Size exclusion chromatography method for separating biomacromolecule of preparation type transverse electric field

A technology of biological macromolecules and transverse electric field, applied in the field of biological product processing and separation, can solve the problems of large cooling load, long distance, product loss, etc., and achieve the effect of avoiding high-voltage power supply, broad application prospects and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

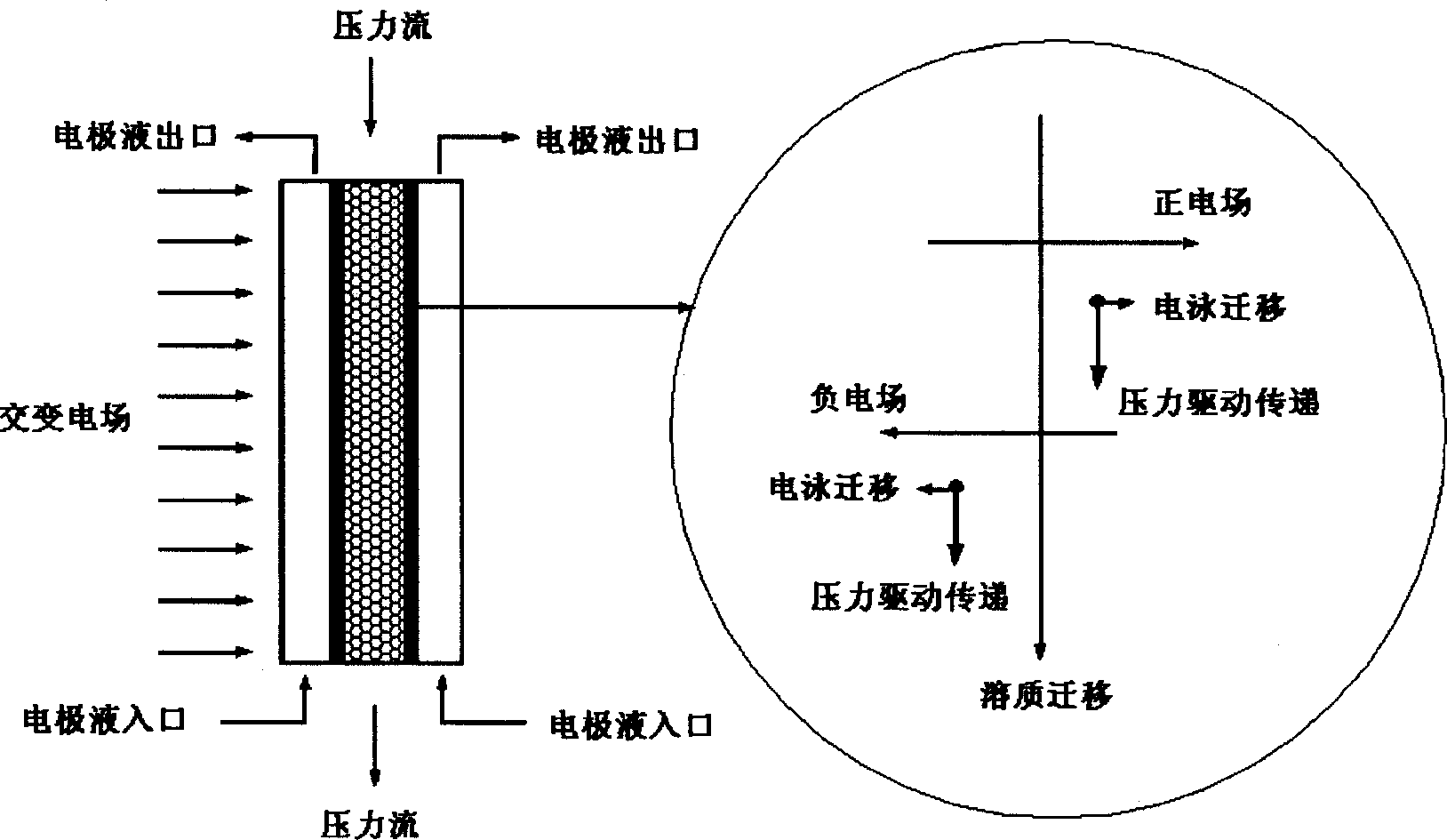

Method used

Image

Examples

Embodiment 1

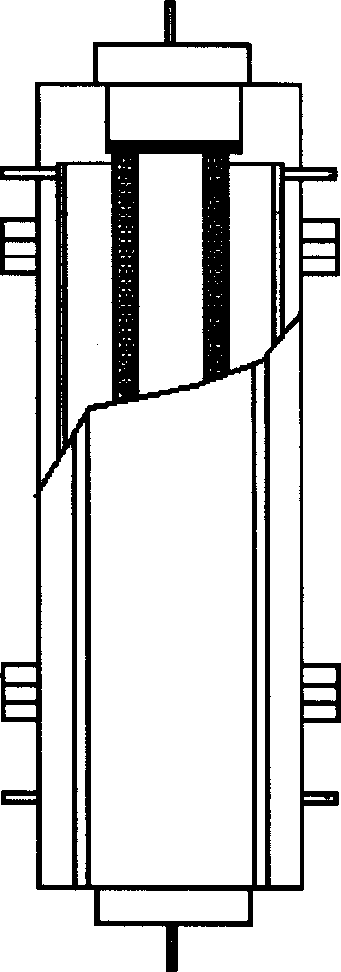

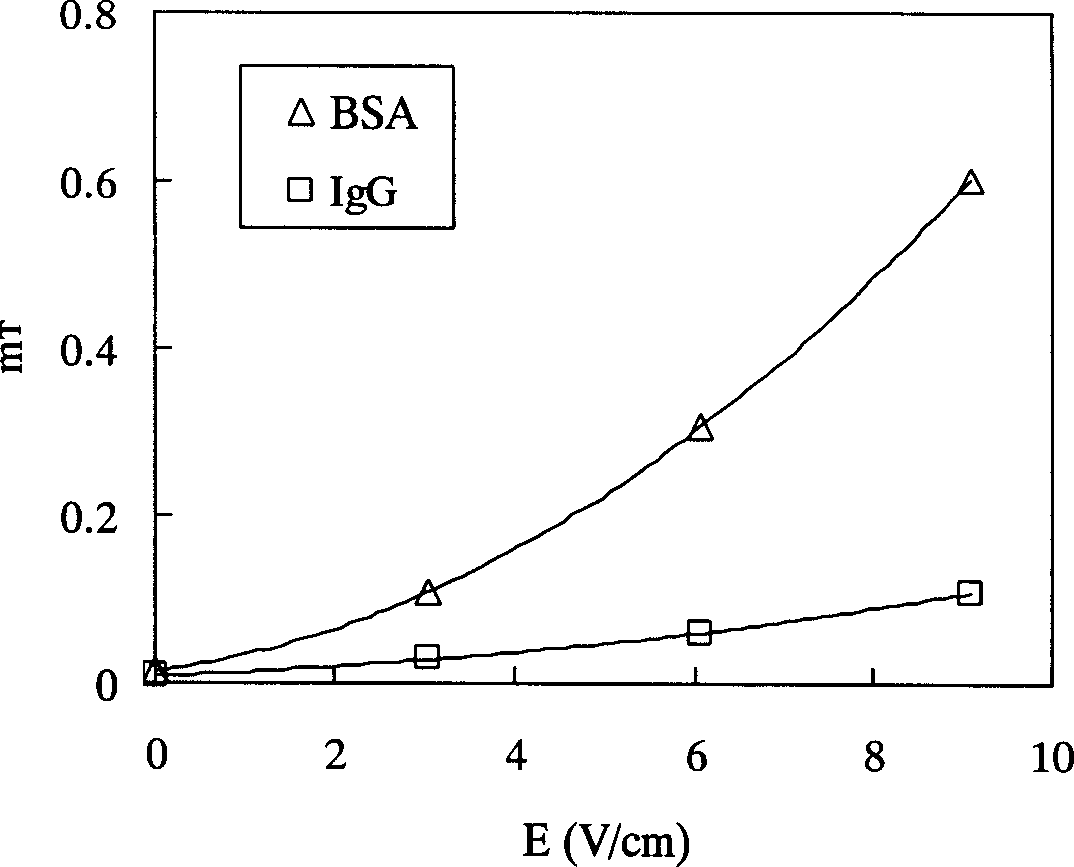

[0022] The size of the electrochromatographic gel chamber for separating bovine serum albumin and immunoglobulin G mixture is (length×width×depth) 20.0×0.5×1.2 cm, and the size of the electrode chamber is 20.1×0.8×0.8 cm. The mobile phase buffer was 3.9mmol / L Tris-47mmol / L Gly buffer (pH8.2) containing 5.0mmol / L sodium chloride. The protein mixture with a total concentration of 1.0mg / mL is prepared by mixing equal volumes of bovine serum albumin and immunoglobulin sample solutions with a concentration of 1.0mg / ml. All buffers were filtered through a 0.45 μm microporous membrane and degassed by ultrasonication for 15 minutes. After the gel chamber and the electrode chambers on both sides were equilibrated with buffer solution for 10 minutes, the Sephadex G-75 gel was filled into the gel chamber of the electrochromatographic column by gravity filling. Then, the medium in the gel chamber was equilibrated with the mobile phase buffer until the UV absorbance value (280 nm) reached...

Embodiment 2

[0024] The size of the electrochromatographic gel chamber for separating myoglobin and lysozyme mixture is (length×width×depth) 20.0×0.5×1.2 cm, and the size of the electrode chamber is 20.1×0.8×0.8 cm. The mobile phase buffer is 8.0mmol / L acetate buffer (pH4.9). A protein mixture with a total concentration of 1.0 mg / mL was prepared by mixing the same volume of the above single protein sample solutions. All buffers were filtered through a 0.45 μm microporous membrane and degassed by ultrasonication for 15 minutes. After the gel chamber and the electrode chambers on both sides were equilibrated with buffer solution for 10 minutes, the Sephadex G-75 gel was filled into the gel chamber of the electrochromatographic column by gravity filling. Then, the medium in the gel chamber was equilibrated with the mobile phase buffer until the UV absorbance value (280 nm) reached the baseline and stabilized around the baseline. The buffer flow rate was 0.2ml / min. On both sides of the gel ...

Embodiment 3

[0026] The size of the electrochromatographic gel chamber for separating bovine serum albumin and myoglobin mixture is (length×width×depth) 20.0×0.5×1.2 cm, and the size of the electrode chamber is 20.1×0.8×0.8 cm. The mobile phase buffer is 8.0mmol / L acetate buffer (pH4.9). A protein mixture with a total concentration of 1.0 mg / mL was prepared by mixing the same volume of the above single protein sample solutions. All buffers were filtered through a 0.45 μm microporous membrane and degassed by ultrasonication for 15 minutes. After the gel chamber and the electrode chambers on both sides were equilibrated with buffer solution for 10 minutes, the Sephadex G-75 gel was filled into the gel chamber of the electrochromatographic column by gravity filling. Then, the medium in the gel chamber was equilibrated with the mobile phase buffer until the UV absorbance value (280 nm) reached the baseline and stabilized around the baseline. The buffer flow rate was 0.2ml / min. On both sides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com