Surface adhesive broadband microwave single-layer chip capacitor and manufacturing method thereof

A single-layer chip and manufacturing method technology, applied in the field of capacitors, can solve the problems of component cracking, SLC component usage restrictions, high cost, etc., and achieve the effects of increased working voltage, improved reliability, and fewer electrodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

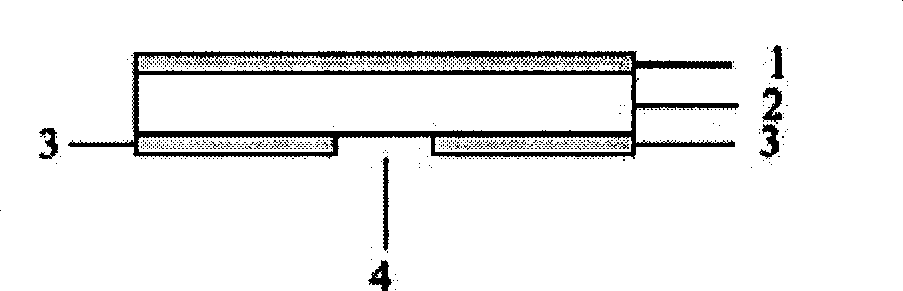

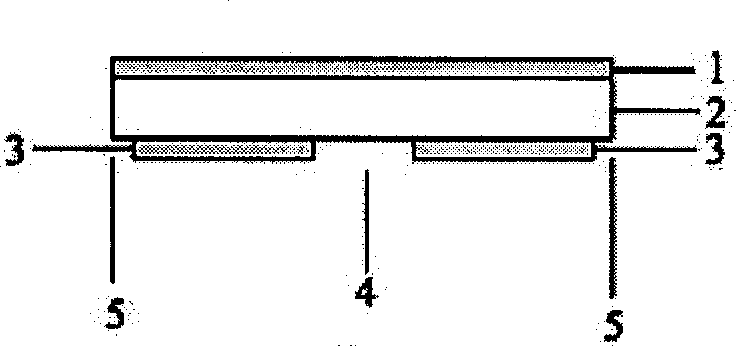

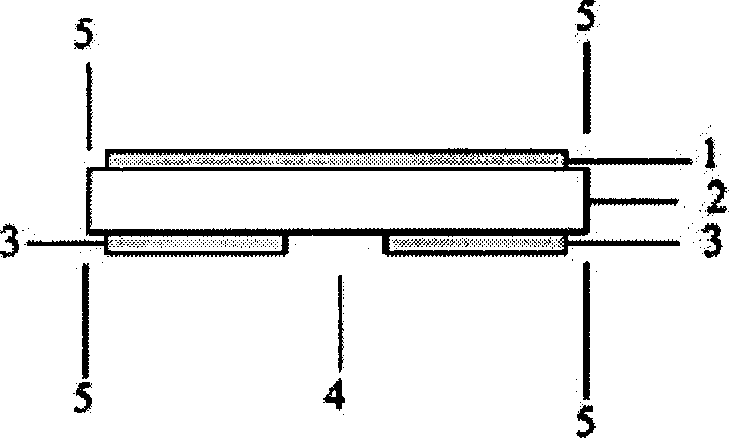

[0039] Such as Figure 1-9 The surface-mounted broadband microwave single-layer chip capacitor shown includes a single-layer ceramic dielectric 2, an upper electrode 1 and a lower electrode 3, and the upper electrode 1 and the lower electrode 3 are respectively attached to two opposite sides of the ceramic dielectric 2. On one surface, the lower electrode 3 is divided into two, and an electrode gap 4 is left between the two lower electrodes 3 .

Embodiment 1

[0042] Such as figure 1 As shown, there is no border between the upper electrode 1 and the lower electrode 3 and the surface of the ceramic medium 2 to which they are attached.

Embodiment 2

[0044] Such as figure 2As shown, there is a margin 5 around the bottom electrode 3 and the surface of the ceramic medium 2 to which it is attached.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com