Catalyst for degrading water organic pollutant by microwave

A technology of organic pollutants and microwave degradation, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, magnetic field/electric field water/sewage treatment, etc., can solve problems such as energy waste and achieve catalytic The effect of high activity, improved wave absorption performance and catalytic degradation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Accurately dissolve 0.05 mole of citric acid in 50ml of deionized water. After the citric acid is dissolved, slowly add 0.002 mole of barium nitrate and 0.02 mole of ferric nitrate while stirring. It fully undergoes a coordination reaction with citric acid, then adds 0.2 moles of ethylene glycol, and heats at 130°C for 2 hours to promote the esterification reaction of citric acid and ethylene glycol to form a gel polymer. The gel polymer is placed in a vacuum state, the heating rate is 2-5°C / min, the temperature is raised to 300°C, and the holding time is 2-5 hours, and the powdery precursor is generated by pyrolysis; then heat treatment is carried out at 800°C, A foam material composited with barium ferrite and pyrolytic carbon was obtained, and catalyst 1 of the present invention was obtained.

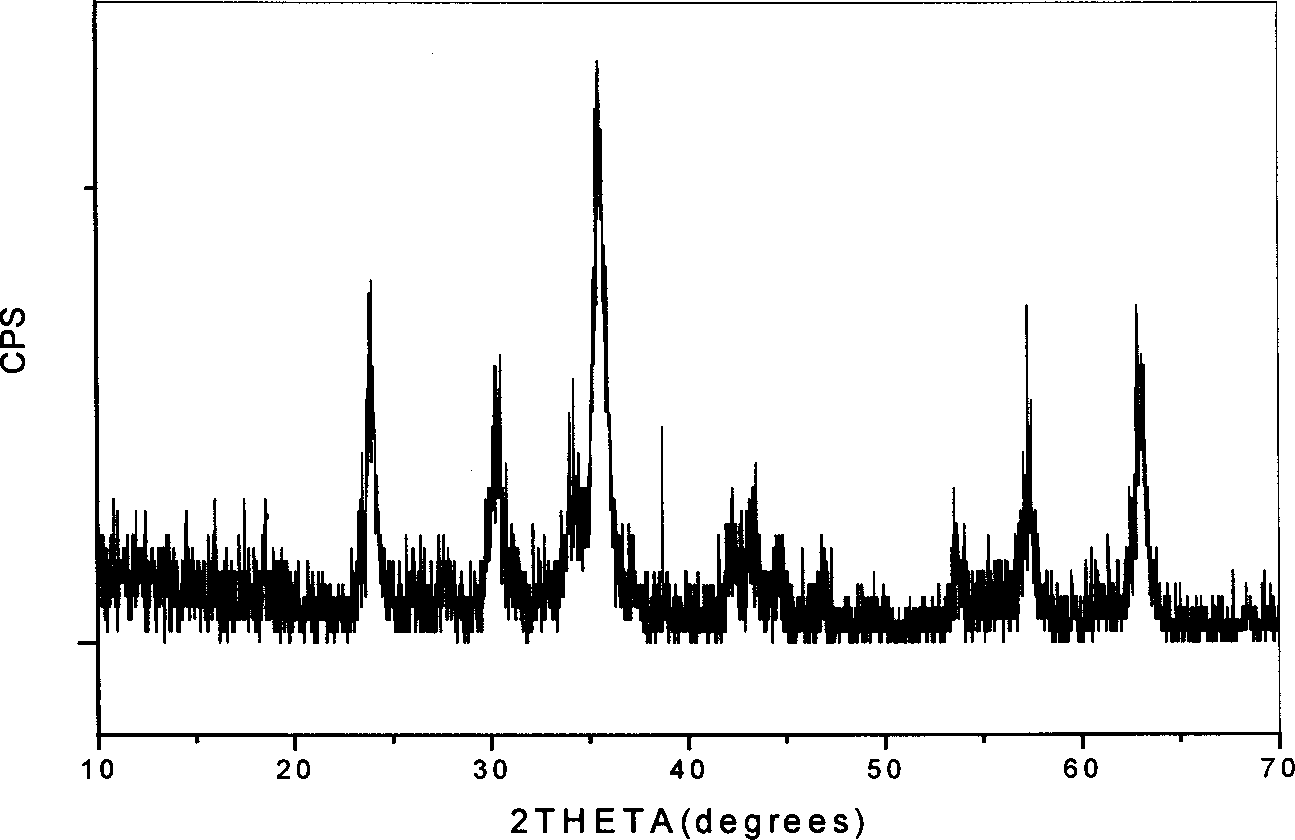

[0030] The barium ferrite X-ray diffraction spectrogram obtained above is shown in figure 1 . Depend on figure 1 It can be seen that in the XRD pattern of the sample, there...

Embodiment 2

[0033] Accurately dissolve 0.06 mole of citric acid in 50ml of deionized water. After the citric acid is dissolved, slowly add 0.002 mole of barium nitrate and 0.028 mole of ferric nitrate while stirring, and at the same time add 0.01 mole of nickel oxide with an average particle size of 1.0 μm. The temperature is controlled at Between 40°C and 70°C, continue heating for 5 hours to make it fully coordinate with citric acid, then add 0.24 moles of ethylene glycol, and heat at 140°C for 2 hours to promote esterification of citric acid and ethylene glycol reaction to form a gel polymer, which is pyrolyzed at 400°C under the protection of nitrogen to form a powder precursor, and then heat-treated at 900°C to obtain a composite of barium ferrite and pyrolytic carbon The foamed material obtained catalyst 2 of the present invention.

Embodiment 3

[0035]Accurately dissolve 0.04 mole of citric acid in 50ml of deionized water. After the citric acid is dissolved, slowly add 0.002 mole of barium nitrate and 0.024 mole of ferric nitrate while stirring, and at the same time add 0.05 mole of SiC with an average particle size of 50 μm and 0.001 mole of cobalt sulfate , the temperature is controlled between 70°C and 90°C, and the heating is continued for 3 hours to make it fully coordinate with citric acid, then add 0.16 moles of ethylene glycol, and heat at 130°C for 2 hours to promote citric acid and ethylene glycol Alcohol undergoes an esterification reaction to form a polymer. In a vacuum state, the polymer is pyrolyzed at 300°C to form a powder precursor, and then heat-treated at 700°C to obtain a composite of barium ferrite and pyrolytic carbon. The foamed material obtained catalyst 3 of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com