Inorganic nano combined fiber reinforced polyimide composite material and its preparing method

A polyimide and fiber-reinforced technology, which is applied in the field of inorganic nanocomposite fiber-reinforced polyimide composite materials and its preparation, can solve the problems of affecting the performance of materials and the brittleness of composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

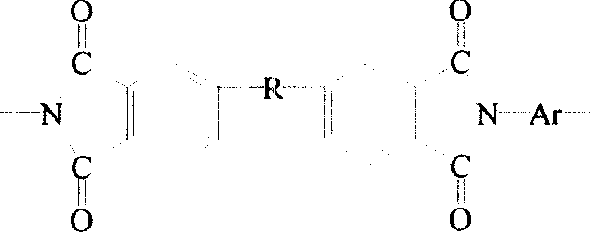

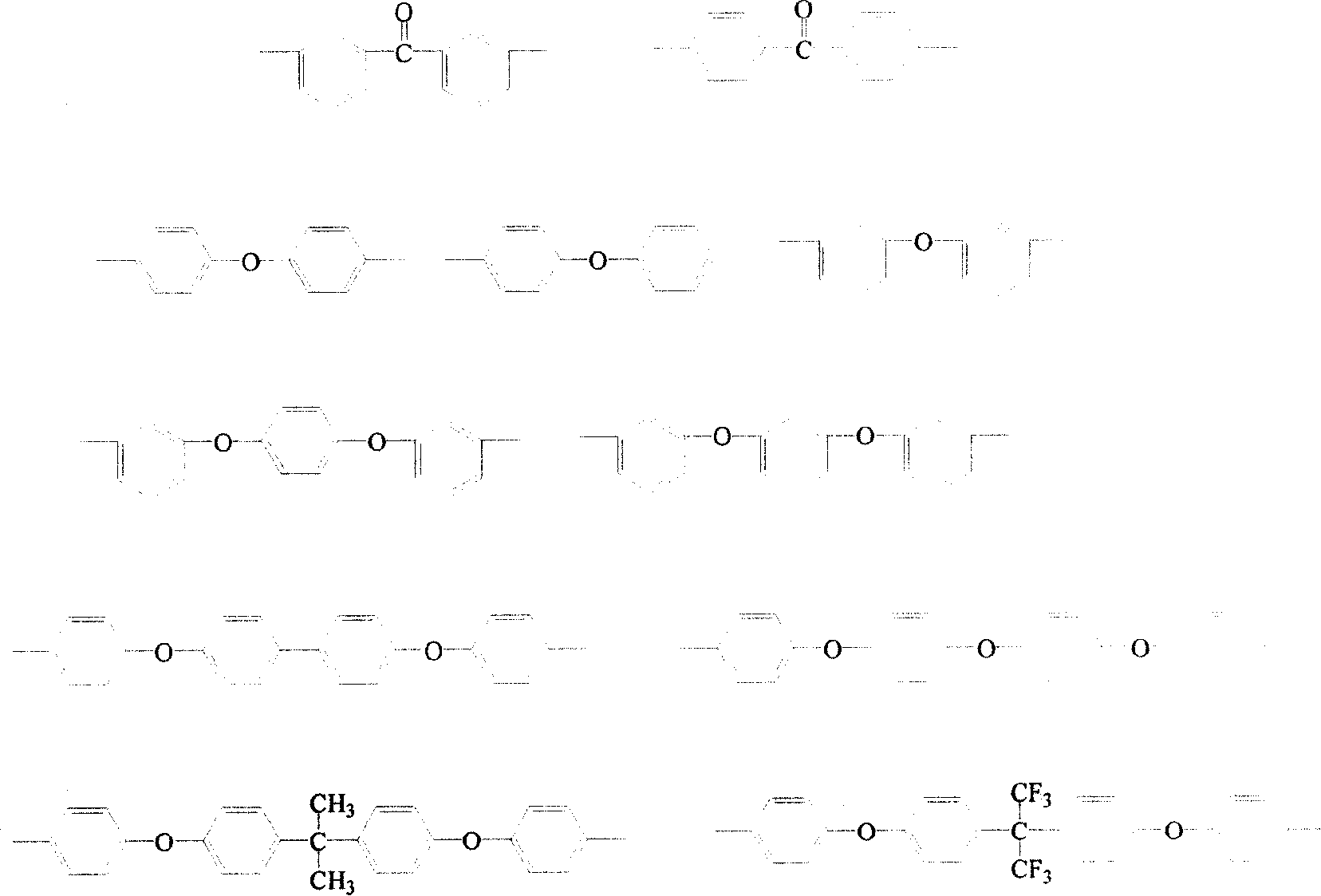

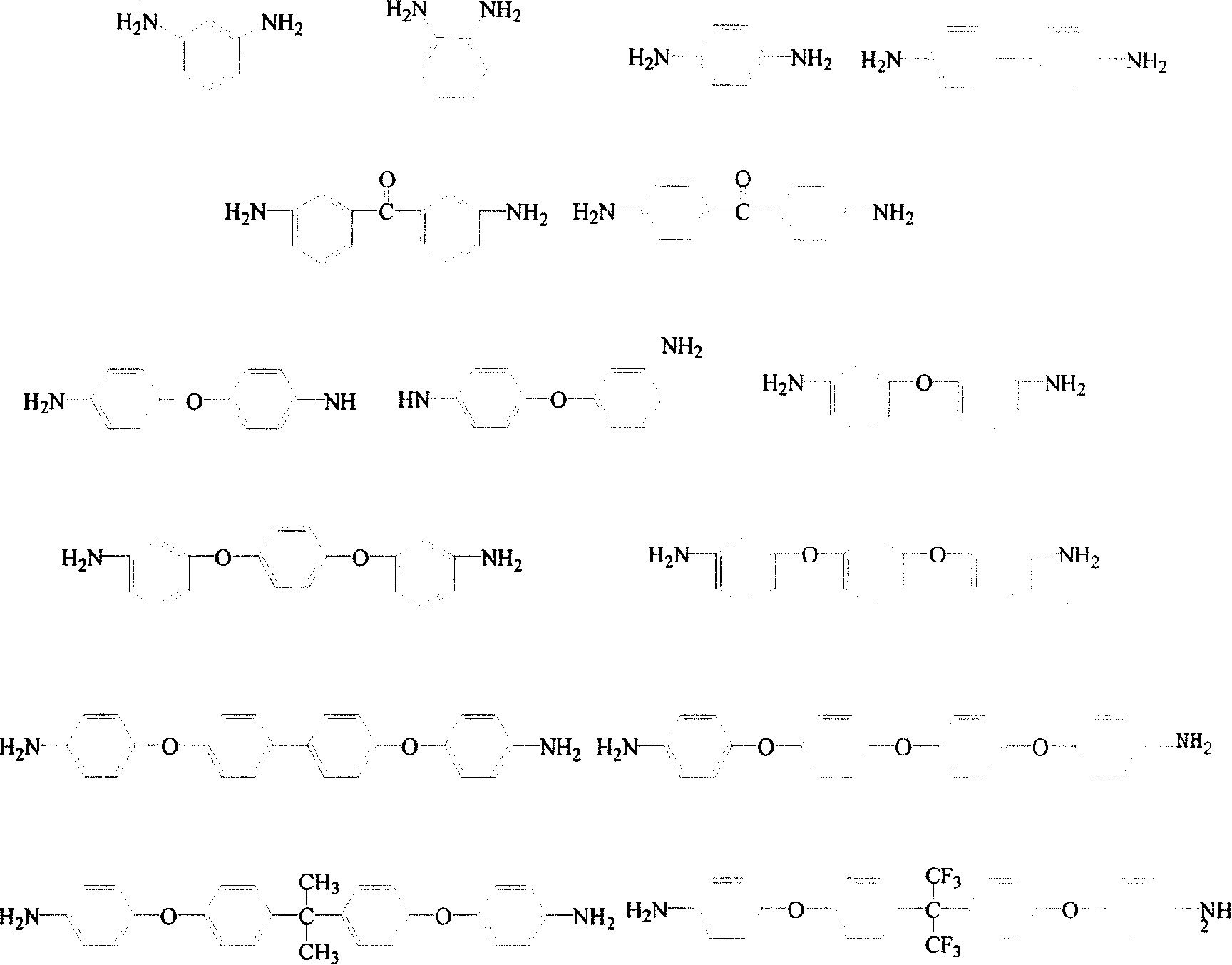

Method used

Image

Examples

Embodiment 1

[0070] Unidirectional carbon fiber reinforced polyimide composites were prepared by ODPA / 3,4'-ODA system.

[0071] (1) Preparation of polyamic acid solution compounded with inorganic nanoparticles.

[0072] First, the nano-TiO treated by plasma for 10 min 2 The particles were dissolved in DMAc solvent, and mechanically stirred for 2 hours in the case of ultrasonic-assisted dispersion to obtain a suspension solution in which nanoparticles were uniformly dispersed; then, 0.100 mol of diamine 3,4 was added to the DMAc suspension containing nanoparticles '-ODA to dissolve completely; then, add 0.0981mol dianhydride ODPA to the mixed solution, stir mechanically to make it fully react with 3,4'-ODA, and use an ice-water bath to ensure that the reaction temperature is controlled at 0-25°C ; After 8 hours of sufficient reaction, the final polyimide Mn = 25000, solid content of 20 wt%, polyamic acid solution composited with inorganic nanoparticles.

[0073] (2) Preparation of fiber-r...

Embodiment 2

[0076] Preparation of unidirectional carbon fiber reinforced polyimide composites with BPDA / 3,4'-ODA system.

[0077] According to the same method as in Example 1, first use 0.0982mol of BPDA and 0.100mol of 3,4'-ODA as monomers, in the DMAc suspension containing nanoparticles, prepare the final polyimide Mn = 25000, and polyamic acid solution compounded with inorganic nanoparticles. The polyimide preformed film is obtained through far-infrared imidization at 200°C. The polyimide preformed film is filled with 0.1wt% of carbon nanotubes, so that the polyimide preformed film has high modulus, high strength and antistatic properties. The preformed film and carbon fiber (M40B) layers are cut and laminated alternately, placed in a mold and molded on a hot press. The specific process is: directly rise from room temperature to 280°C, keep warm for one hour, and exhaust 3 times; raise the temperature from 280°C to 300°C, start to pressurize during the heating process, the pressure i...

Embodiment 3

[0079] Unidirectional carbon fiber reinforced polyimide composites were prepared by BTDA / 3,4'-ODA system.

[0080] According to the same method as in Example 1, first with 0.09838mol of BTDA and 0.100mol of 3,4'-ODA as monomers, in the DMAc suspension containing nanoparticles, the final polyimide Mn=30000 was prepared, and a polyamic acid solution compounded with inorganic nanoparticles. The polyimide preformed film is obtained through thermal imidization at 200°C. The polyimide preformed film is filled with 1.0wt% nanometer AlN particles, so that the polyimide preformed film has high modulus, high strength and thermal conductivity. The preformed film and carbon fiber (T700) layers are cut and laminated alternately, placed in a mold and molded on a hot press. The specific process is: directly rise from room temperature to 270°C, keep warm for one hour, and exhaust 3 times; heat up from 270°C to 300°C, start to pressurize during the heating process, the pressure is 2-10MPa, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com