Precipitation method and device for plasma reinforced film

A thin film deposition device and plasma technology, which are applied in ion implantation plating, coating, electrical components, etc., can solve the problems of limited source of raw materials, difficulty in applying refractory metals, etc., to improve the quality of thin film products, widely applicable to raw materials, Increase the effect of atomic energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The implementation of the present invention will be described below with specific examples.

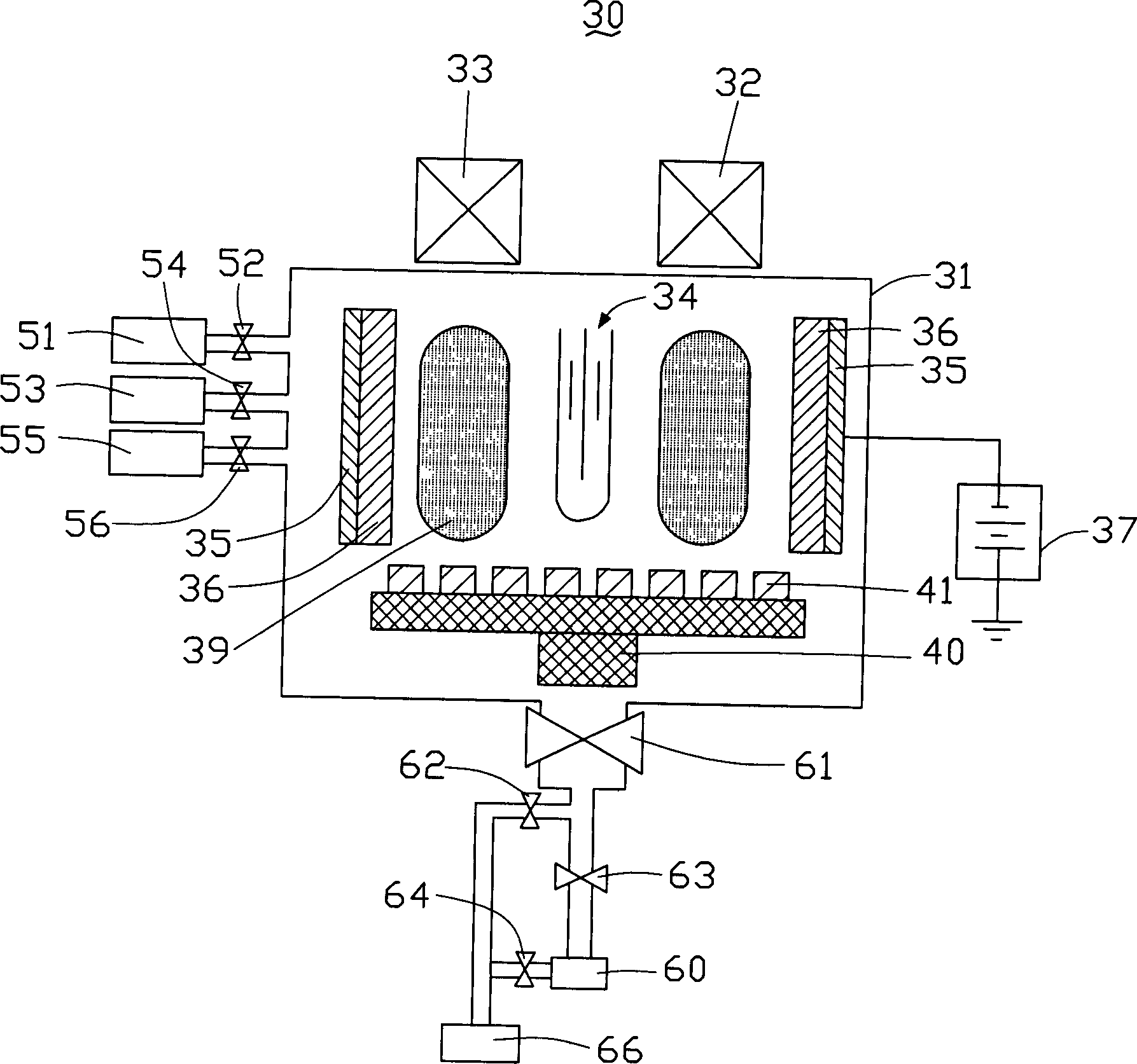

[0027] see figure 2 , the plasma-enhanced thin film deposition device 30 of the embodiment of the present invention mainly includes: a reaction chamber 31, which is a closed cavity body, and a vent (not shown) is opened on one side of the reaction chamber 31, and three gas Sources 51, 53 and 55 are respectively connected to the vent and communicated with the reaction chamber through flow controllers 52, 54 and 56; wherein, the gas source 51 can provide argon (Ar), krypton (Kr) or Xenon (Xe); gas source 53 can provide a mixed gas of argon and nitrogen (N2); gas source 55 can provide argon and hydrogen (H2), argon and methane (CH4) or argon and ethane (C2H6) of mixed gas. The switch and flow of the reaction gas can be controlled by a flow controller.

[0028] A pair of magnetic coils 32 and 33 are arranged on the top attachment outside the reaction chamber 31, which are respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com