Method for rectifying and separating methylal-methanol-water by adding salt composite extracting

A technology of extractive distillation and methylal, which is applied in the field of compound extraction and rectification with salt, can solve the problems of high energy consumption, high energy consumption in the separation process, and complicated separation process, and achieve low energy consumption, reduced energy consumption, The effect of simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

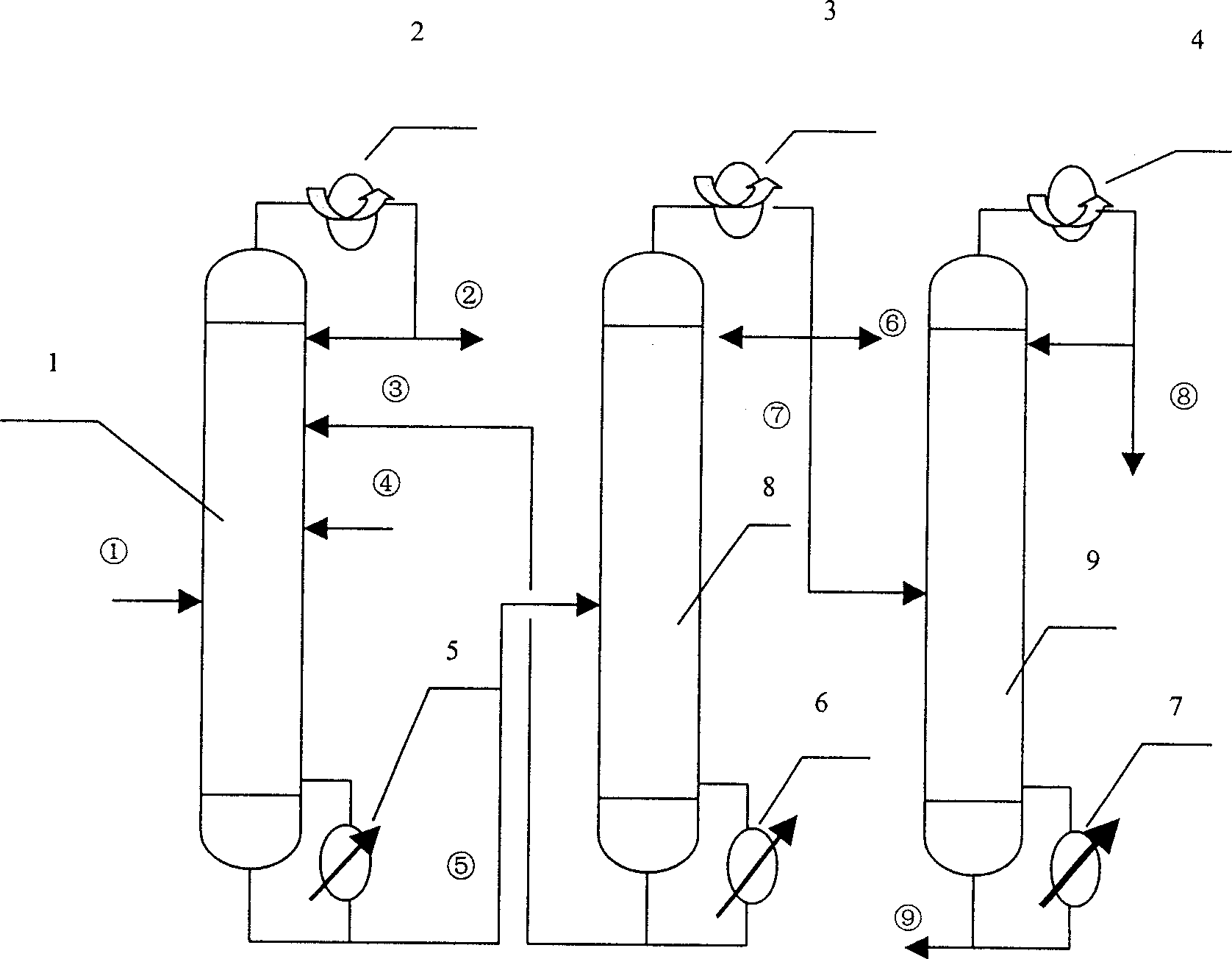

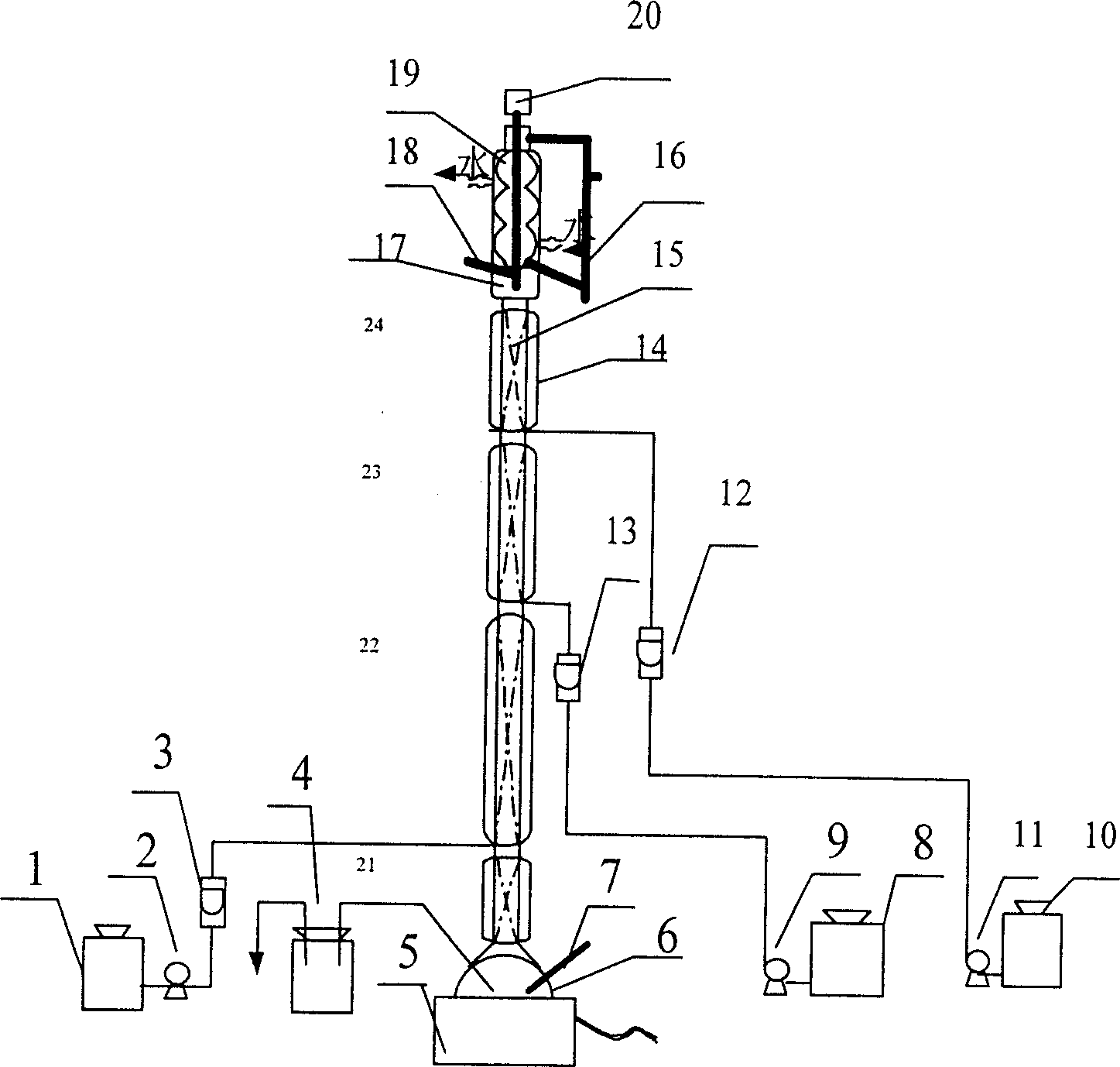

[0019] Embodiment 1, composite extraction experimental device reference figure 1 , figure 2 , where 1 is the raw material storage tank, 2 is the pump, 3 is the glass rotameter, 4 is the sampler of the tower kettle, 5 is the electric heating mantle, 6 is the tower kettle, 7 is the thermometer of the tower kettle, 8 is the solvent 2 storage tank, 9 10 is the solvent 1 storage tank, 11 is the pump, 12 is the glass rotameter, 13 is the glass rotameter, 14 is the glass fiber cotton and the jacket, 15 is the packing, 16 is the top sampler, 17 is Return port, 18 is a tower top thermometer, 19 is an electromagnetic rod, and 20 is a condenser. The methylal-methanol-water mixed solution synthesized by methanol and formaldehyde was used as raw material, and analyzed by SP-6800 chromatograph, the composition is shown in Table 2, and the composition in the table is the mass content. The raw material liquid is extracted and separated by a salt-added compound extraction tower. The tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com