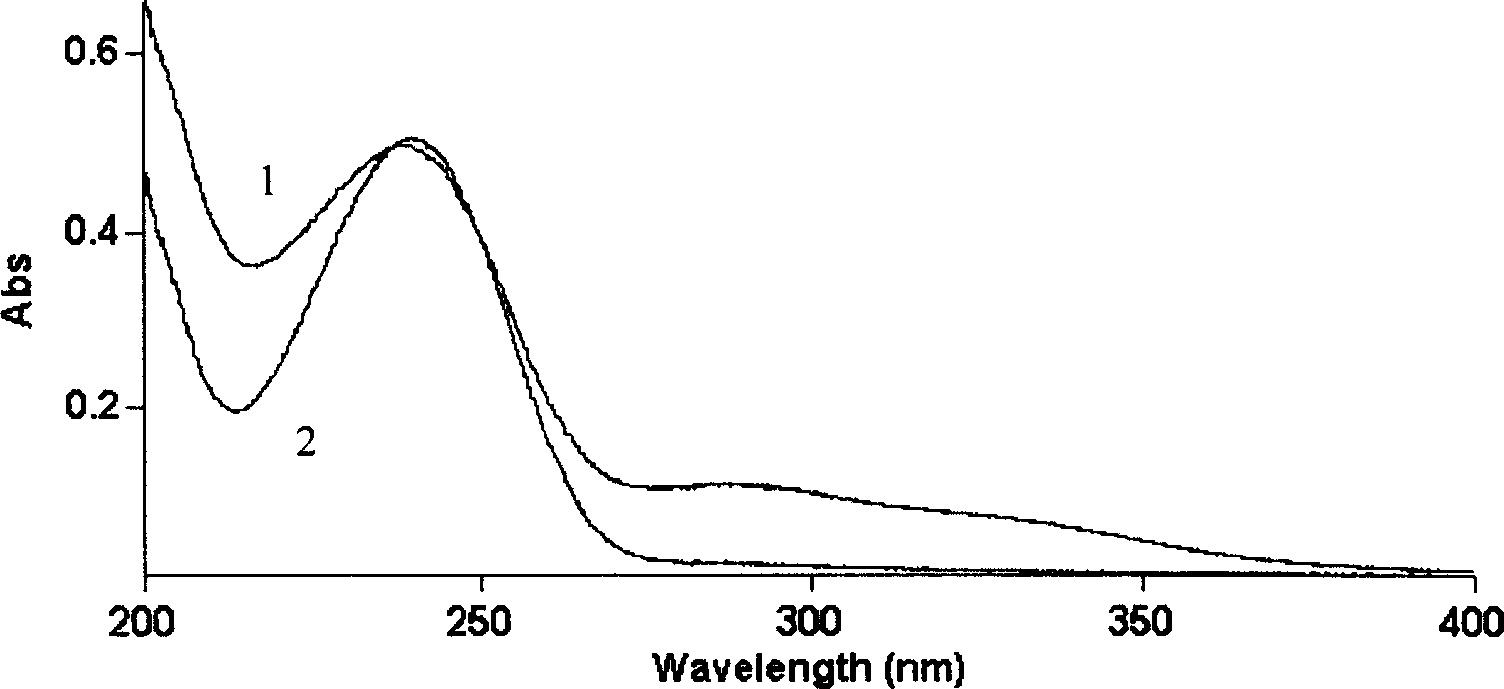

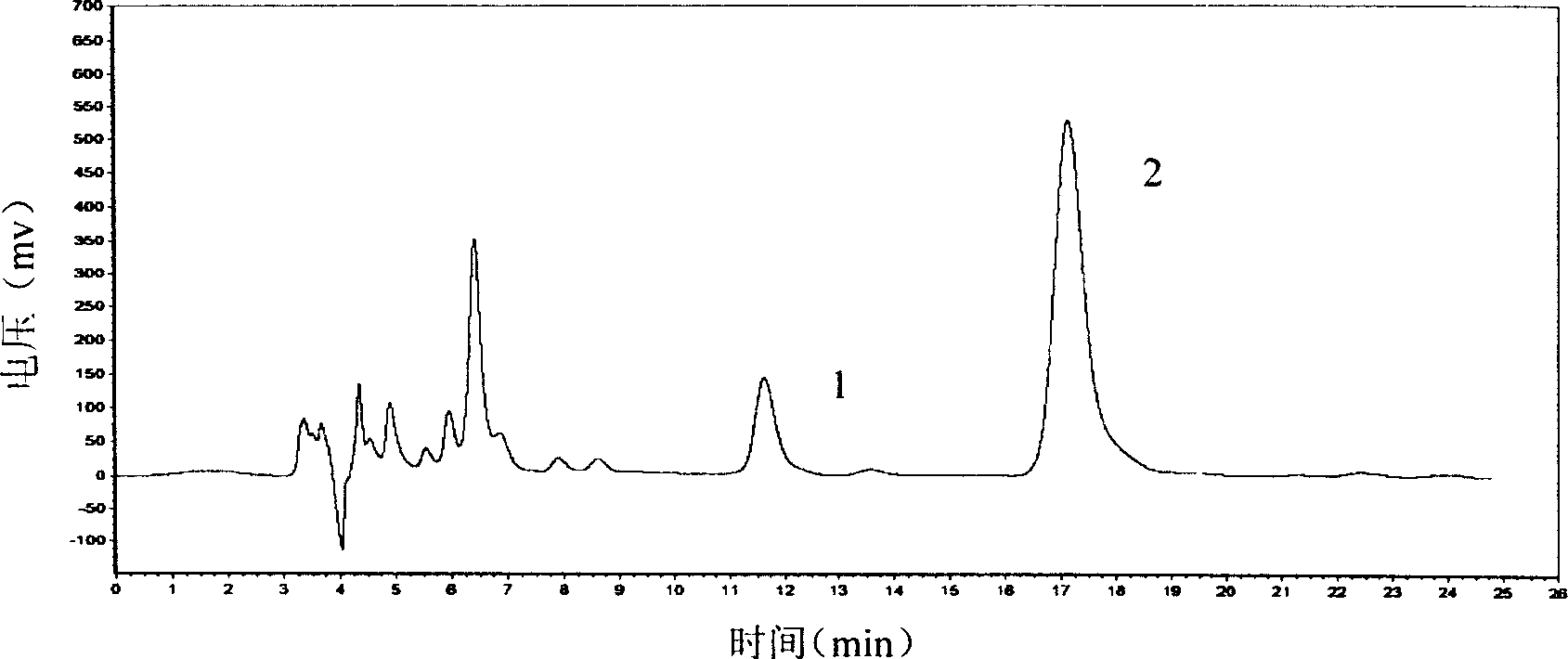

[0016] 2. Purification: take the above-mentioned gardenia fruit crude extract, add water and suspend, and the total volume is 2000ml. Add it to a 1300 macroporous adsorption resin chromatography column equipped with 1500 g of pretreated, and absorb for 2 hours after loading the sample. Elute with 1500ml of water (discard). Then eluted with 6000ml of 20% ethanol, and the ethanol eluted fraction was concentrated under reduced pressure, then vacuum-dried (60° C.) to obtain 46.59 g of total iridoid glycoside powder, with a yield of 9.3%. Gained powder is detected by ultraviolet spectrophotometry ...

Embodiment 2

[0018] 1. Preparation of crude gardenia fruit extract: Take 500 g of dried gardenia fruit medicinal material powder, extract twice with 10 times the amount of water, 2 hours each time, filter, combine the filtrates, concentrate under reduced pressure at 60°C to dilute extract, The crude extract of Gardenia fruit was obtained by vacuum drying with a yield of 28.7%.

[0019] 2. Purification: take the above-mentioned gardenia fruit crude extract, add water and suspend, and the total volume is 2000ml. Add it to a 1300 macroporous adsorption resin chromatography column equipped with 1500 g of pretreated, and absorb for 2 hours after loading the sample. Elute with 1500ml of water (discard). Then elute with 4000ml 30% ethanol, after the ethanol eluate fraction is concentrated under reduced pressure, vacuum-dry (60 ℃), obtain the total iridoid glycosides powder 49.30g, record the total iridoid glycosides purity to be 80.8%, The yield is 9.9%, and the content of geniposide is 64.8%. ...

Embodiment 3

[0021] 1. Preparation of gardenia fruit crude extract: Take 500g of dried gardenia fruit crude powder, soak and extract with 10 times the amount of 50% ethanol for 2 times, each time for 2 hours, filter, combine the filtrate, concentrate under reduced pressure at 60°C to dilute paste, and dried in vacuum to obtain the crude extract of Gardenia fruit, with a yield of 20.3%.

[0022] 2. Purification: take the above-mentioned gardenia fruit crude extract, add water and suspend, and the total volume is 2000ml. Add it to the chromatographic column equipped with 1500g pretreated AB-8 macroporous adsorption resin, and absorb for 2 hours after loading the sample. Elute with 1500ml of water (discard). Then elute with 8000ml 10% ethanol, after the ethanol eluate fraction is concentrated under reduced pressure, vacuum-dry (60 ℃), obtain total iridoid glycosides powder 40.62g, record total iridoid glycosides purity to be 89.2%, The yield is 8.1%, and the content of geniposide is 55.2%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com