Humic acid biological fertilizer and its production method

A humic acid and bio-fertilizer technology, applied in organic fertilizers, fertilization devices, fertilizer mixtures, etc., can solve problems such as inability to coordinate water, fertilizer, air, and heat conditions, soil without aggregate structure, and yellowing of plant leaves, etc., to achieve Raw materials are easy to obtain, improve soil fertility, and shorten the process flow

Inactive Publication Date: 2006-05-03

刘甫名 +1

View PDF2 Cites 32 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

But the existing humic acid compound fertilizer not only does not have the good effect of bacterial fertilizer, but also adds a large amount of urea (15-25%) in the formula, so that the organic matter in the soil decreases gradually, and the base substances such as calcium and magnesium are deficient. As a result, the soil is acidified and compacted, the soil has no aggregate structure, and the conditions of water, fertilizer, air, and heat in the soil cannot be coordinated, and the high-concentration ammonia poisoning produced by the high-concentration urea in the hydrolysis process causes the leaves to turn yellow and chlorosis. The nitrogen loss caused by rainwater washing also causes water pollution

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

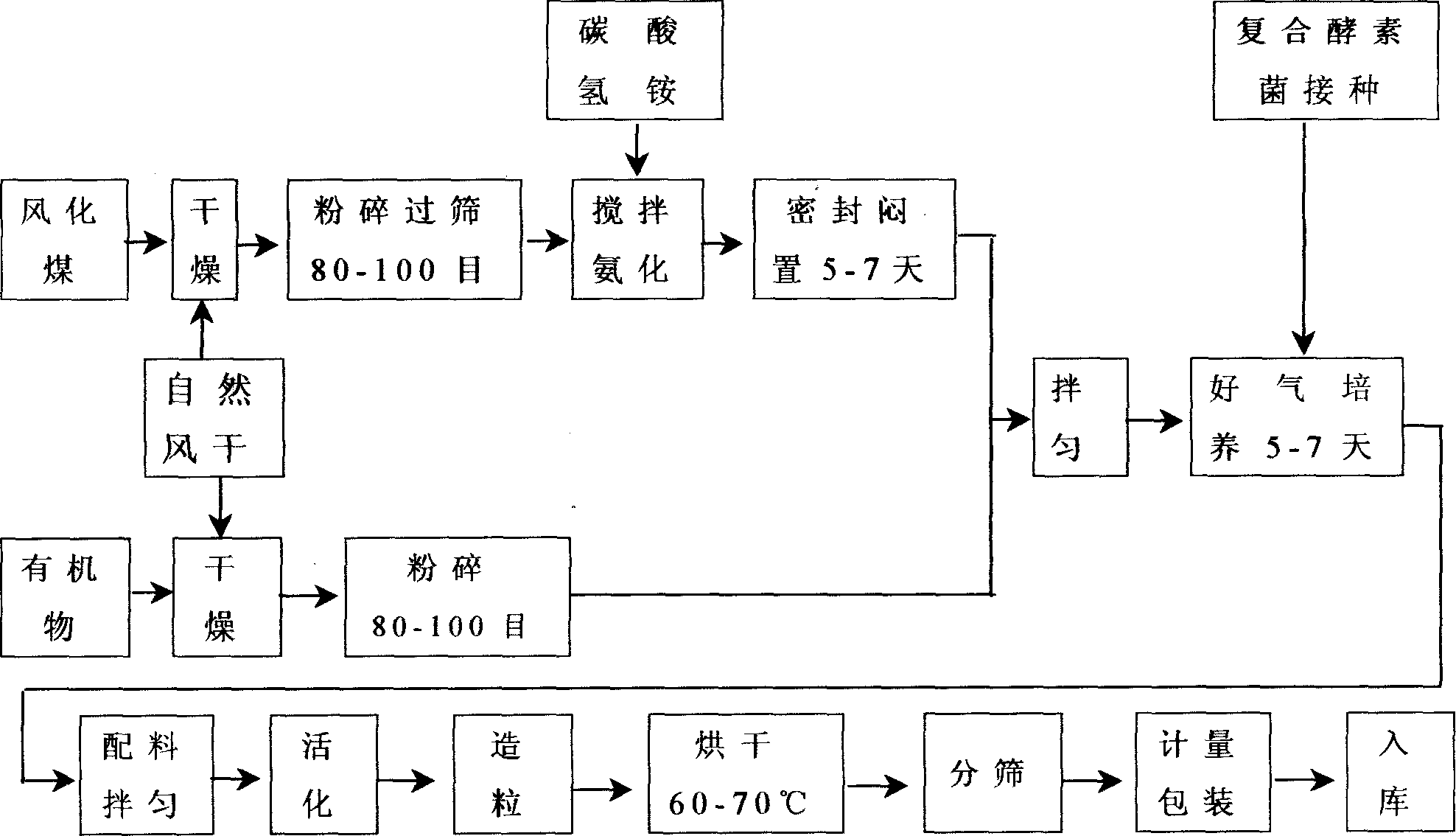

[0023] Embodiment: get humic acid fermented fertilizer 75%, heavy calcium 6%, potassium hydride 7%, trace element boron fertilizer (or zinc or molybdenum fertilizer) 2% by weight percentage, urea 10% is placed in the stirrer and stirs evenly, activates 15 - Granulate in 20 minutes, dry at 60-70°C, sieve, measure, pack, and put into storage to obtain humic acid bio-fertilizer whose quality meets the technical standards of the enterprise.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention produces a new humic acid bio-fertilizer, which comprises: using weathered coal and good organic (such as maize-ear and domestic animal manure) as main material with mineral phosphorus, potash fertilizer, chemical nitrogen fertiliser and microelement; ammonifying the wethered coal with size less than 80 items to mix with organic; accessing composite ferment fungus for solid fermentation to cut process and time. This invention reduces cost, overcomes shortcomings of high-nitrogen formula fertilizer, and has spread value.

Description

1. Technical field: [0001] The invention belongs to the technical field of a new type of environmentally friendly humic acid biofertilizer manufactured by fermenting and activating organic ore humic acid (weathered coal, lignite, peat), mineral phosphorus, potassium, trace element fertilizer, nitrogen fertilizer, and biological preparations in the chemical fertilizer industry. 2. Background technology: [0002] Fertilization of cultivated land in most parts of my country is unreasonable, especially the application of organic fertilizers has been severely reduced. With the development of the chemical fertilizer industry, the application of chemical fertilizers has risen sharply, and a large amount of inorganic chemical fertilizers N, P, and K fertilizers not only have low fertilizer utilization rates and high costs, but also lead to soil acidification and compaction, salinization, and nutrient imbalances, and crop yields have been hovering for a long time In the middle and lo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C05G1/00C05F11/02C05F11/08C05G3/00

Inventor 秦正惠

Owner 刘甫名

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com