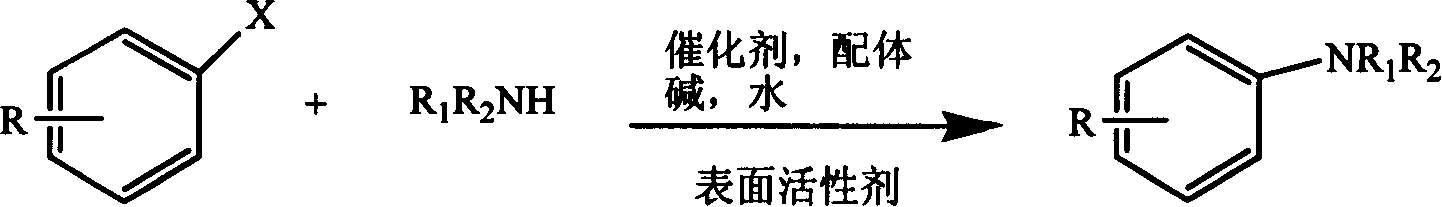

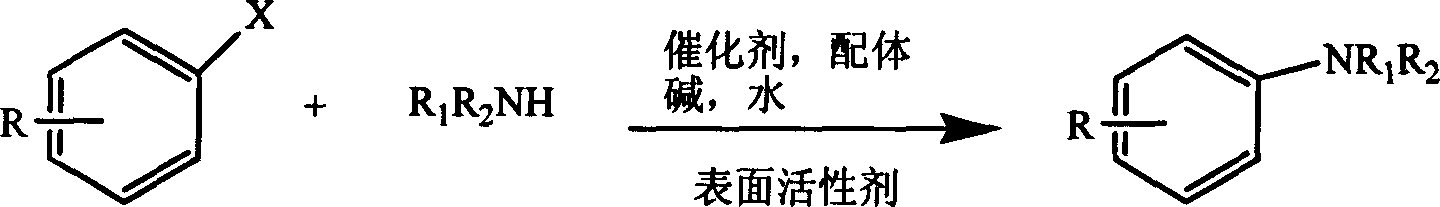

N-arylation process with hydrazone as ligand in aqueous phase system

A technology of arylation and ligands, which is applied in chemical instruments and methods, preparation of amino compounds, organic chemistry, etc., can solve the problems that cannot be popularized and used, and achieve the effects of improving environmental friendliness, low temperature, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

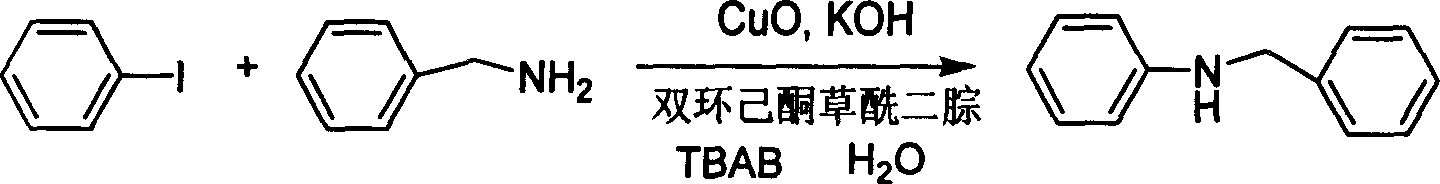

[0026] Embodiment 1: the synthesis of N-phenylbenzylamine

[0027]

[0028] 8mg (0.1mmol) CuO, 55mg (0.2mmol) dicyclohexanone oxalyldihydrazone, 102mg (0.5mmol) iodobenzene, 160mg (1.5mmol) benzylamine, 56mg (1.0mmol) KOH, 8.1mg (0.025mmol) TBAB, 1.5ml H 2 O was added to an 8ml microwave reaction tube, and reacted at 100W and 130°C for 2min. After the reaction stopped, it was extracted with ethyl acetate, washed with water, washed with saturated brine, dried over anhydrous magnesium sulfate, filtered, and the filtrate was distilled under reduced pressure, separated and purified by silica gel column chromatography [eluent: petroleum ether / ethyl acetate ( 50:1)] to obtain 82 mg of N-phenylbenzylamine, with a yield of 90%.

[0029] MS (ESI source, m / z): 184 (M + +1); 1 H NMR (CDCl 3 , 300MHz) δ7.32(dd, J=7.2, 6.6Hz, 4H), 7.24-7.26(m, 1H), 7.15(t, J=7.8, 2H), 6.69(t, J=7.2Hz, 1H) , 6.61 (d, J=7.8, 2H), 4.31 (s, 2H), 3.97 (brs, 1H).

Embodiment 2

[0030] Embodiment 2: the synthesis of N-p-nitrophenylbenzylamine

[0031]

[0032] 37mg (0.25mmol) FeSO 4, 70mg (0.25mmol) dicyclohexanone oxalyldihydrazone, 102mg (0.5mmol) p-nitrobromobenzene, 54mg (0.5mmol) benzylamine, 228mg (1.5mmol) CsF, 68mg (0.25mmol) SDS-Na, 1.5 m H 2 O was added to an 8ml microwave reaction tube and reacted at 100W at 80°C for 10min. After the reaction stopped, it was extracted with ethyl acetate, washed with water, washed with saturated brine, dried over anhydrous magnesium sulfate, filtered, and the filtrate was distilled under reduced pressure, separated and purified by silica gel column chromatography [eluent: petroleum ether / ethyl acetate ( 5:1)] to obtain 51 mg of N-p-nitrophenylbenzylamine with a yield of 45%.

[0033] MS (ESI source, m / z): 229 (M + +1); 1 H NMR (CDCl 3 , 300MHz) δ8.07(d, J=9Hz, 2H), 7.31-7.39(m, 5H), 6.56(d, J=9Hz, 2H), 4.85(brs, 1H), 4.42(s, 2H).

Embodiment 3

[0034] Embodiment 3: the synthesis of N-p-methoxyphenylbenzylamine

[0035]

[0036] 13mg (0.05mmol) CuSO 4 .5H 2 O, 20mg (0.1mmol) diacetonyl oxalyldihydrazone, 94mg (0.5mmol) p-methoxybromobenzene, 214mg (2.0mmol) benzylamine, 69mg (0.5mmol) K 2 CO 3 , 161mg (0.5mmol) TBAB, 1.5ml H 2 O was added to an 8ml microwave reaction tube, and reacted at 100W and 130°C for 5min. After the reaction stopped, it was extracted with ethyl acetate, washed with water, washed with saturated brine, dried over anhydrous magnesium sulfate, filtered, and the filtrate was distilled under reduced pressure, separated and purified by silica gel column chromatography [eluent: petroleum ether / ethyl acetate ( 30:1)] to obtain 98 mg of N-p-methoxyphenylbenzylamine with a yield of 92%.

[0037] MS (ESI source, m / z): 214 (M + +1); 1 H NMR (CDCl 3 , 300MHz) δ7.27-7.37 (m, 5H), 6.74-6.78 (m, 2H), 6.60-6.64 (m, 2H), 4.28 (s, 2H), 3.73 (s, 3H).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com