Nanometer hydroxyapatite/chitosan/gelatin porous scaffold material and preparation method thereof

A technology of nano-hydroxyapatite and porous scaffold, which is applied in medical science, prosthesis, coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

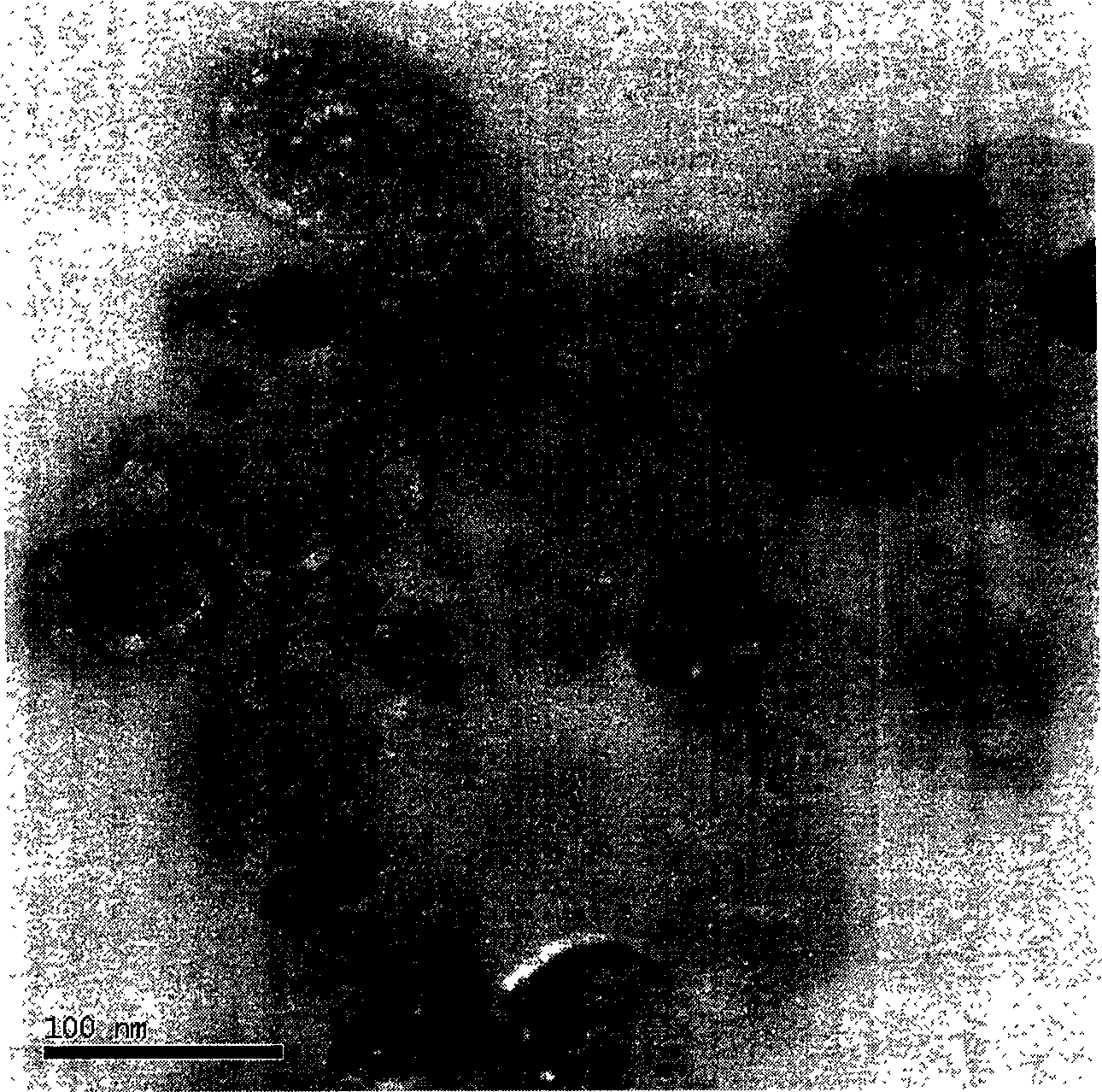

Image

Examples

Embodiment 1

[0021] (1) Prepare 50ml of acetic acid solution with a mass percentage concentration of 1%, weigh 1g of chitosan and dissolve it into it with magnetic stirring for 20min to fully dissolve it, and prepare a 2% chitosan solution with a mass concentration.

[0022] (2) Weigh 1 g of gelatin and dissolve it in 25 ml of deionized water at 50° C. to prepare a 4% gelatin solution.

[0023] (3) The two solutions of (1) and (2) were mixed, and magnetically stirred at room temperature for 10 hours.

[0024] (4) Prepare 100ml of 0.25% glutaraldehyde solution, take (3) 7ml of the prepared mixed solution and add 3ml of glutaraldehyde solution to the mixed solution, stir it magnetically for about 50s, and quickly drop it into the 24-well culture plate with a rubber dropper . Stand at 4°C for 12 hours to remove air bubbles in the solution. Then put the culture plate into a low-temperature refrigerator (-60°C) to pre-freeze for 12 hours.

[0025] (5) Place the pre-frozen gel in a freeze dry...

Embodiment 2

[0031] The raw materials used are the same as in the examples.

[0032] Embodiment one (8) is adjusted to take by weighing 2.36gCa (NO 3 ) 2 6H 2 O and 2.28gNa 3 PO 4 12H 2 O was dissolved in 100ml Tris biological buffer respectively (the Ca(NO 3 ) 2 solution and 0.06mol / L Na 3 PO 4 solution); chitosan / gelatin porous scaffold material in Ca(NO 3 ) 2 After soaking in the Tris biological buffer solution for 10 hours, wash it with deionized water for 2-3 times; then soak it in Na 3 PO 4 Tris biological buffer and adjust the pH value of the solution to between 11-13 with NaOH, take it out after 10 hours and rinse it with deionized water for 2-3 times; freeze-dry again.

[0033] The remaining steps are the same as in Embodiment 1.

Embodiment 3

[0035] The raw materials used are the same as the examples

[0036] Adjust the volume ratio of the chitosan / gelatin mixed solution and the glutaraldehyde solution in Implementation 1 (4) to 1:1, that is, take 5ml of the mixed solution and 5ml of the glutaraldehyde solution, mix them with magnetic force for about 40s and quickly use the glue head pipette to drop it into the 24-well plate.

[0037] The remaining steps are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com