Prepn process and use in repairing bone defect of calcined bone powder

A technology of calcining bone and calcining, which is applied in the field of preparation of medical and sanitary materials to achieve good biocompatibility and good tissue compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Pretreatment of Calcined Bone

[0030] According to the principle that the strength and porosity of the selected bones are basically similar to those of human bones, the one-year-old bovine spine was selected as the object of treatment.

[0031] Cut the freshly sacrificed beef spine into 10mm 3 Small pieces, washed several times with clean water, and then boiled in a pot. The main purpose of this process is to remove the organic matter attached to the beef bones, such as: gelatin, bone marrow, protein, etc. This process takes 4 to 5 hours.

[0032] After the above-mentioned processed bovine bone is dried in a drying oven, the bovine bone is crushed into about 5mm with a pulverizer. 3 Put the small pieces into the pot and cook again to remove most of the organic matter. This process takes about 3 hours to change the water 3 times, and dry it for later use.

[0033] Put the above-mentioned bovine bone into 1M NaOH or sodium bicarbonate solution a...

Embodiment 2

[0037] Preparation method of calcined bone meal

[0038] The prepared bovine bone blocks were put into a high-temperature furnace (model: Tube Furnace 21100, Germany) and calcined at different temperatures. Below only the experimental situation table comparison under different temperatures (see table 1):

[0039] temperature °C

apparent state

physical properties

Processing time (hours)

150

No change in color (white)

no change in intensity

3

250

color starts to turn black

ditto

3

350

color is black

ditto

3

450

ditto

ditto

3

550

light gray

ditto

3

650

color turns white

weakened

3

800

White

ditto

3

[0040] In this experiment, bone powders with different calcination temperatures were compared. When the calcination temperature was 150°C, soft tissue remained in the p...

experiment example 1

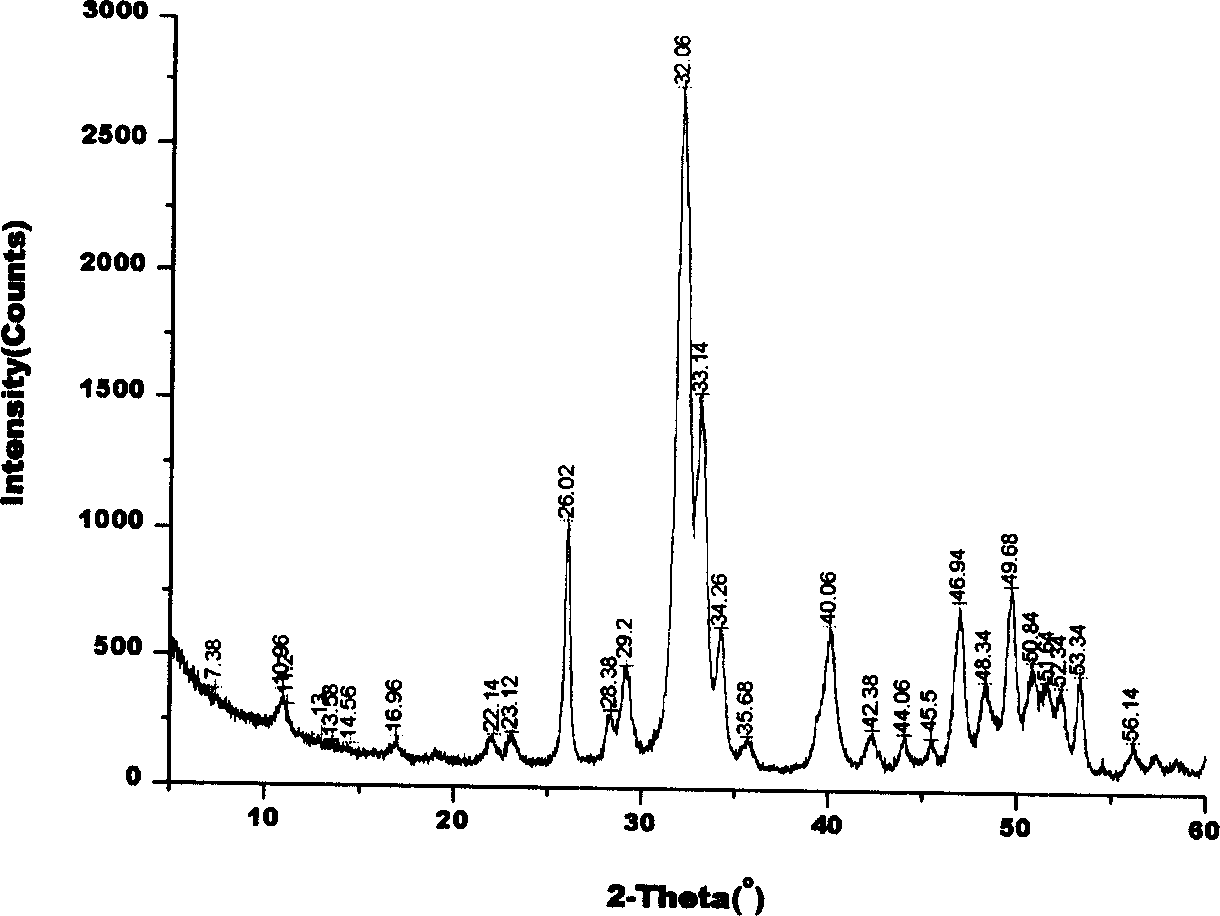

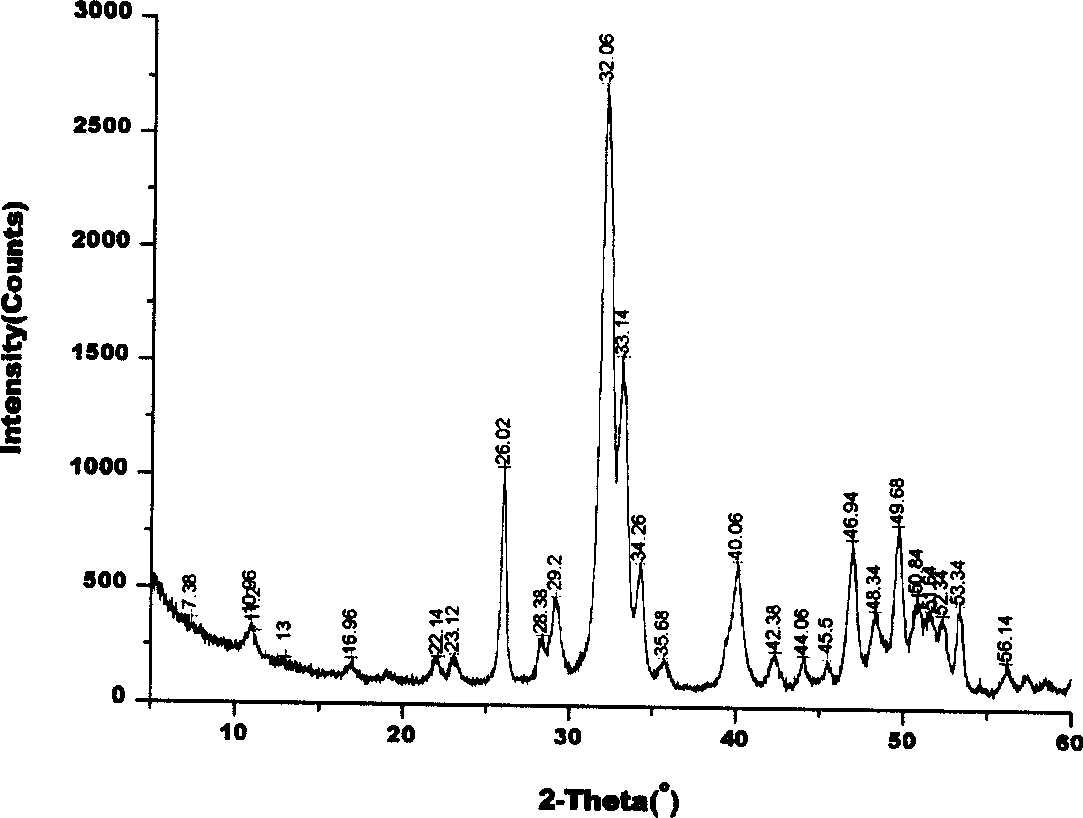

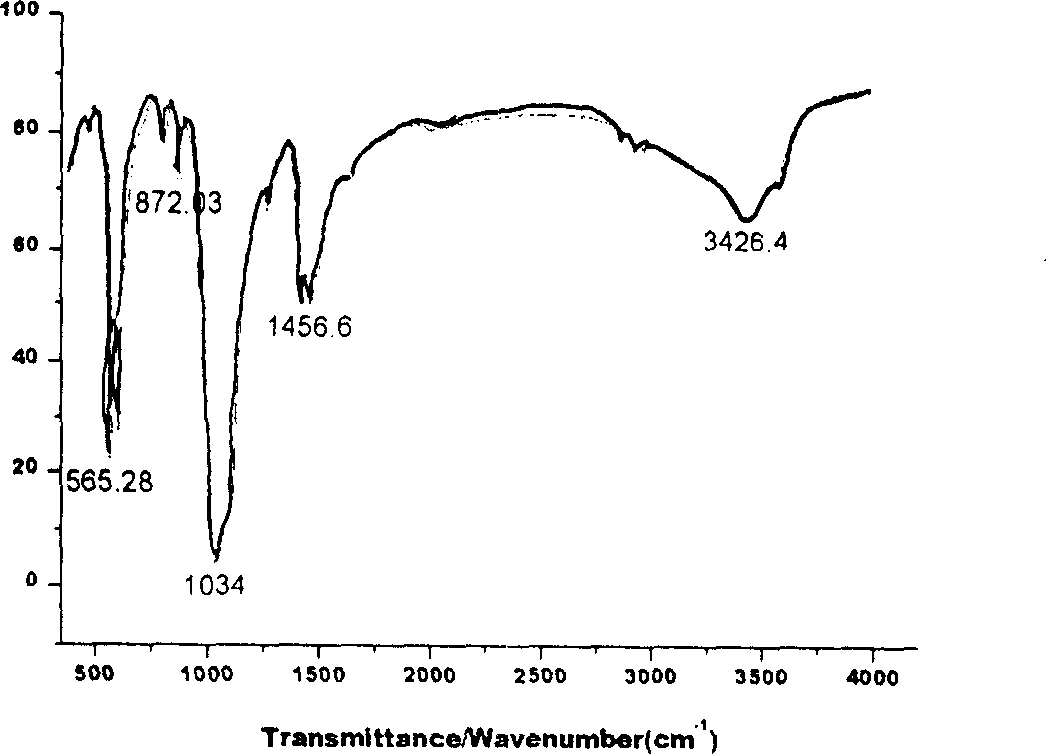

[0045] X-ray (Powder) Diffraction Analysis of Calcined Bone Powder

[0046] Instrument model: Rigaku D / max 2500V PC X-ray diffractometer.

[0047] Working conditions: Cu rake, 40kv, 200mA, continuous scanning of the standard sample stage.

[0048] Scanning speed: 4.000deg / min.

[0049] Sample feeding width: 0.020deg.

[0050] Scan axis: 2Theta / thetan.

[0051] Scanning range: 5.000≥60.000deg.

[0052] Carry out X-ray diffraction analysis to the calcined bone meal of the present invention, its composition is as a result figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com