Surface-coated high hardness material for tool

A technology with surface coverage and high hardness, which is applied in the manufacture of tools, metal material coating processes, workpieces, etc., can solve the problems of reduced machining accuracy and higher cutting resistance, and achieve excellent hardness, heat resistance, and improved defect resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

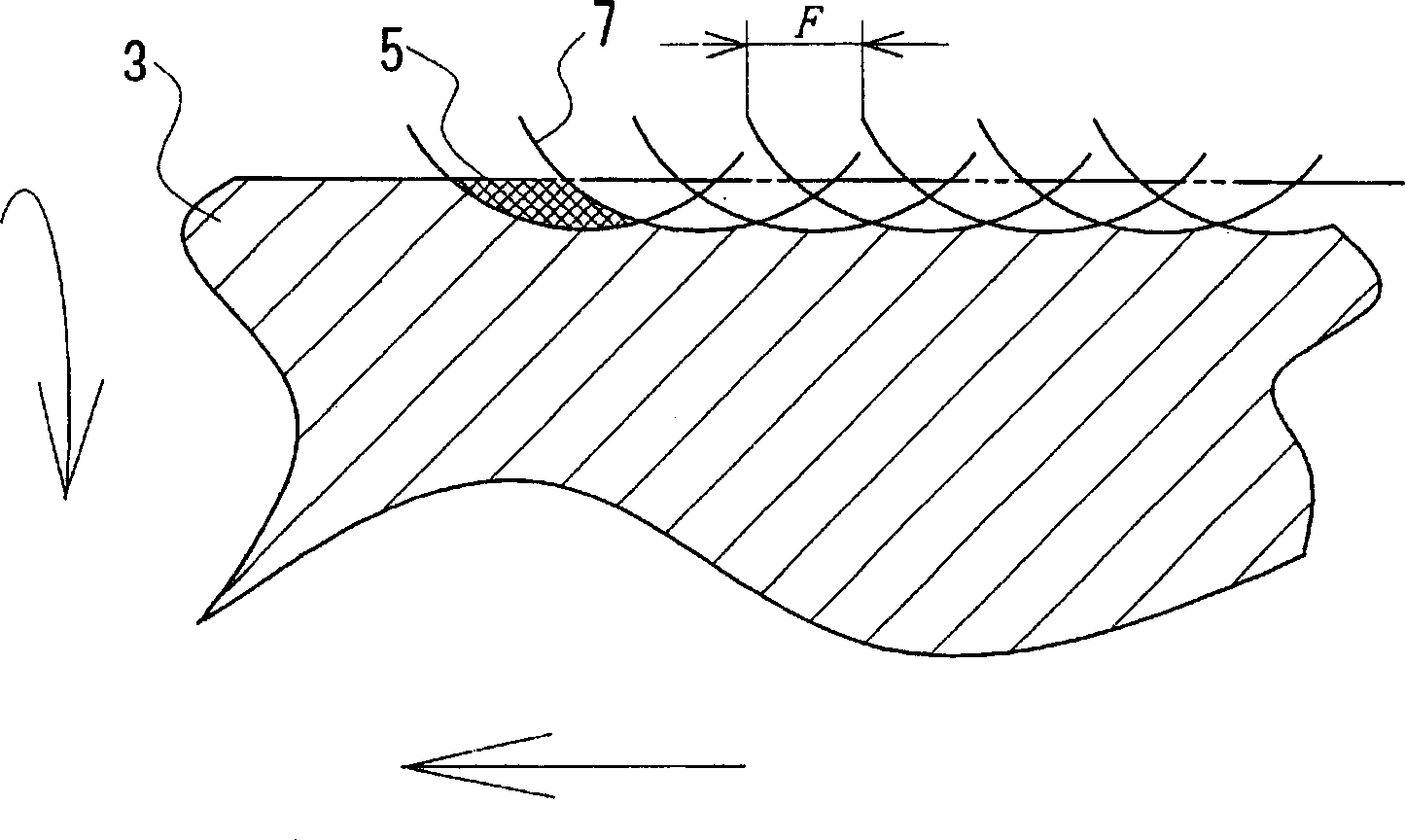

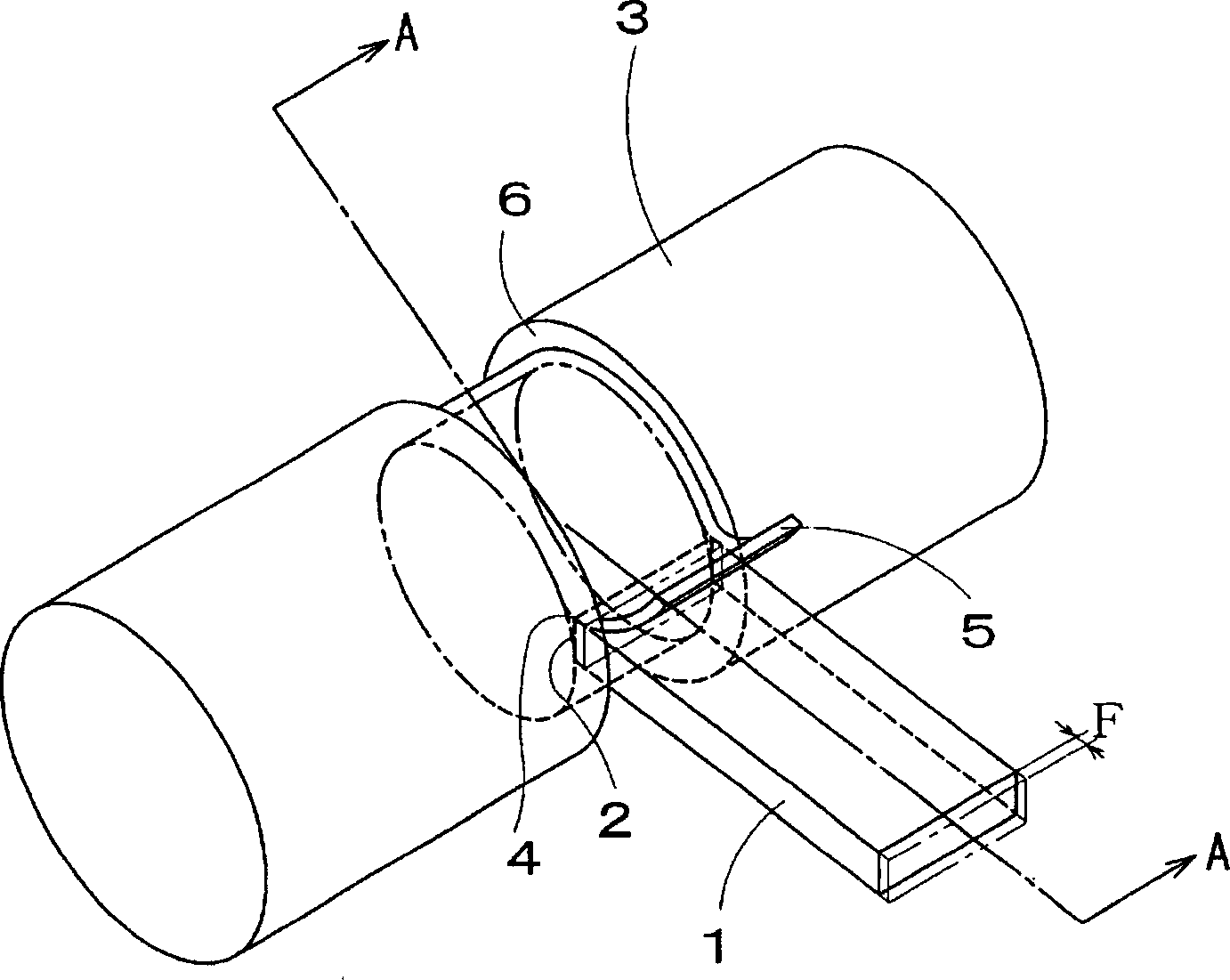

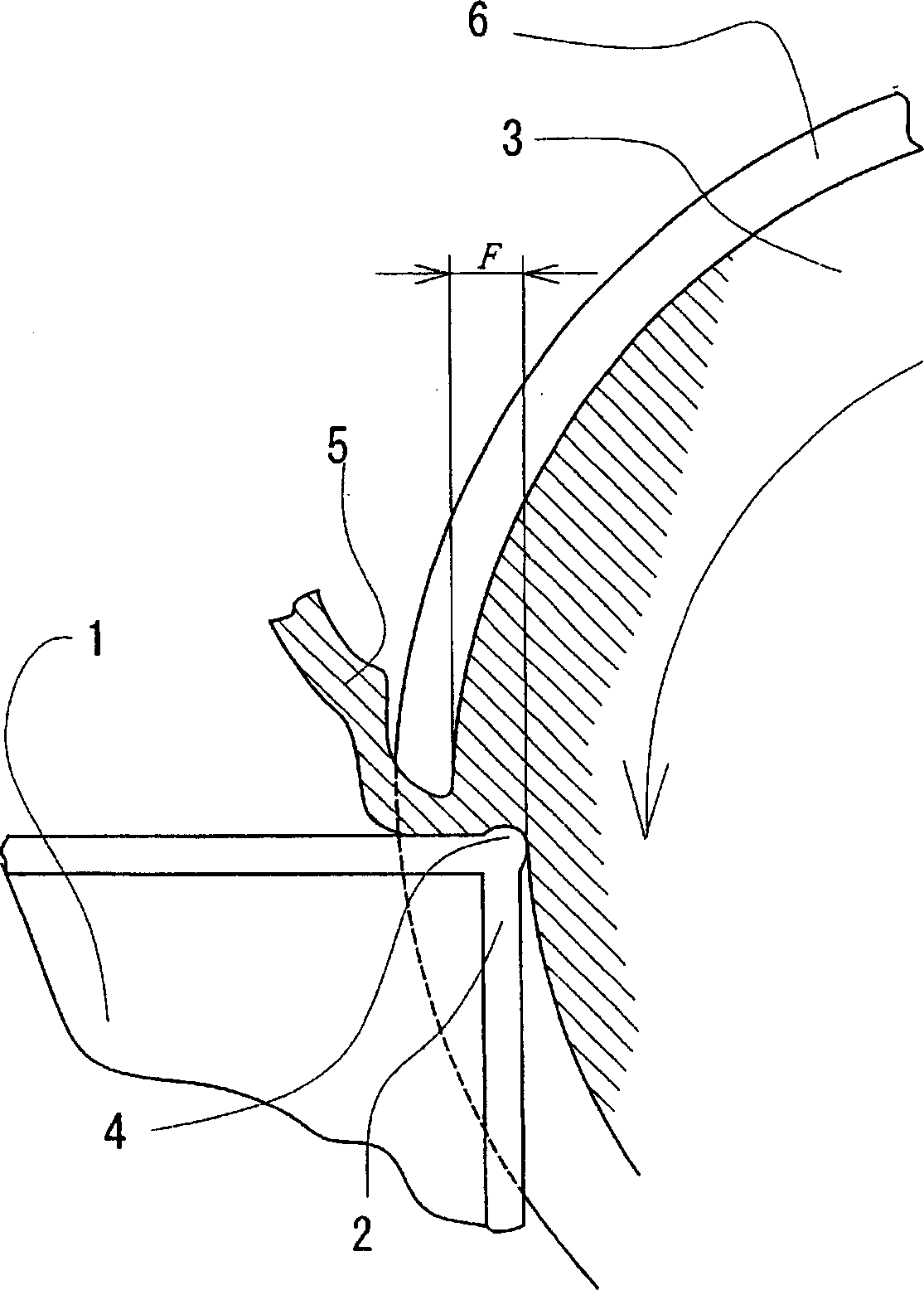

Method used

Image

Examples

Embodiment 1

[0038] A binder powder in which TiN and aluminum were mixed at a weight ratio of 80:20 was obtained using a pot and a base made of cemented carbide. Next, this bonding material and CBN powder were prepared at a volume ratio of 40:60, filled into a Mo container, and sintered at a pressure of 50 kb (5 GPa) and a temperature of 1450° C. for 20 minutes. In the sintered body, aluminum compounds known as aluminum nitride, aluminum oxide, and aluminum boride are contained. After processing this sintered body into the shape of a chip for cutting tools (model number SNGN120408) and the shape of a blade for grooving tools (model number BNGNT0250R), the chips described in Table 1 were covered by vacuum arc discharge ion plating. cover film shown.

[0039] In the film forming apparatus, a plurality of targets are arranged, and the above-mentioned blade is mounted on a rotary substrate holder provided around these targets to form a film. As the target, Ti with the same composition as the...

Embodiment 2

[0093] The effect of changing the crystal orientation and average particle size was investigated. Similar to Example 1, the surface of the tool is covered with a high-hardness material and processed into an insert shape (model number SNGN120408). However, the film thickness, X-ray diffraction intensity I(200) / I(111), and average crystal grain size were varied in various ways. In this example, a wear-resistant layer was fabricated to (Ti 0.6 al 0.4 ) N-based, the tools without the most surface layer and the middle layer are covered with high-hardness materials on the surface. When the bias voltage is increased, the value of I(200) / I(111) tends to be smaller, and the average crystal grain size becomes smaller as the bias voltage becomes higher, and becomes smaller as the film thickness becomes thinner. tendency. The properties of the inserts thus obtained are shown in Table 8.

[0094] Sample No.

Bias voltage (V)

wear layer

composition

film th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com