Liquid phase chemical reaction method for preparing basic magnesium chloride

A technology of liquid-phase chemical reaction and liquid-phase reaction, which is applied in the field of preparation of one-dimensional nanomaterials, can solve the problems of restricting large-scale production and application, high reaction temperature and high preparation cost of gas-phase method, and achieves good single crystal crystallization performance and easy process Control, effect of shape rules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

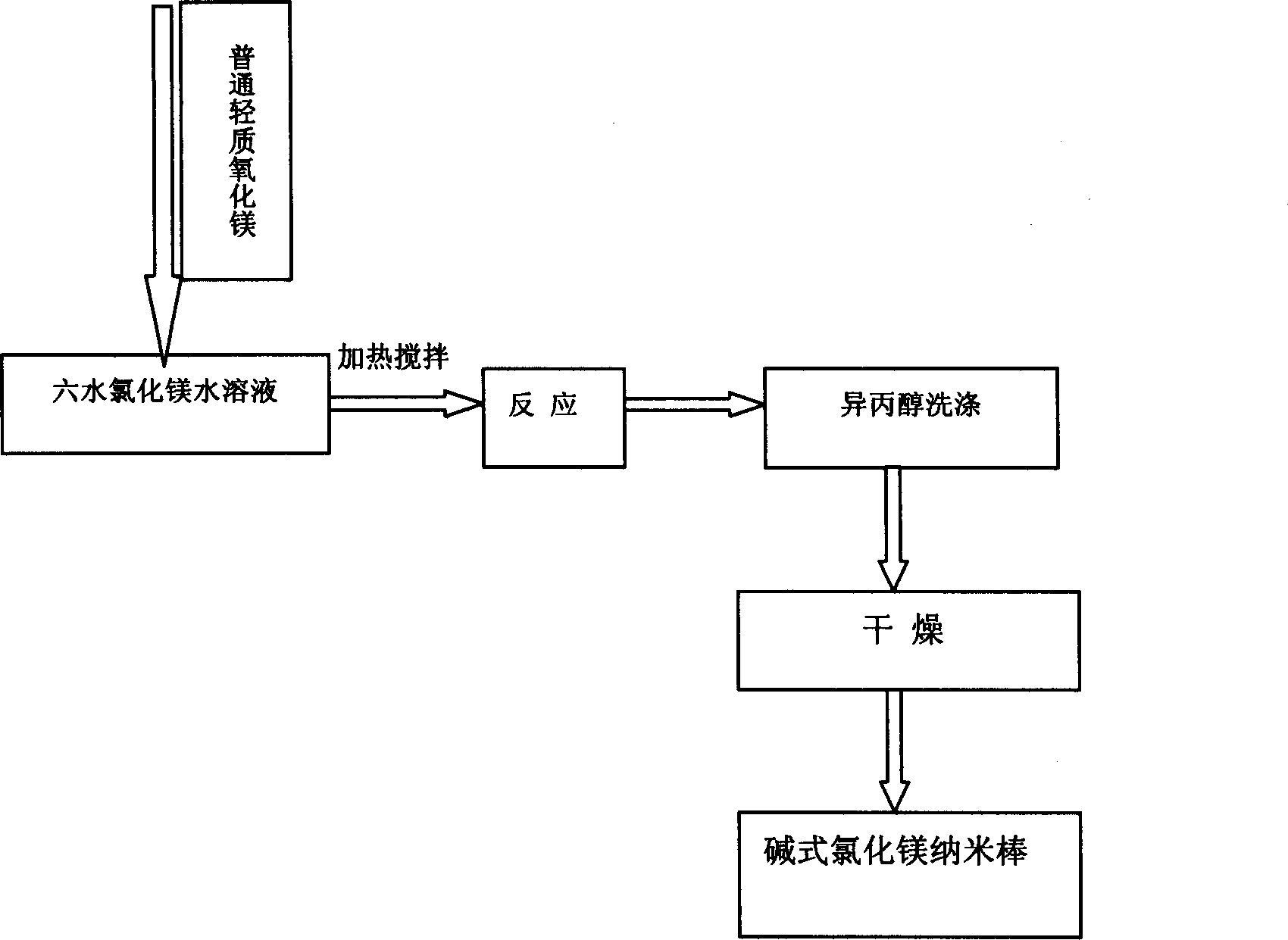

[0018] (1) At first, magnesium chloride hexahydrate is prepared into an aqueous solution of 6 mol / l, according to MgCl 2 The molar ratio of / MgO is 1:30. The ordinary light magnesium oxide is added to the aqueous solution of magnesium chloride hexahydrate, and the water bath is heated to 340K, and the stirring speed is 600r / min. After 12 hours of reaction, vacuum extraction;

[0019] (2) washing the filtered gel state precipitate with deionized water 5 times;

[0020] (3) 1 gram of precipitation was washed 4 times with 30 milliliters of isopropanol;

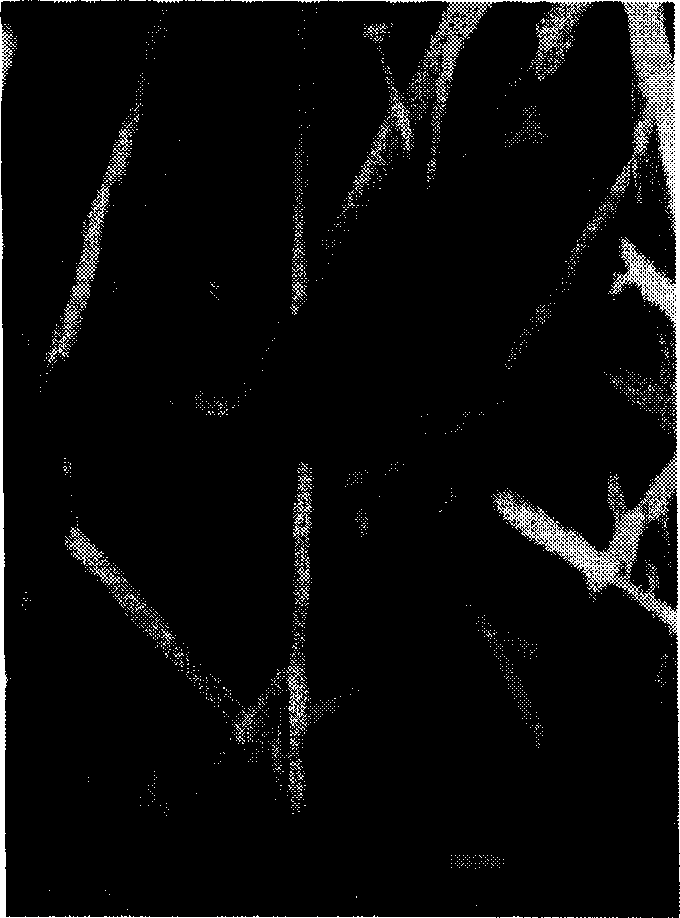

[0021] (4) drying the washed precipitate at 360K for 7 hours to obtain basic magnesium chloride nanorod crystals with a diameter of about 100-200 nm and a length of about 4-8 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com