Growth method for gallium nitride film using multi-hole gallium nitride as substrate

A substrate, epitaxial growth technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as low stress, improve crystal quality, reduce dislocation density, and simplify the electrochemical corrosion process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

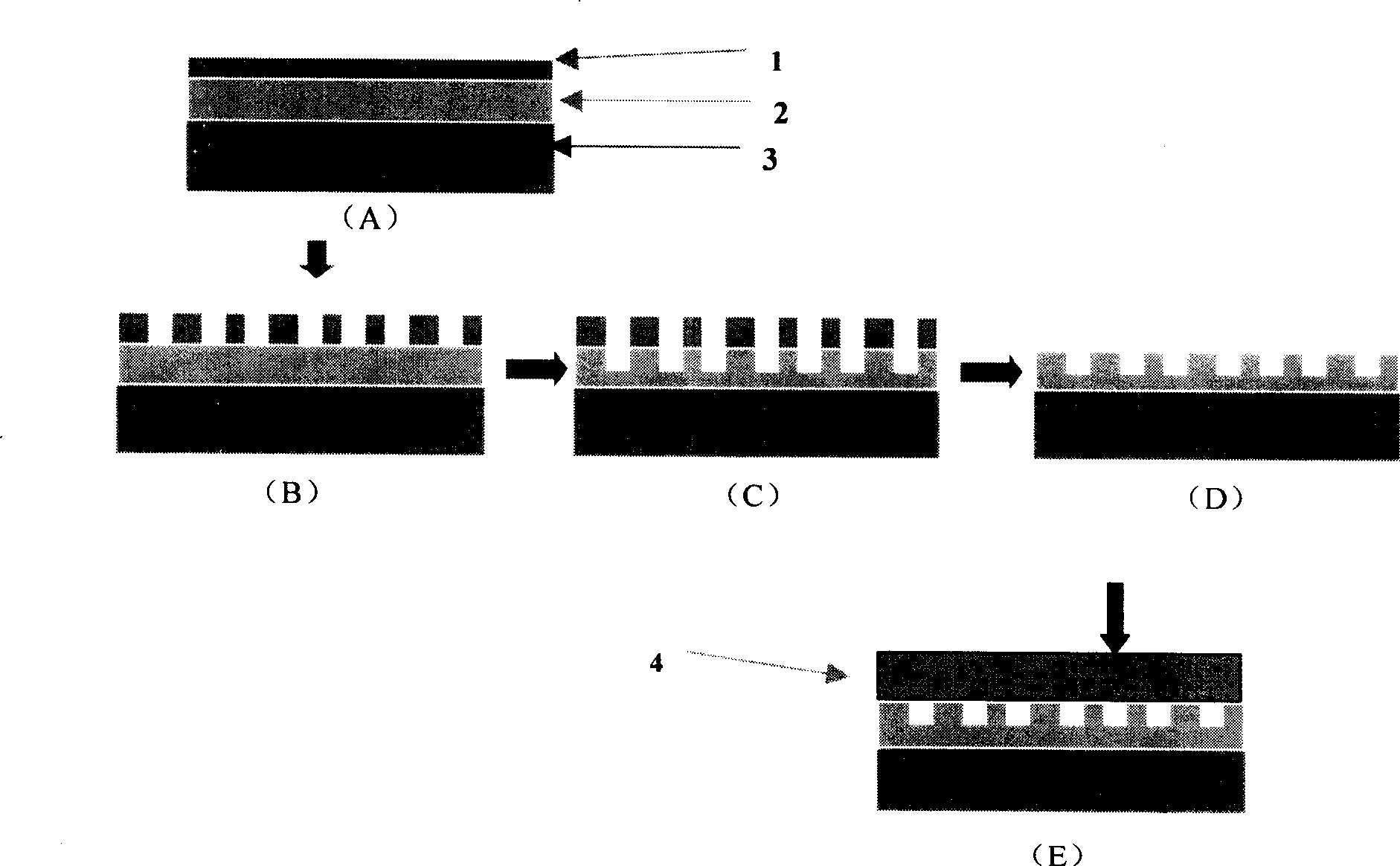

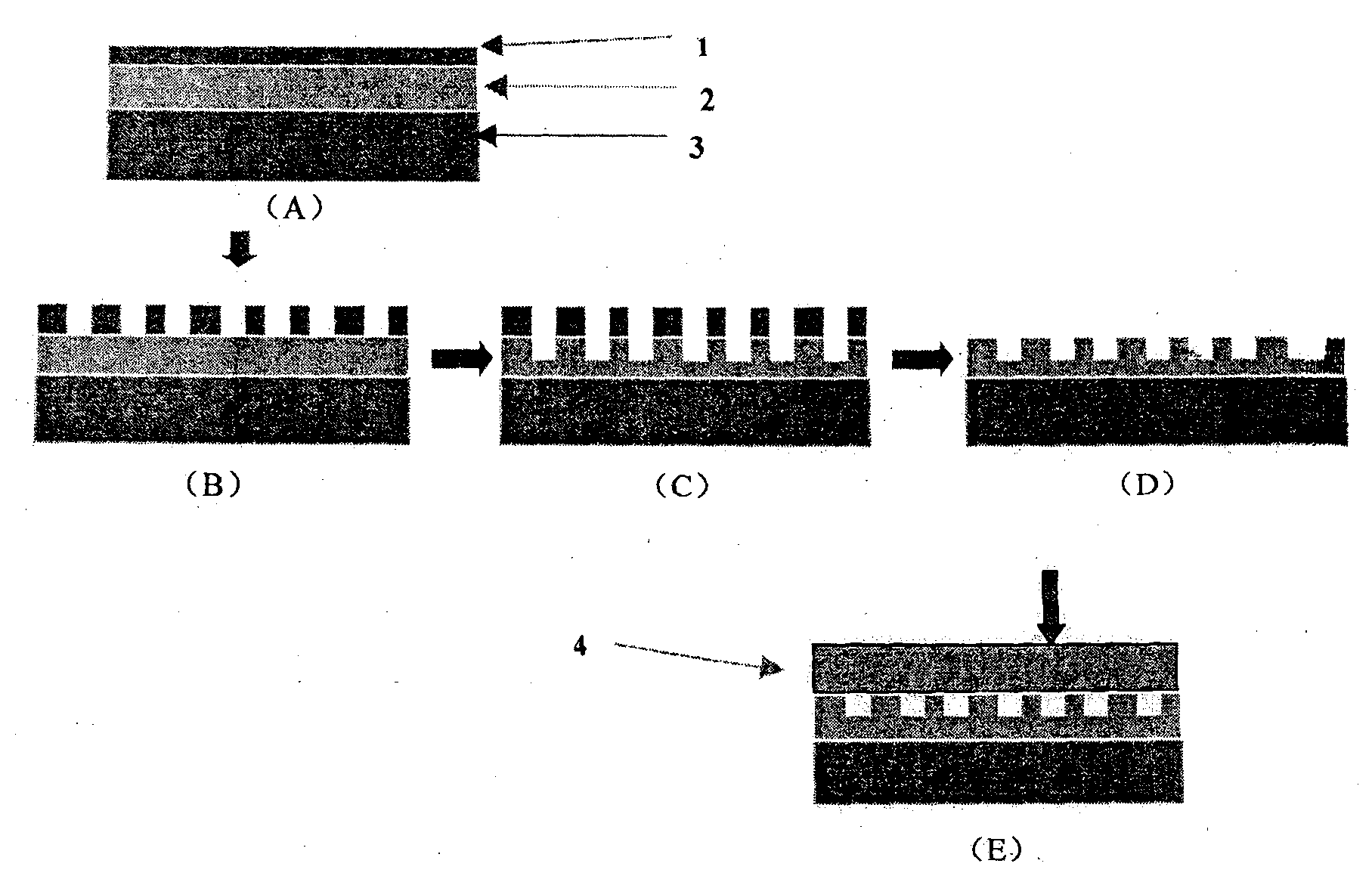

Method used

Image

Examples

Embodiment 1

[0027] First, MOCVD was used to grow Al 2 o 3GaN on the substrate is used as a template, and then a thin layer of metal Al with a thickness of 70nm is deposited on the template by electron beam evaporation at a temperature of 300°C, and then the template with the metal layer is placed in an oxalic acid solution (0.3mol / L ), use 40 volts to oxidize at room temperature for 4 minutes, and then soak the template in phosphoric acid solution (5wt%) for 30 minutes to remove the part of the aluminum oxide at the bottom of the hole that is in contact with the lower layer of GaN, so that the etched Mask of porous GaN. Then put the template into inductively coupled plasma (ICP) for etching, and then use 0.2 mol / L NaOH solution to remove the anodized aluminum, thus obtaining the porous GaN substrate. Finally put the substrate into the HVPE reaction chamber, under N 2 The atmosphere is heated to 800°C, and NH 3 The GaN layer of the protection template is grown by HCl at 1050°C. The sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com