Figured coke and its production method

A technology of coke powder and hot pressing, applied in the field of coke molding, can solve the problems of waste of resources, many harmful impurities, less coking coal reserves, etc., and achieve the effects of concentrated heat generation, uniform particle size and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

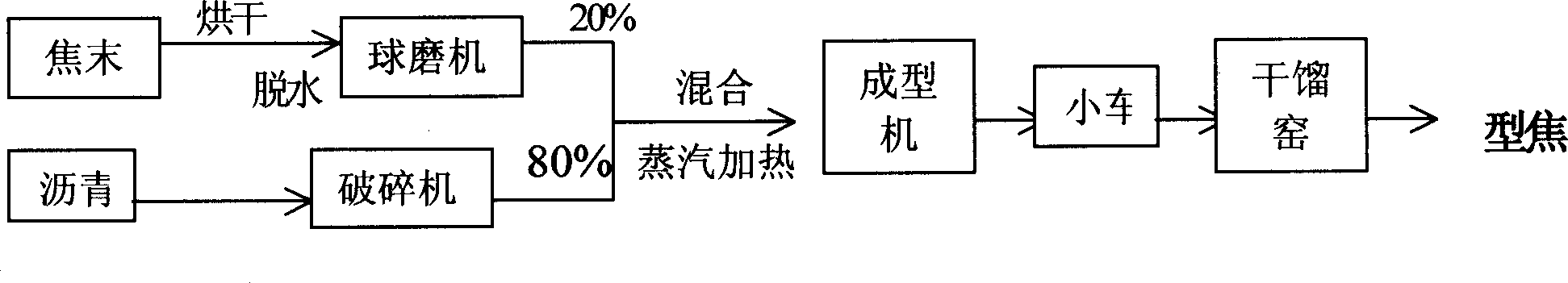

Embodiment 1

[0018] Example 1. Utilize coke powder and pitch to process molded coke. The technological process is as follows: the coke powder is dried by a dryer to remove moisture, and the moisture content is ≤4%; it is ground in a ball mill, and the particle size is between 0.2-1mm. The asphalt produced by tar processing enters the crusher and is crushed until the particle size is between 1-3mm; the coke powder and asphalt are mixed at a weight ratio of 20:80, enter the kneader, and be directly heated by steam. Stir while heating until the bitumen is completely melted. Enter the forming machine, and roll forming (also can be formed by friction press). Blockiness and shape are adjusted as desired. The formed material is put into the retort pit, covered with yellow sand, heated to 1100°C for retort treatment, and the finished coke is the finished product after leaving the pit.

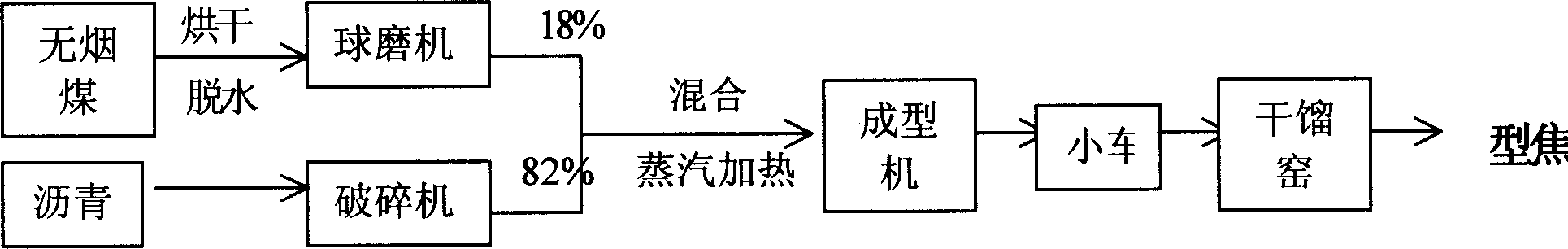

Embodiment 2

[0019] Example 2. Formed coke is processed from anthracite and pitch. The technological process is as follows: the anthracite is dried by a dryer to remove moisture, and the moisture content is ≤4%; it is ground into a ball mill, and the particle size is between 0.2-1mm. The asphalt produced by tar processing enters the crusher and is crushed until the particle size is between 1-3mm. The anthracite and asphalt are mixed at a weight ratio of 20:80, then enter the kneader, and are directly heated by steam. Stir while heating until the bitumen is completely melted. Enter the forming machine, and roll forming (also can be formed by friction press). Blockiness and shape are adjusted as desired. The formed material is put into the retort pit, covered with yellow sand, heated to 1100°C for retort treatment, and the finished coke is the finished product after leaving the pit.

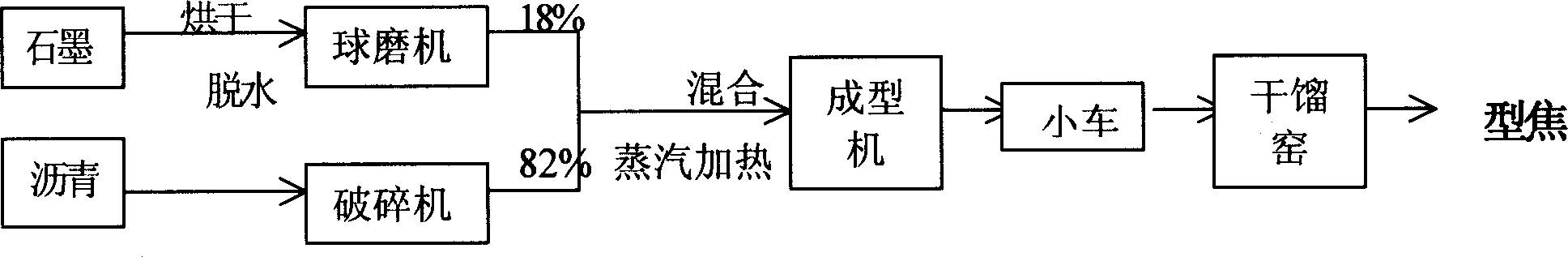

Embodiment 3

[0020] Example 3. Form coke is processed using graphite and pitch. The technological process is as follows: the graphite is dried by a dryer to remove moisture, and the moisture content is less than or equal to 4%; it is ground into a ball mill, and the particle size is between 0.2-1mm. The asphalt produced by tar processing enters the crusher and is crushed until the particle size is between 1-3mm. The graphite and asphalt are mixed at a weight ratio of 20:80, and then enter the kneader and directly heated by steam. Stir while heating until the bitumen is completely melted. Enter the forming machine, and roll forming (also can be formed by friction press). Blockiness and shape are adjusted as desired. The formed material is put into the retort pit, covered with yellow sand, heated to 1100°C for retort treatment, and the finished coke is the finished product after leaving the pit.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com