High purity cationic monomer diallyldimethylammonium Chloride refining method

A technology of dimethyl diallyl ammonium chloride and cationic monomer, which is applied in the purification/separation of amino compounds, organic chemistry, etc., can solve the problem of low volatility and water solubility, lack of theoretical guidance analysis method support, and difficulty in obtaining high purity and quality stable cationic monomer DMDAAC products and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

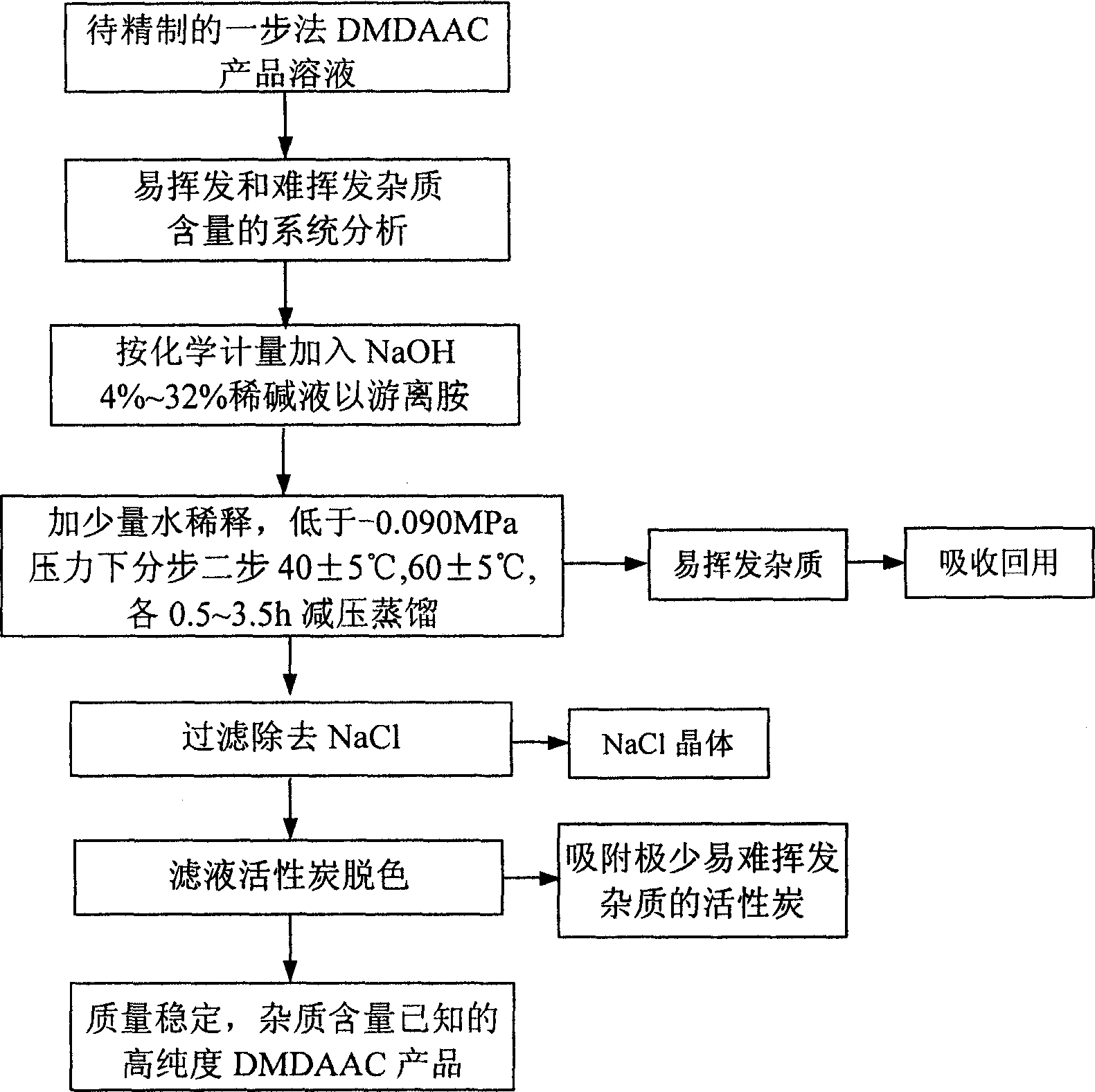

[0044] In conjunction with accompanying drawing, the concrete of the refining method of high-purity cationic monomer dimethyl diallyl ammonium chloride of the present invention

Embodiment approach

[0046] In the first step, the composition and content of various impurities in the cationic monomer DMDAAC aqueous solution to be refined made by the one-step process are systematically analyzed by chromatographic analysis method, and the contained volatile and difficult volatile impurities are respectively dimethylamine, The corresponding contents of allyl chloride, allyl alcohol, allyl aldehyde and sodium chloride, dimethylamine hydrochloride and tertiary amine hydrochloride are shown in Table 2.

[0047] In the second step, in a 120L still or a 200L falling film evaporator, adding the content to be refined is 60% one-step monomer DMDAAC solution A 50kg, and the amine hydrochloride (dimethylamine hydrochloride) obtained according to chromatographic analysis salt, tertiary amine hydrochloride) is 0.87 (7.66mol), according to the ratio of the amount of amine hydrochloride: sodium hydroxide is 1.00: 1.00 ~ 0.99, adding the content under cooling and stirring is 8.0% 3.79kg (7.58...

Embodiment 2

[0053] In conjunction with accompanying drawing, the embodiment of the refining method of high-purity cationic monomer dimethyl diallyl ammonium chloride of the present invention is:

[0054] The first step is to systematically analyze various impurity components and contents in the cationic monomer DMDAAC aqueous solution B to be refined prepared by the one-step process with the chromatographic analysis method, and the contained volatile and difficult volatile impurities are respectively: dimethyl Amine, allyl chloride, allyl alcohol, allyl aldehyde and sodium chloride, dimethylamine hydrochloride, tertiary amine hydrochloride, the contents are shown in Table 3 below.

[0055] In the second step, in a 120L still or a 200L falling film evaporator, adding the content to be refined is 65% one-step monomer DMDAAC solution B 50kg, and the hydrochloride (dimethylamine salt) of the amines obtained according to chromatographic analysis salt, tertiary amine hydrochloride) is 1.35kg (1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com