Soy bean protein/aluminium hydrate nano composite material, its prepn. and uses

A nano-composite material and soybean protein technology, applied in the fields of polymer materials and environmental science, can solve the problems of difficulty in processing soybean protein, reduce the tensile strength of materials, etc., and achieve superior product performance, low production cost, and high water resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

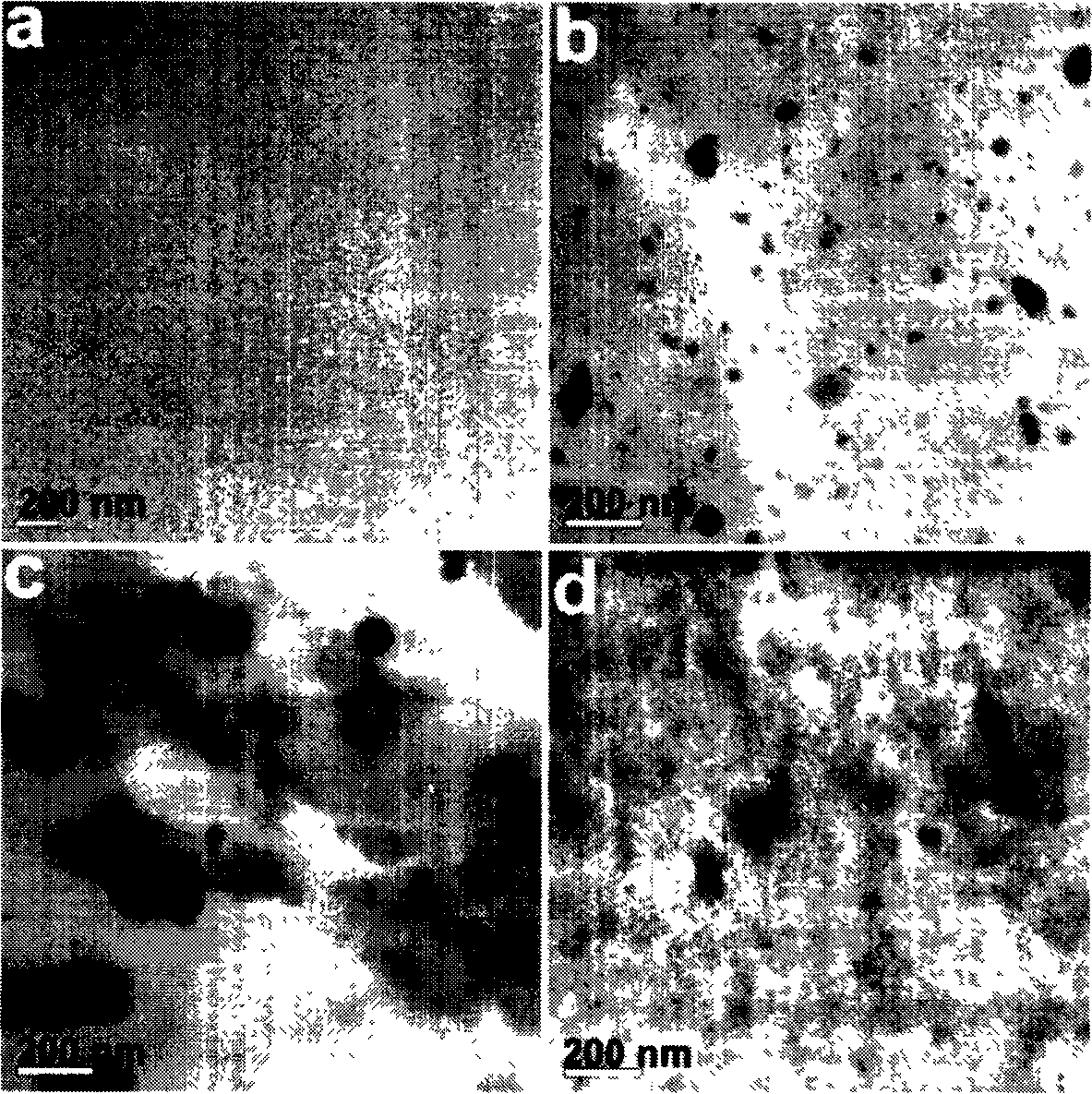

Image

Examples

Embodiment 1

[0009] Example 1: Disperse 10 g of soy protein (SPI) in an aluminum chloride aqueous solution with a concentration of 0.1 wt% and stir vigorously, and then slowly add ammonia water dropwise. The rate of the dropwise addition of ammonia water is 5 g / min, and the reaction time is 0.5 h. The molar ratio of ammonia to aluminum chloride is 4:1. The obtained gel-like composite was centrifuged at 7000 rpm and dried at 70° C. to prepare the SPI / aluminum hydroxide nanocomposite. According to the ratio of glycerin to soybean protein mass ratio of 3:7, glycerin and soybean protein / aluminum hydroxide nanocomposite were mixed. The extruder screw speed: 100rpm, the single screw extruder has three temperature settings from the feed port to the extrusion die: 80, 100 and 120°C. Finally, the soy protein plastic sheet modified and modified by nano aluminum hydroxide was obtained by hot pressing at 140° C. and 20 MPa for 10 minutes, which was numbered AS-1.

Embodiment 2

[0010] Example 2: Disperse 10g of soy protein (SPI) in an aqueous aluminum chloride solution with a concentration of 1wt% and stir vigorously, and then slowly add ammonia water dropwise. The rate of the dropwise addition of ammonia water is 5g / min, the reaction time is 1h, and the ammonia water and The molar ratio of aluminum chloride is 4:1. The obtained gel-like composite was centrifuged at 8000 rpm and dried at 70° C. to prepare the SPI / aluminum hydroxide nanocomposite. According to the ratio of glycerin to soybean protein mass ratio of 3:7, glycerin and soybean protein / aluminum hydroxide nanocomposite were mixed. The extruder screw speed: 60rpm, the single-screw extruder has three temperature settings from the feed port to the extrusion die: 100, 120 and 140°C. Finally, it was hot-pressed at 140° C. and 20 MPa for 10 minutes to obtain a nano-aluminum hydroxide modified soybean protein plastic sheet, numbered AS-2.

Embodiment 3

[0011] Example 3: Disperse 10g of soy protein (SPI) in a 3wt% aluminum chloride aqueous solution with strong stirring, then slowly add ammonia water dropwise, the rate of the dropwise addition of ammonia water is 5g / min, the reaction time is 3h, the ammonia water and The molar ratio of aluminum chloride is 4:1. The obtained gel-like composite was centrifuged at 7500 rpm and dried at 70° C. to prepare the SPI / aluminum hydroxide nanocomposite. According to the ratio of glycerin to soybean protein mass ratio of 3:7, glycerin and soybean protein / aluminum hydroxide nanocomposite were mixed. Extruder screw speed: 30rpm, single-screw extruder has three temperature settings from the feed port to the extrusion die: 100, 120 and 140°C. Finally, the soy protein plastic sheet modified and modified by nano aluminum hydroxide was obtained by hot pressing at 140° C. and 20 MPa for 10 minutes, which was numbered AS-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com