Salangane saponin and preparation method and use thereof

A technology of petrel and saponin, which is applied to the new application of petrel saponin in expectorant and asthma, and in the field of antitussive, which can solve the problems of complicated preparation process of petrel saponin and unstable quality of saponin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

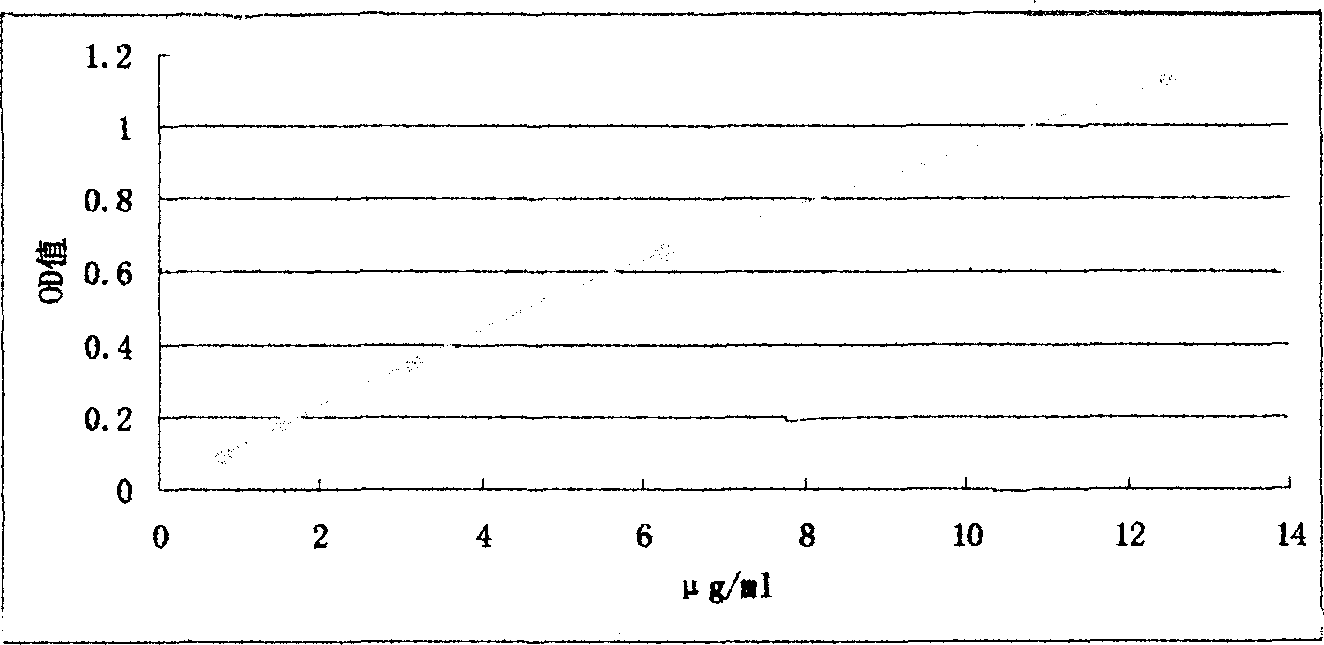

[0091] Example 1, put the fresh petrel in a cool and dry place to air-dry, crush it into 20-40 mesh particles with a traditional Chinese medicine grinder, weigh 10Kg of petrel dry powder, add 200Kg of 80% ethanol, extract at room temperature for 144h, and extract the extract at 0.08MPa, 50 Concentrate under reduced pressure at ℃ to obtain 10L concentrated solution, which is adsorbed on the AB-8 macroporous resin column at a rate of 5L / h. The amount of macroporous resin is 10Kg, and the adsorption volume is determined to be 5000ml. , first use 50L distilled water to elute the macroporous resin column, and control the elution rate to be 15L / h, then use 50L 20% ethanol, 50L 50% ethanol, 50L 80% ethanol to elute in sequence, and control the elution rate to be 5L / h h, collect the above-mentioned 50% ethanol eluate, concentrate under reduced pressure at 0.08MPa, 50°C, and dry under vacuum at 0.08MPa, 50°C to obtain petrel saponin. The hemolytic activity test shows that the hemolytic ...

Embodiment 2

[0092] Example 2, directly grind 10Kg of fresh petrel into 20-60 mesh particles with a meat grinder, add 100L of 80% ethanol, extract at room temperature for 72 hours, collect the extract, decompress the extract at 0.08MPa, and 50°C Concentrate to get 2L of concentrated solution. The above-mentioned concentrated solution is adsorbed on the NKA macroporous resin column at a speed of 1L / h. The amount of macroporous resin is 2Kg, and the adsorption volume is measured as 800ml. After the adsorption is completed, first use 5L of distilled water to Pore resin column was eluted, and the elution rate was controlled to be 1.5L / h, and then eluted sequentially with 8L of 20%, 50%, and 80% ethanol, and the elution conditions were the same as those eluted with distilled water. The eluate was concentrated under reduced pressure and freeze-dried to obtain petrel saponins.

Embodiment 3

[0093] Example 3, after freezing 10Kg of fresh petrel, grind it into 20-60 mesh particles with a meat grinder, add 30L of methanol, extract at room temperature for 12 hours, collect the extract, and concentrate the extract under reduced pressure at 0.08MPa and 50°C , to get concentrated solution 2L, above-mentioned concentrated solution is adsorbed on NKA-9 macroporous resin column with the speed of 1L / h, and the consumption of macroporous resin is 2Kg, and adsorption volume is measured as 1000ml, after adsorption finishes, first use 4L distilled water to The macroporous resin column is eluted, and the elution rate is controlled to be 1L / h, and then eluted successively with 4L of 20%, 50%, and 80% ethanol respectively. The elution conditions are the same as elution with distilled water, and the above 50% ethanol The eluate was concentrated under reduced pressure and freeze-dried to obtain petrel saponins.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com