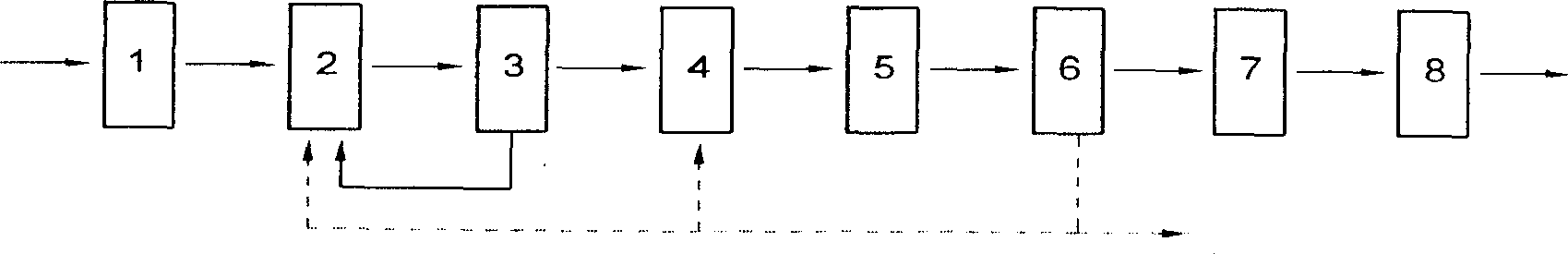

Waste water treatment method of anerobic- anoxia-aerobic-coagulated precipitation

A technology of coagulation sedimentation and wastewater treatment, which is applied in the direction of flocculation/sedimentation water/sewage treatment, textile industry wastewater treatment, aerobic and anaerobic process treatment, etc., and can solve problems such as not considering the influence of anaerobic treatment components and structures , to achieve the effects of reducing operating costs and investment costs, reducing sludge production, and improving biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0026] Example: A centralized sewage treatment plant in a textile printing and dyeing industrial zone, with a design scale of 30,000m 3 / d, using internal and external cycle anaerobic-anoxic-aerobic-coagulation sedimentation process, sewage treatment engineering design influent water quality: COD900~2000mg / l, BOD 5 250~600mg / l, pH 9~11, chroma 400 times, SS300mg / l. The total investment is 50 million yuan, and the operating cost is 1.45 yuan / m 3 , effluent COD60mg / l, BOD 5 10mg / l, pH7, chroma 40 times, SS15mg / l.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com