Method for fabricating transistor of single electron based on Nano carbon tubes

A technology of single-electron transistors and carbon nanotubes, applied in nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve problems such as reducing tunnel junction capacitance and reducing electrode size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

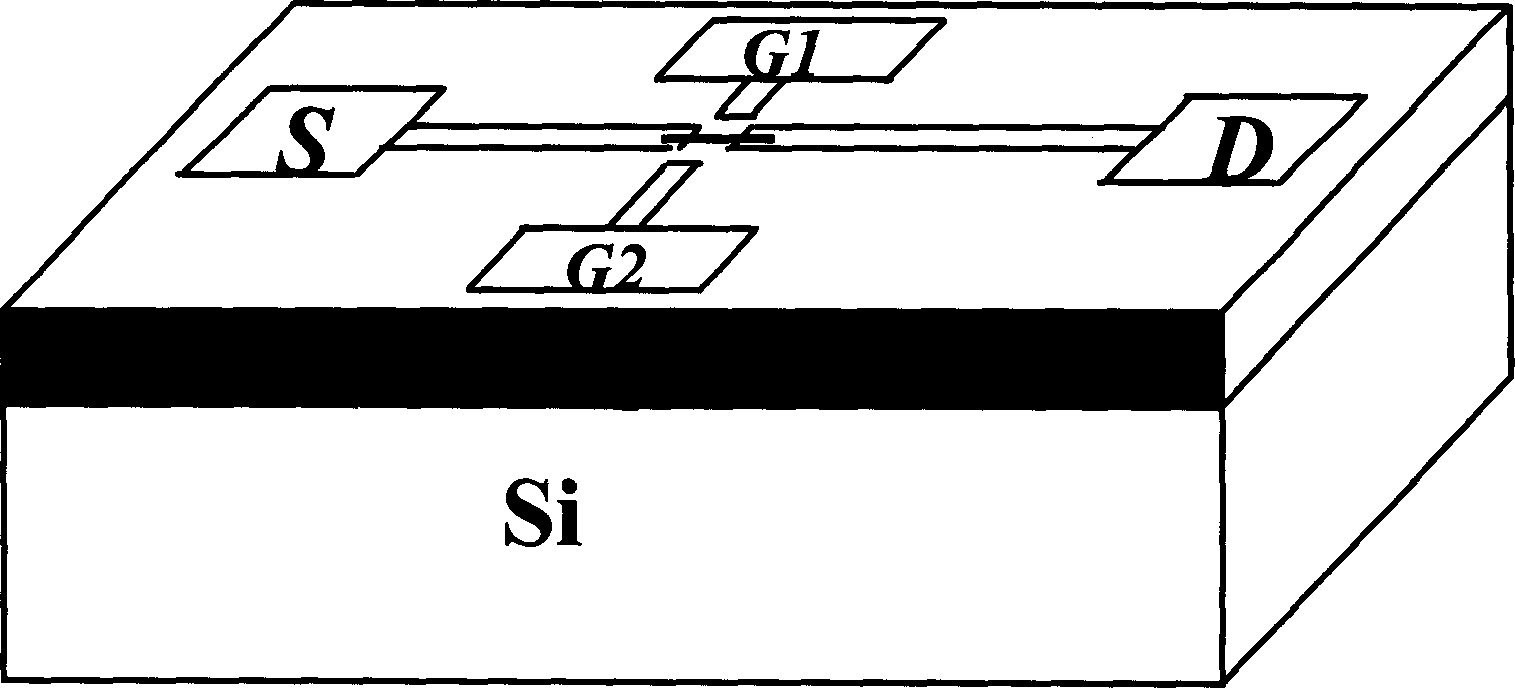

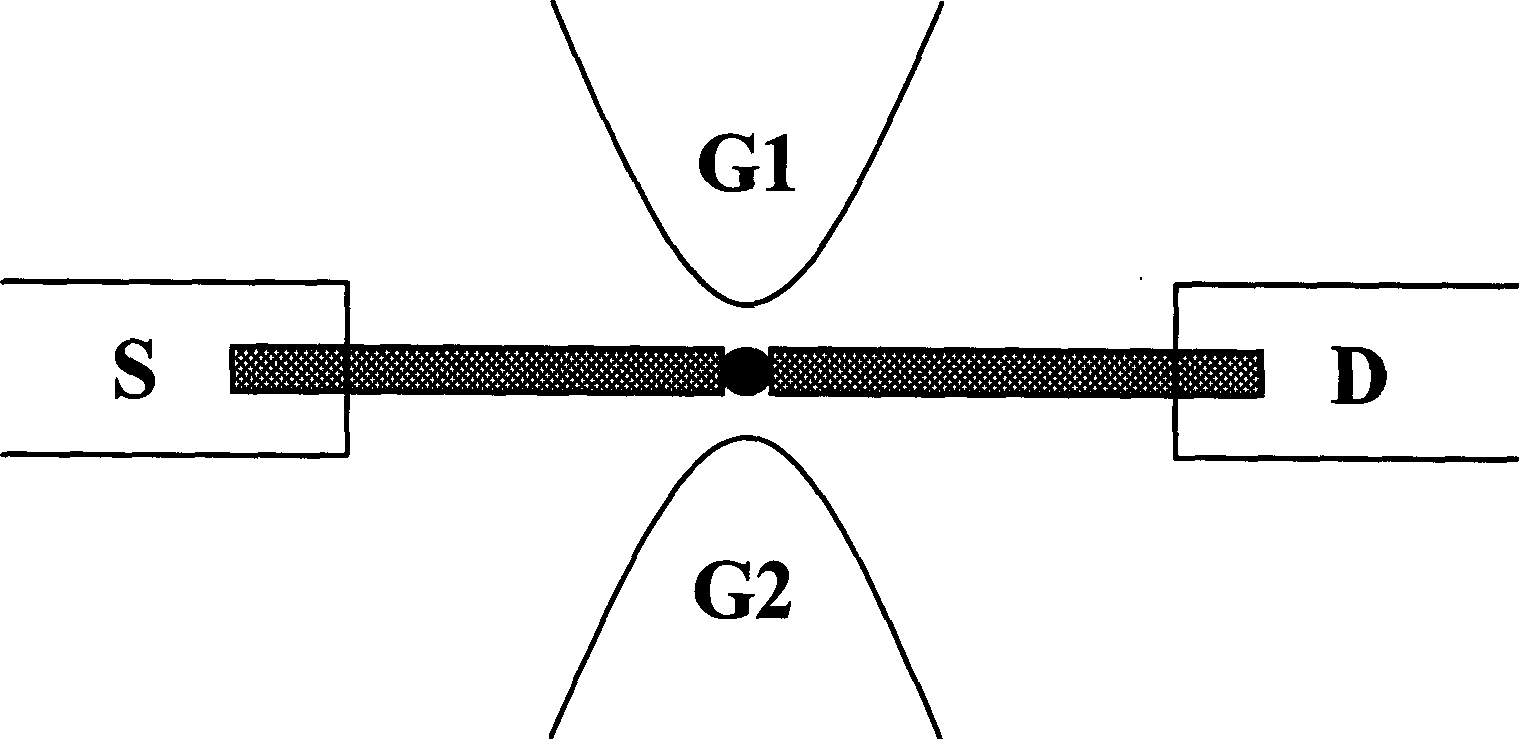

[0021] 1. Electrode design and preparation

[0022] In order to prepare nano-electrode pairs of carbon nanotubes (or tube bundles), first design micron-scale metal electrodes, the electrode shape is cross-shaped, the design width is 2 μm, the distance between opposite electrodes is 2 μm, and the distance between adjacent electrodes is 200-500nm. On the P-type heavily doped silicon substrate, silicon dioxide with a thickness of 180-300nm is thermally oxidized and grown as an insulating layer, and the metal electrode is prepared by photolithography and lift-off process. The process is: photolithography, exposure, and development; Then, the metal is deposited by sputtering, and the glue is removed to obtain a metal electrode. The electrode material is Ti / Au (10nm / 100nm). The schematic diagram of metal electrode and single electron device structure is attached figure 1 shown.

[0023] 2. Lap carbon nanotubes (or tube bundles) on metal electrodes

[0024] A pair of opposite elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com