Process for preparing coated ZrB2 composite powder

A composite powder, coating technology, applied in the field of preparation of coated inorganic powder, can solve problems such as performance degradation, and achieve the effects of good anti-oxidation performance, excellent physics, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

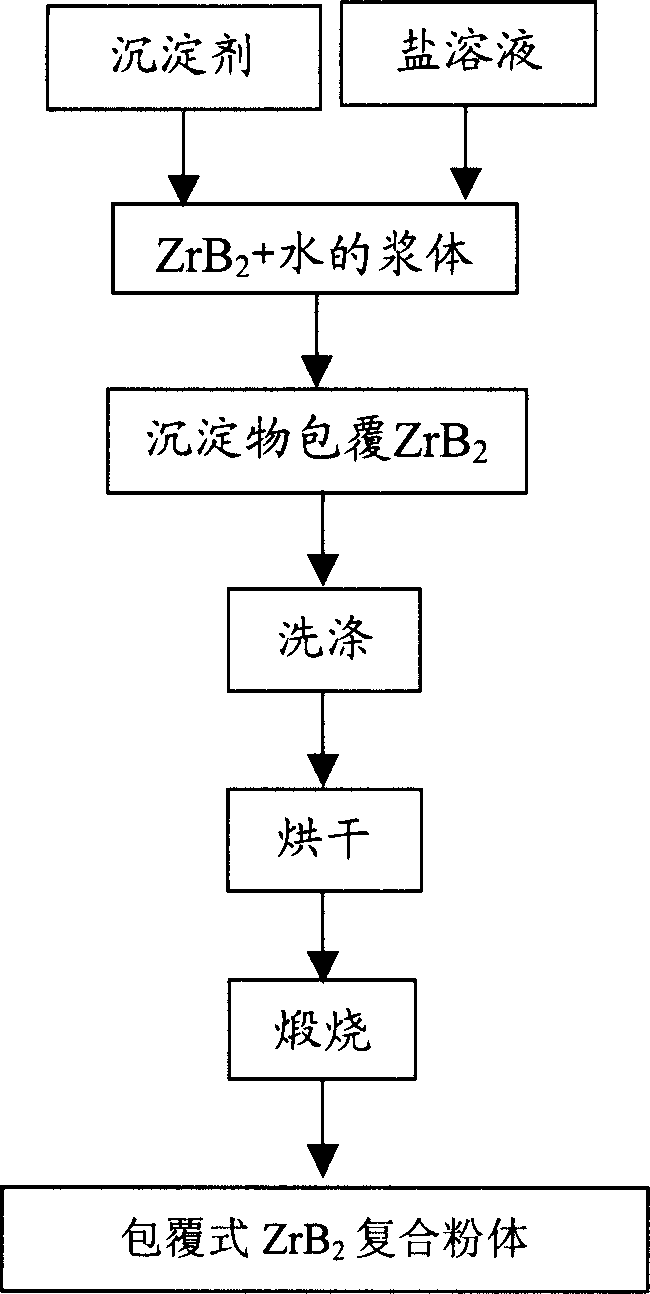

Method used

Image

Examples

Embodiment 1

[0019] 3 g ZrB 2 Add the powder into 200ml of water, ultrasonically disperse for 5 minutes, and stir evenly to obtain ZrB 2 Slurry of powder and water; drop 300ml of mixed solution (150ml of 0.12mol / L aluminum nitrate and 150ml of 0.2mol / L yttrium nitrate) into the slurry at a constant speed in 180 minutes, and drop the precipitant of pH=11 at the same time Ammonia regulates ZrB 2 The pH value of the slurry is always 9. Stir continuously with a stirrer. After the mixed solution is added dropwise, continue to stir for 1 hour, and keep the pH value at 9 to obtain the precursor of the coating layer coated ZrB 2 The composite powder of the powder; the composite powder was washed three times and once with deionized water and absolute ethanol respectively, then dried at 80°C and calcined at 500°C to obtain Al 2 o 3 and Y 2 o 3 co-coated ZrB 2 Coated ZrB powder particles 2 Composite powder. Coated ZrB 2 The thickness of the cladding layer of the composite powder is about 30n...

Embodiment 2

[0021] 3 g ZrB 2 Add the powder into 200ml of water, ultrasonically disperse for 5 minutes, and stir evenly to obtain ZrB 2 A slurry of powder and water; drop 200ml of 0.05mol / L zirconium hypochlorite solution into the slurry at a constant speed for 120 minutes, and drop the precipitant ammonia water with pH=11 at the same time to adjust ZrB 2 The pH value of the slurry is always 9, and the stirrer is used to stir continuously. After the zirconium hypochlorite solution is added dropwise, the stirring is continued for 1 hour, and the pH value is kept at 9, and the precursor coated ZrB of the coating layer is obtained. 2 The composite powder of the powder; the composite powder was washed three times and once with deionized water and absolute ethanol respectively, then dried at 100°C and calcined at 600°C to obtain ZrO 2 Coated ZrB 2 Coated ZrB powder particles 2 Composite powder. Coated ZrB 2 The thickness of the coating layer of the composite powder is about 25nm, dense an...

Embodiment 3

[0023] 3 g ZrB 2 Add the powder into 150ml of water, ultrasonically disperse for 5 minutes, and stir evenly to obtain ZrB 2 Slurry of powder and water; drop 150ml of 0.15mol / L yttrium sulfate solution into the slurry at a constant speed in 180 minutes, and drop sodium hydroxide solution of pH=10 at the same time as a precipitant to adjust ZrB 2 The pH value of the slurry is always 9. Stir continuously with a stirrer. After the mixed solution is added dropwise, continue to stir for 1 hour, and keep the pH value at 9 to obtain the precursor of the coating layer coated ZrB 2 The composite powder of the powder; the composite powder was washed three times and once with deionized water and absolute ethanol respectively, then dried at 80°C and calcined at 500°C to obtain Y 2 o 3 Coated ZrB 2 Coated ZrB powder particles 2 Composite powder. Coated ZrB 2 The thickness of the cladding layer of the composite powder is about 20nm, dense and uniform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com