Preparation method of gas phase nano titanium dioxide with average grain size

A nano-titanium dioxide, gas-phase technology, applied in the direction of titanium dioxide, nanostructure manufacturing, titanium oxide/hydroxide, etc., can solve problems such as uneven temperature field and concentration field, uneven residence time distribution, and easy scarring at the nozzle outlet , to achieve the effect of overcoming uneven temperature field and concentration field, and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

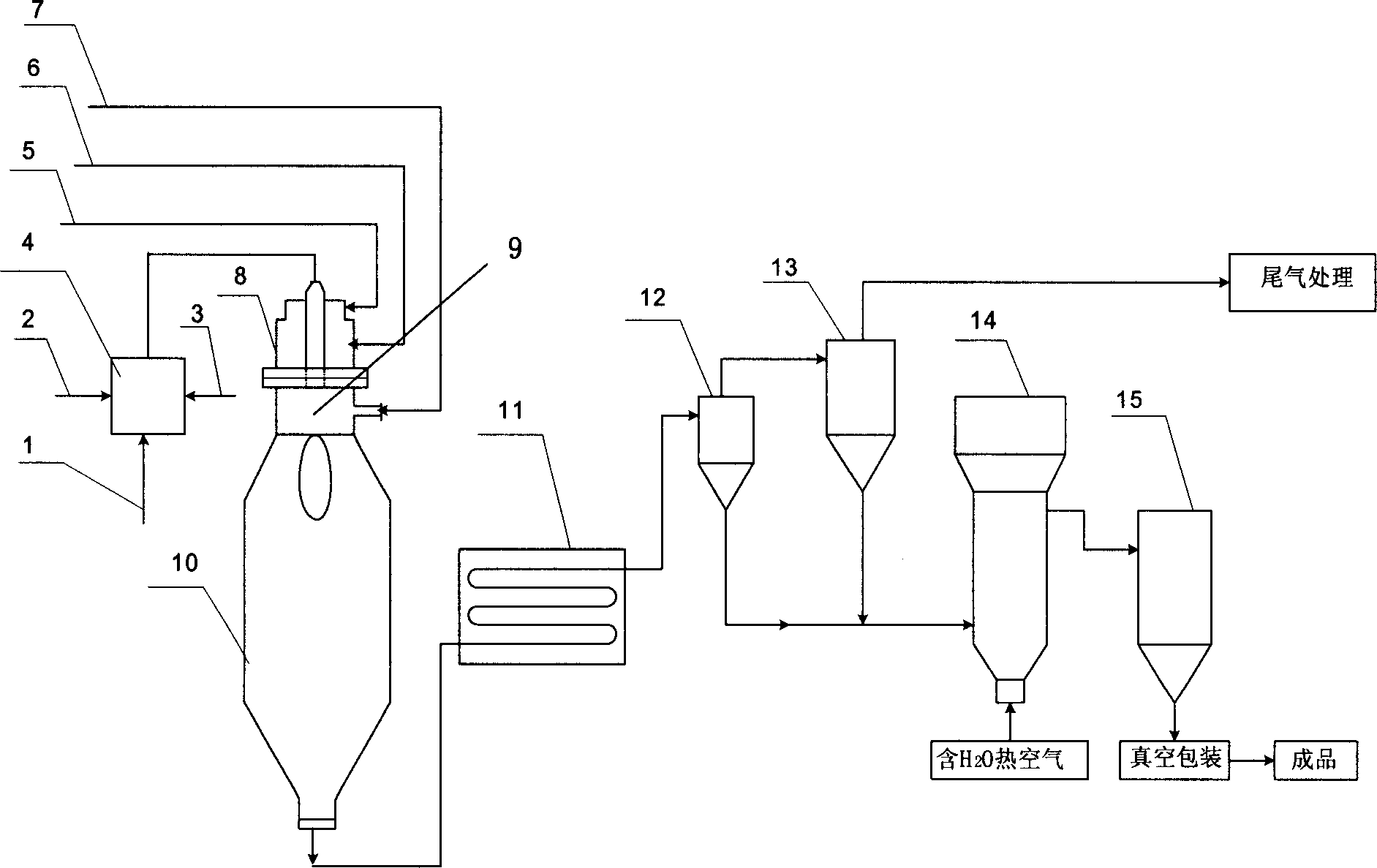

[0029] 12L / h liquid titanium tetrachloride is vaporized by electric heating, and its steam enters the mixer after being dried, purified and preheated, and at the same time there is another H 2 at 9.5m 3 / h and air at 30m 3 The / h gas is also passed into the mixer after being dried and purified. After the mixed gas is preheated to a certain temperature, it is introduced into the central tube of the reactor and ejected at a high speed. The total gas velocity at the outlet of the central tube is 85m / s. Another purified hydrogen is 9.8m 3 / h and air at 20m 3 / h mixed and passed into the second ring of the reactor, after being ignited and sprayed out at a high speed, the total gas velocity at the outlet of the second ring is 65m / s. The three rings of the reactor are at 40m 3 / h and the fourth ring at 100m 3 / h into the purified air to quench the reaction system, the gas velocity at the outlet of the third ring is 31m / s, and the gas velocity at the outlet of the fourth ring tang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com