Process for preparing composite proton exchange film by alkali metal ion type perfluoro sulfonate resin

A technology of perfluorosulfonic acid resin and alkali metal ions, applied in chemical instruments and methods, membrane technology, organic diaphragms, etc., to achieve good application effect and good air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

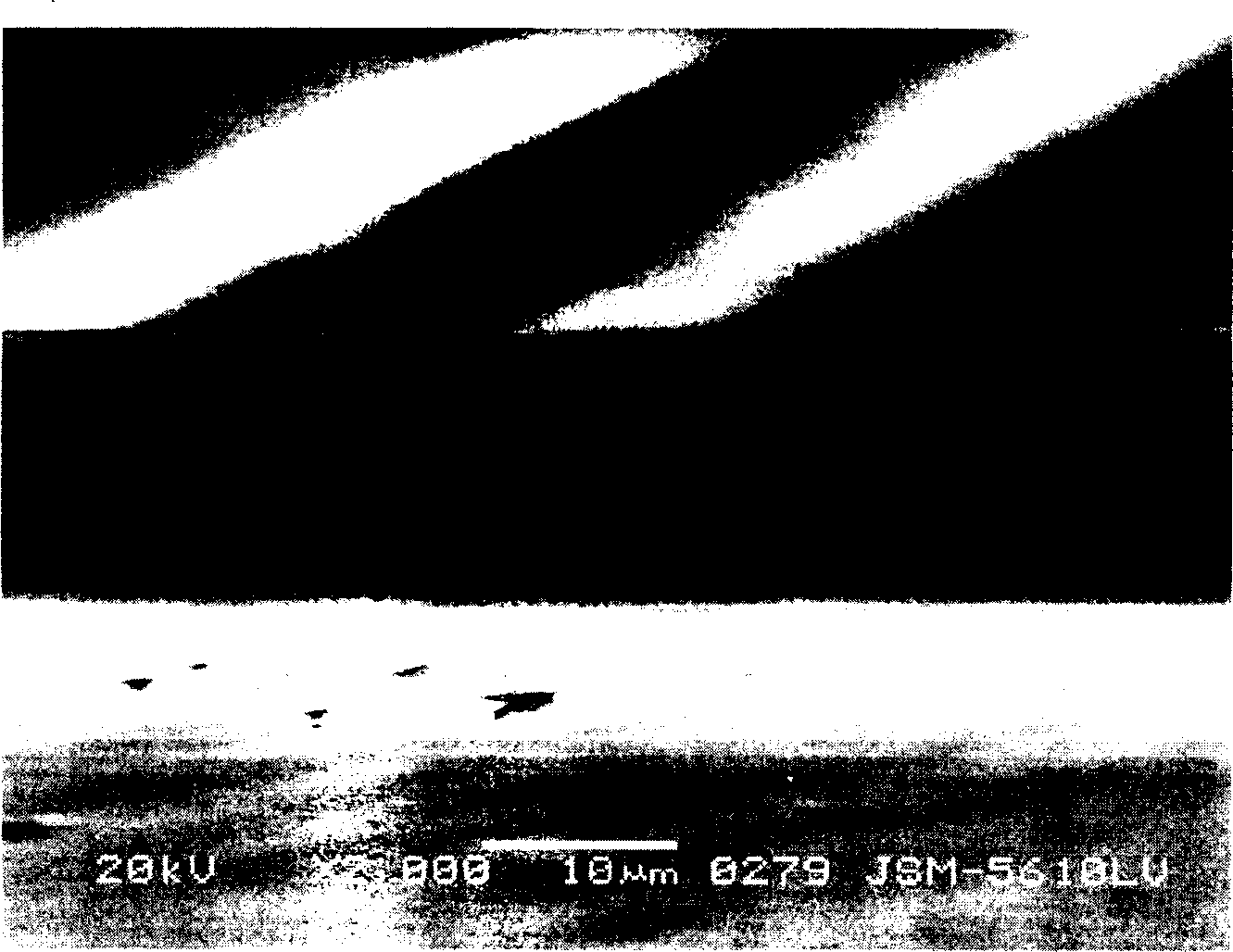

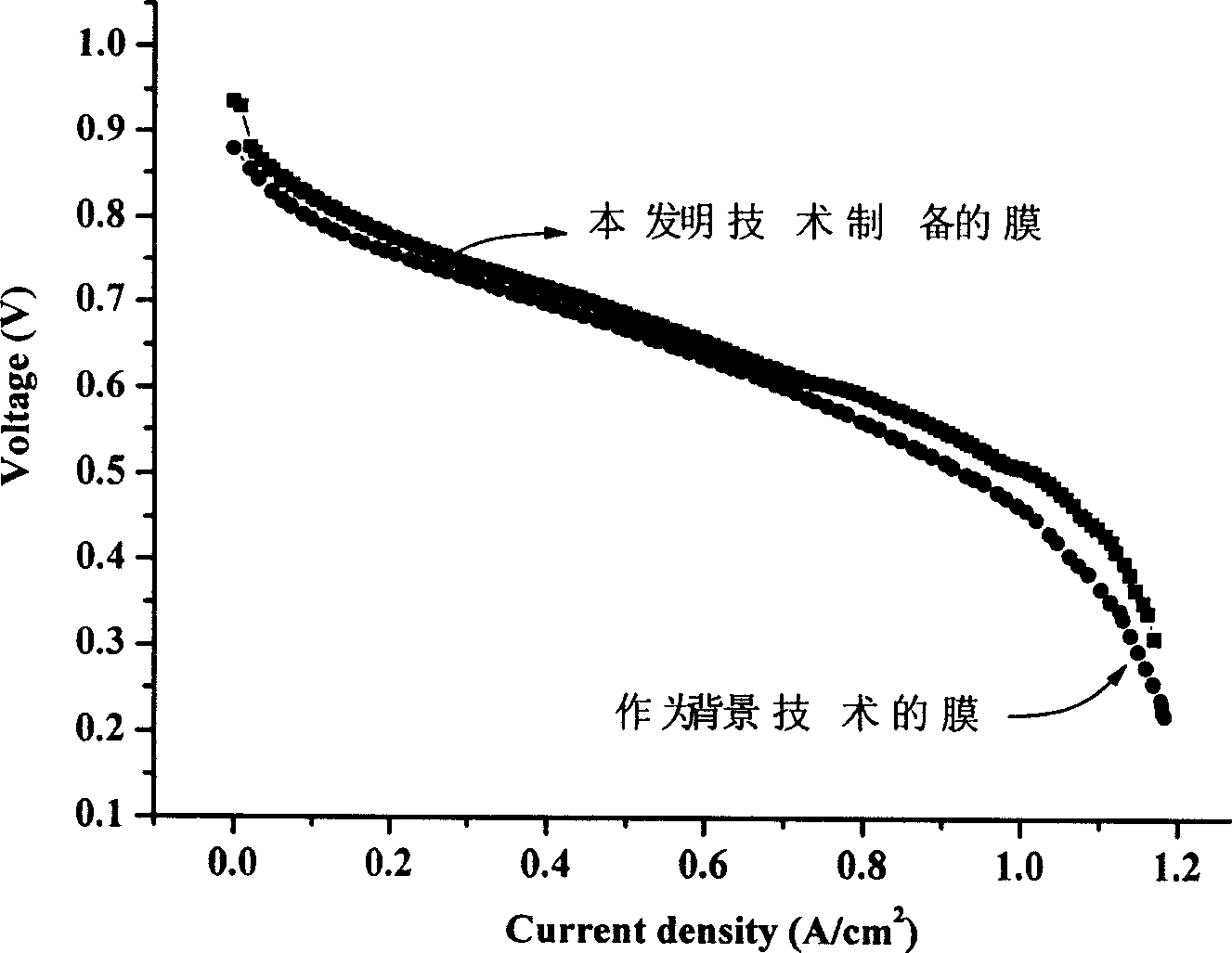

[0023] Get 50mL deionized water, 100mL ethanol, 5gNaCl, stir to make it mix evenly, obtained the alcohol-water mixed solution of NaCl; Get the Nafion perfluorosulfonic acid resin (EW value 1100) that 10gDupont company produces, 200mL propanol, in autoclave Dissolve in 22Mpa and 230°C to obtain a perfluorosulfonic acid resin solution, then add 5g of octylphenol polyethoxyethanol as an active agent; titrate the NaCl alcohol-water mixed solution into the prepared resin alcohol solution to the pH value of the resin solution It is 7.5, obtains Na type resin alcohol solution; The clean porous polytetrafluoroethylene (PTFE) that thickness is 15um is placed in this solution and soaks for 5 minutes, then takes out and adopts double-wheel wheel to roll and roll once, and the film after rolling is placed Put it into a vacuum drying oven, adjust the temperature to 300°C, and heat-treat for 1 minute; repeat this process 3 times to obtain a transparent composite film; soak the composite film...

Embodiment 2

[0029] Take 50mL of deionized water, 50mL of propanol, 70mL of isopropanol, and 8g of KCl, stir to make them evenly mixed, and obtain an alcohol-water mixed solution of KCl; take 10g of perfluorosulfonic acid resin (chinafion, EW900) produced by Shandong Dongyue Company , 150mL propanol, 30mL ethanol to prepare a perfluorosulfonic acid resin solution, then add 3g of alkyl benzyl end-capped phenol ether as an active agent; titrate the alcohol-water mixed solution of KCl into the prepared resin-alcohol solution to pH Value is 7.5, obtains K-type resin alcohol solution; Place the clean porous polytetrafluoroethylene (PTFE) that thickness is 20um (PTFE) in this solution and soak for 3 minutes, then take out and adopt double-wheel wheel to roll and roll once, the film after rolling Put it into a vacuum drying oven, adjust the temperature to 290°C, and heat-treat for 5 minutes; repeat this process twice to obtain a transparent composite film; soak the composite film in ethanol for 10...

Embodiment 3

[0031] Take 150mL propanol, 10gCsCl, stir to mix them evenly, and obtain the alcohol-water mixed solution of CsCl; take 12g F-type perfluorosulfonic acid resin produced by Dupont, 80mL propanol, and 80mL ethanol to obtain a perfluorosulfonic acid resin solution , and then add 4g of dialkyl-capped alcohol ether as an active agent; the alcohol-water mixed solution of CsCl is titrated into the prepared resin alcohol solution, so as to obtain the Cs type resin alcohol solution; the clean porous polytetrafluoroethylene with a thickness of 10um Ethylene (PTFE) is immersed in this solution for 10 minutes, then taken out and rolled by double-wheel rolling, the rolled film is placed in a vacuum drying oven, adjusted to 160°C, and heat-treated for 2 minutes; repeat this process 5 times , a transparent composite membrane was obtained; the composite membrane was soaked in ethanol for 8 minutes, then soaked in boiling deionized water for 8 minutes, dried naturally and then baked in a drying...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com