Method for preparing thin film material of metal zirconium

A thin film material, metal zirconium technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problem of reducing the internal stress of metal zirconium thin film film, increasing contact resistance, affecting the quality of film growth, etc. problems, to achieve the effect of high-purity growth and reduction of raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

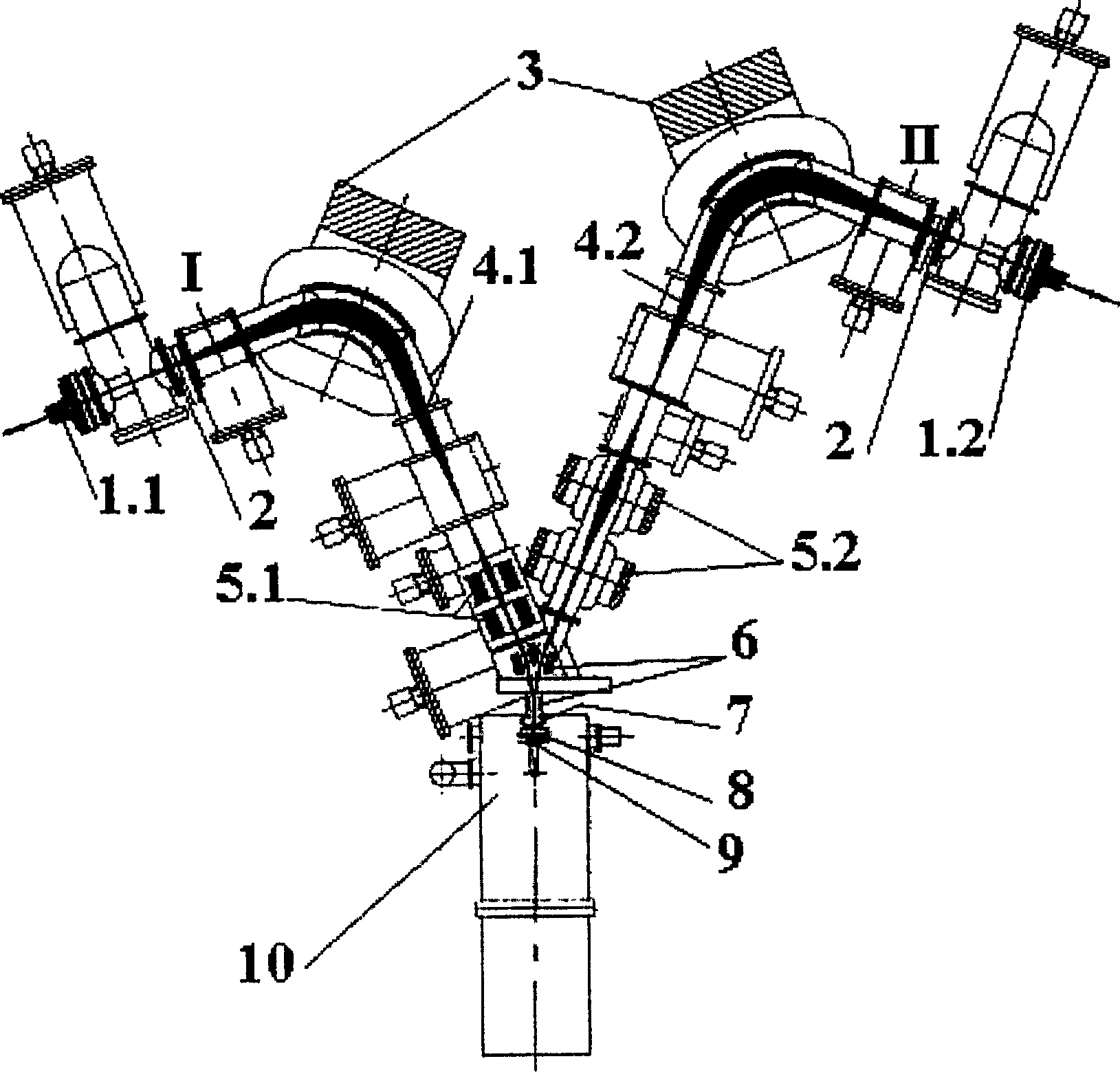

Method used

Image

Examples

Embodiment

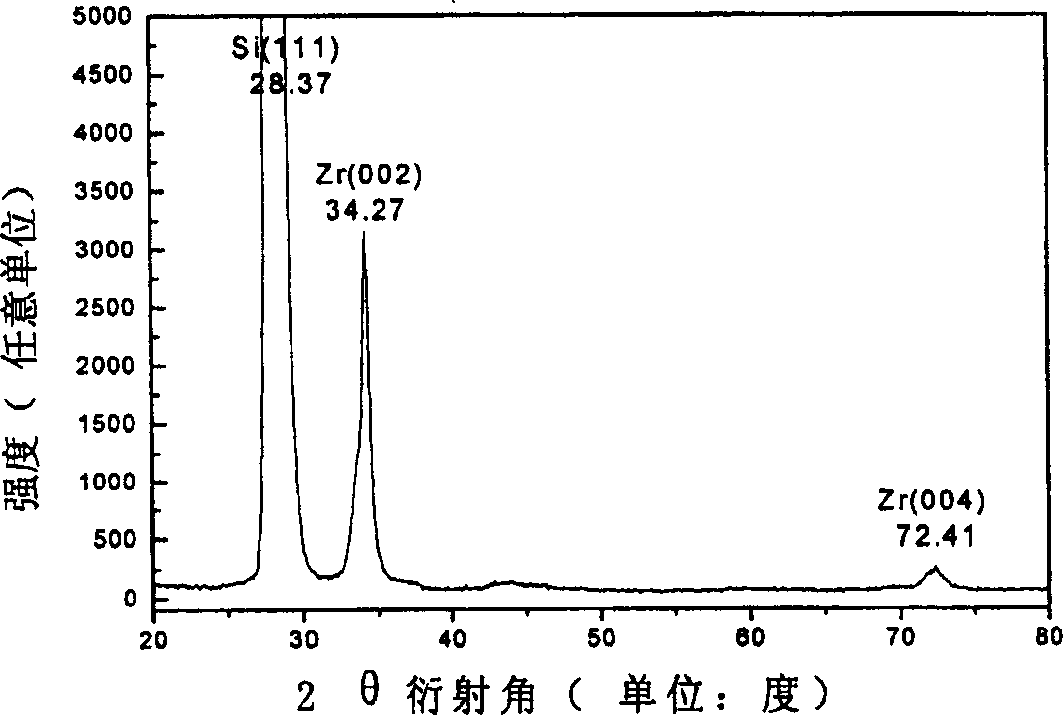

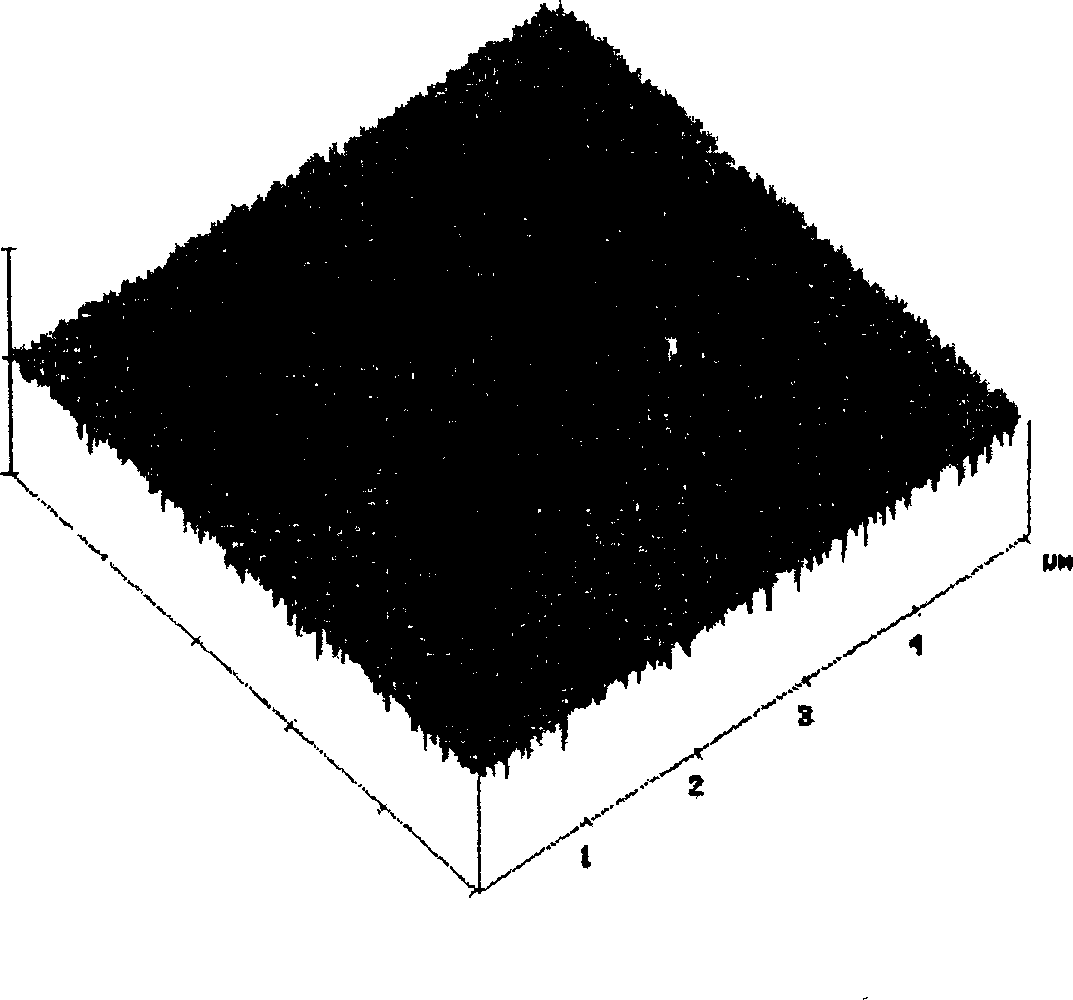

[0095] Concrete embodiment sees the relevant experimental data of table 1 and figure 2 , 3 , 4 experimental results.

[0096] Table 1: Experimental parameters and results of metal zirconium thin film materials prepared on silicon Si substrates using ion beam epitaxy (IBE) growth equipment.

[0097]

[0098]

[0099] V 离子束加速电压

15KV

15KV

15KV

V 磁分析器测谱电压

362.2mV

211.4mV

529.4mV

I 分析器后法拉第筒束流

3mA

2mA

0.1mA

V I束电四极透镜纵向电压

1.8KV

V I束电四极透镜横向电压

1.5KV

V II束磁四极透镜纵向电压

413mV

218mV

V II束磁四极透镜横向电压

341mV

181mV

V 静电偏转电极(正负)电压

1.7KV

1.6KV

1.6KV

V 减速透镜电压

300V

200V

200V

I 靶面束流

400μA

300μA

30μA

Argon ions (Ar + ) beam dry cleani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com