Appearance controllable CeO2 precursor----- Ce2O(CO3)2 H2O powder preparation method

A precursor, the technology of ce2o, is applied in the fields of chemical instruments and methods, rare earth metal compounds, inorganic chemistry, etc., and can solve the problems of single particle shape, limiting the application and development of particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

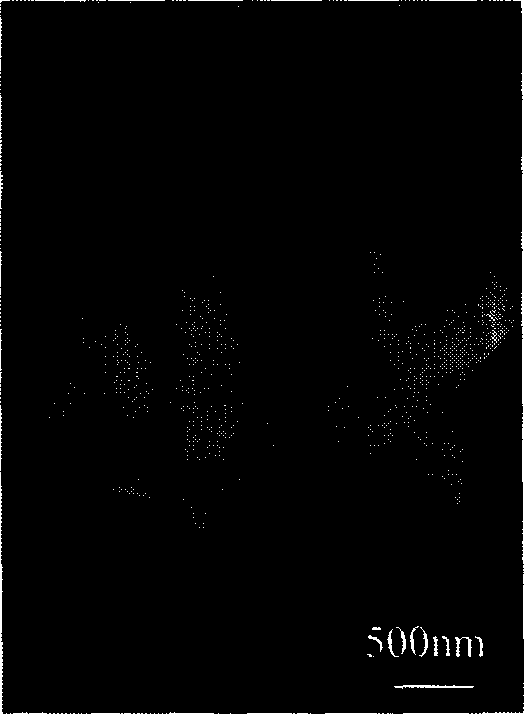

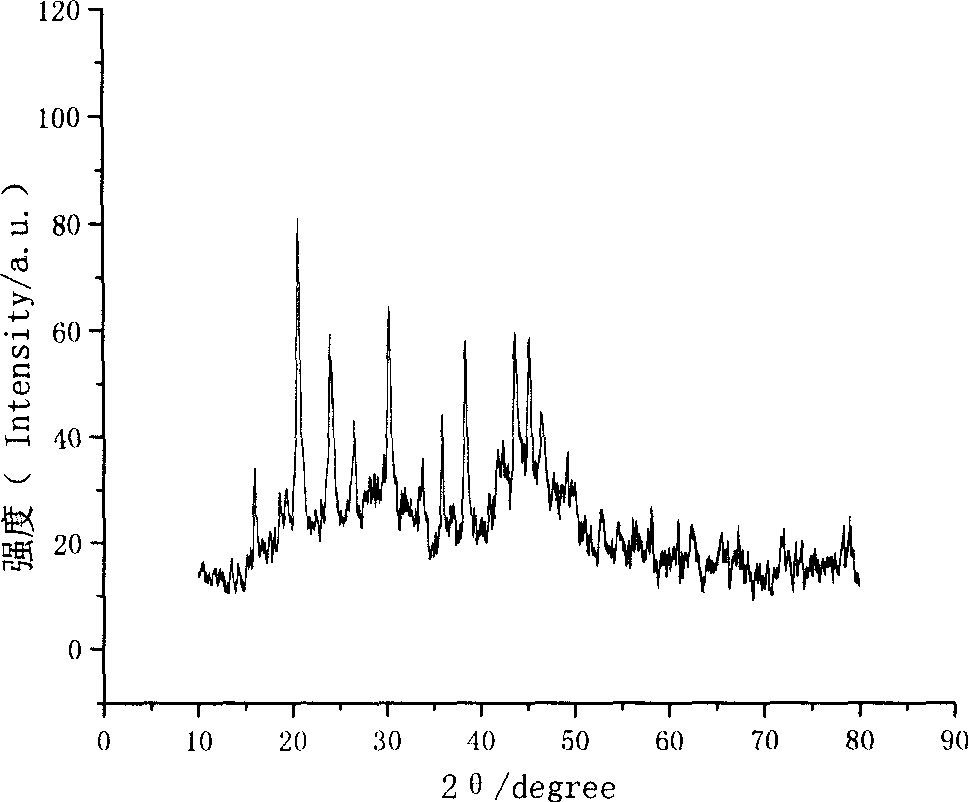

[0039] Example 1: Dissolving solid trivalent cerium salt in water to form 0.1mol L -1 solution, add urea to this solution to form Ce 3+ : The clarified mother liquor of urea=1:40. Add the cationic surfactant cetyltrimethylammonium bromide (CTAB) that is 0.5% by weight in this mother liquor, put the mixed solution into the constant temperature water bath of 80 ℃ and stir continuously for several hours, the reaction process produces abundant white foam. The precipitate was separated by centrifugation, washed with deionized water and then with ethanol. The precipitate was dried at room temperature to obtain a shuttle-like Ce with uniform morphology 2 O(CO 3 ) 2 ·H 2 O white powder, XRD confirmed that its degree of crystallization is strong.

example 2

[0040] Example 2: Dissolving solid trivalent cerium salt in water to form 0.2mol L -1 solution, add urea to this solution to form Ce 3+ : The clarified mother liquor of urea=1:50. Add 0.7% by weight cationic surfactant diisooctyl sodium sulfosuccinate (A-OT) to this mother liquor, and put the mixed solution in a constant temperature water bath at 90°C for continuous stirring for several hours, and there is no foam in the reaction process produce. The precipitate was separated by centrifugation, washed with deionized water and then with ethanol. The precipitate is dried at room temperature, and the Ce with a relatively uniform shape is obtained. 2 O(CO 3 ) 2 ·H 2 O white powder, XRD confirms that its degree of crystallization is relatively strong.

example 3

[0041] Example 3: Dissolving solid trivalent cerium salt in water to make 0.1mol L -1 solution, add urea to this solution to form Ce 3+ : The clarified mother liquor of urea=1:25. Add 0.7% by weight non-ionic surfactant polyethylene glycol 19000 (PEG19000) to this mother liquor, and put the mixed liquor into a constant temperature water bath at 85° C. and stir continuously for several hours without abundant foam during the reaction. The precipitate was separated by centrifugation, and the precipitate was washed with dewatered water and then with ethanol. The precipitate is dried at room temperature, and the well-arranged and highly ordered Ce 2 O(CO 3 ) 2 ·H 2 O rod-shaped powder, XRD confirmed that its degree of crystallization is strong.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com