Method for preparing polysilicon

A polysilicon and amorphous silicon thin film technology, applied in semiconductor/solid state device manufacturing, electrical components, circuits, etc., can solve the problems of reducing on-state current and device stability, low hydrogen content of polysilicon thin film, and small grain size, etc. Achieve the effect of shortening the crystallization cycle and reducing the substrate temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

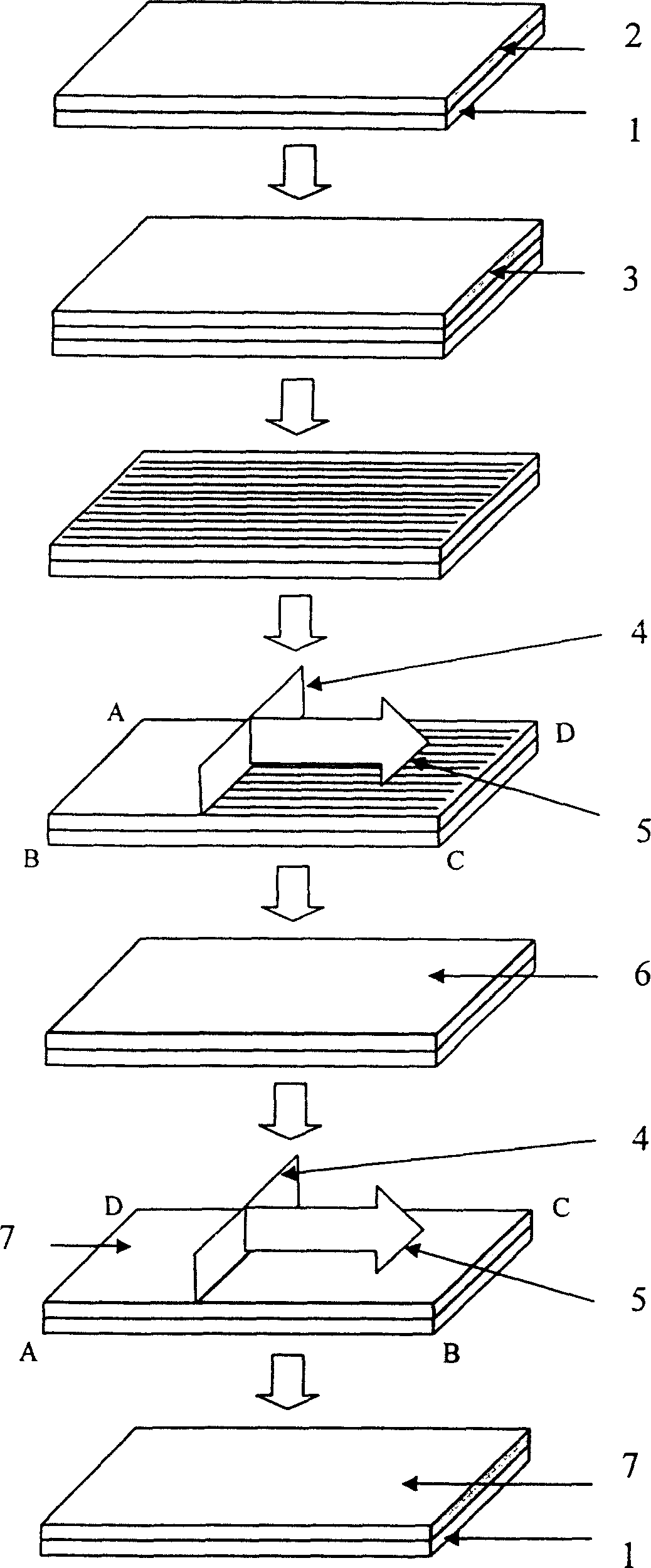

[0023] A 50nm-thick amorphous silicon film (a-Si) 2 was deposited on a common glass substrate 1 by plasma enhanced chemical vapor deposition (PECVD), the substrate temperature was 220°C, and the radio frequency power density was 0.03W / cm 2 , the gas flow rate is 15 sccm, and the reaction chamber pressure is 80Pa.

[0024] The above-mentioned amorphous silicon sample is placed in a magnetron sputtering table to sputter a 5nm metal nickel film 3, the substrate temperature is 150°C, and the radio frequency power density is 0.03W / cm 2 , the background vacuum is 2×10 -4 Pa.

[0025] The metal nickel thin film 3 is photoetched into a line shape with a width of 2 μm and a pitch of 4 μm using ultraviolet lithography technology.

[0026] Use a XeCl (308nm) laser annealing system to perform a laser annealing on the sample at room temperature, make the laser knife 4 perpendicular to the nickel line, place the sample in the laser knife scanning direction 5 parallel to the nickel line, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com