Process for producing oxide thin film and production apparatus therefor

A technology of oxide film and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, gaseous chemical plating, coating and other directions, can solve the problems of many defects, worsened ferroelectric properties, and increased leakage current density, etc. Defect improvement, less leakage current, and alignment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

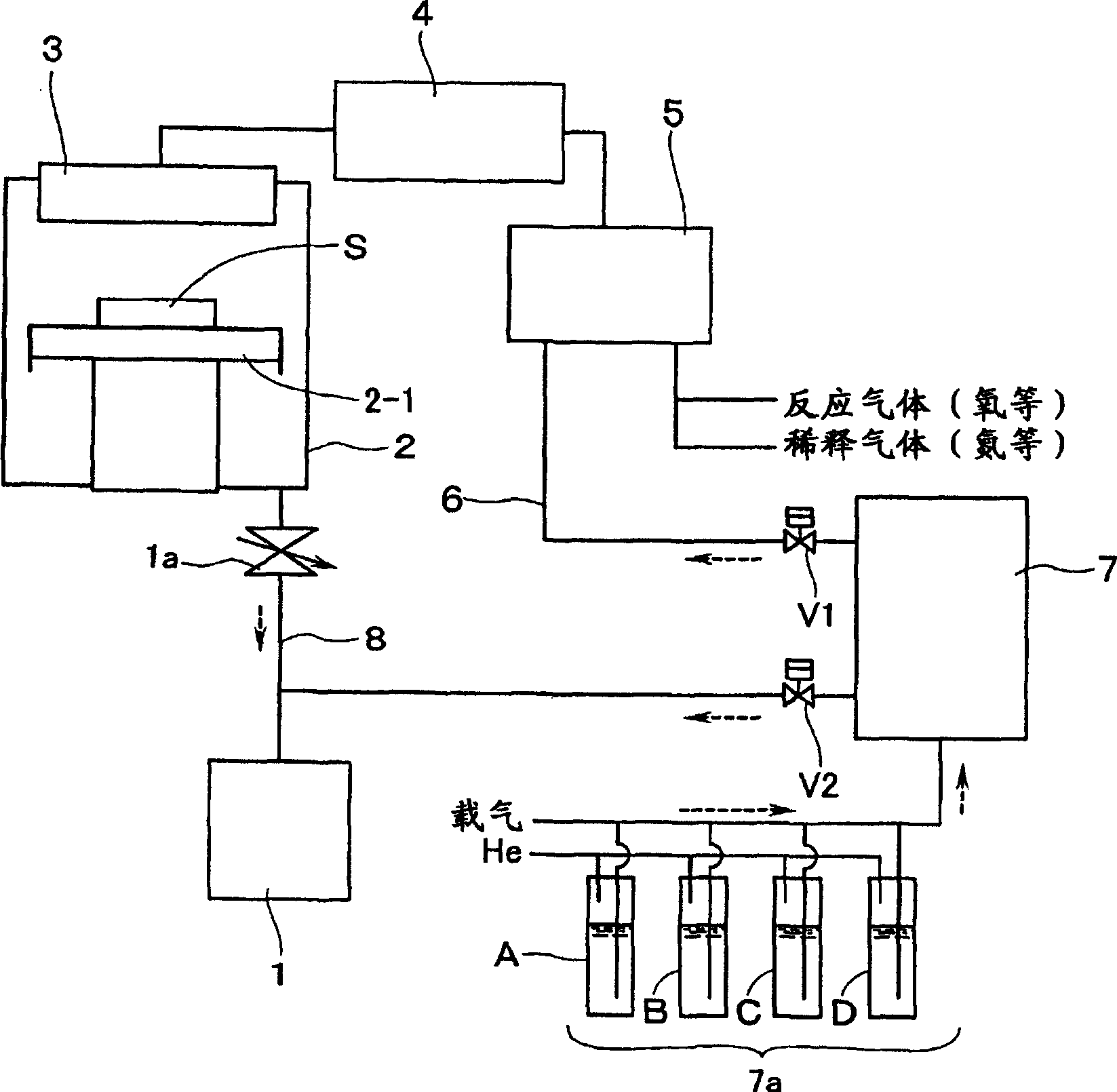

[0078] Add the solid raw material Pb (thd) dissolved in the concentration of 0.3mol / L respectively in the tetrahydrofuran (THF) solvent 2 、Zr(dmhd) 4 、Ti(i-PrO) 2 (thd) 2 Containers A, B, and C of raw materials and THF-filled container D are pressurized with helium and sent to the vaporizer 7 with nitrogen as a carrier gas. Gasification is carried out in the gasifier. The raw material gas obtained by vaporization is sent to the gas mixer 5 through the pipe 6, mixed with oxygen (flow rate 3500 sccm) as the oxidizing gas and nitrogen (300 sccm) as the diluent gas (carrier gas) in the gas mixer 5, and then passed through the gas The activation means 4 sends the mixed gas to the jetting plate 3, passes through the jetting plate, and introduces it onto the substrate S placed in the reaction chamber 2 and heated to 620° C. to deposit and form a PZT thin film.

[0079] In the above process, the pressure of the reaction chamber is adjusted to about 667Pa by the pressure regulating...

Embodiment 2

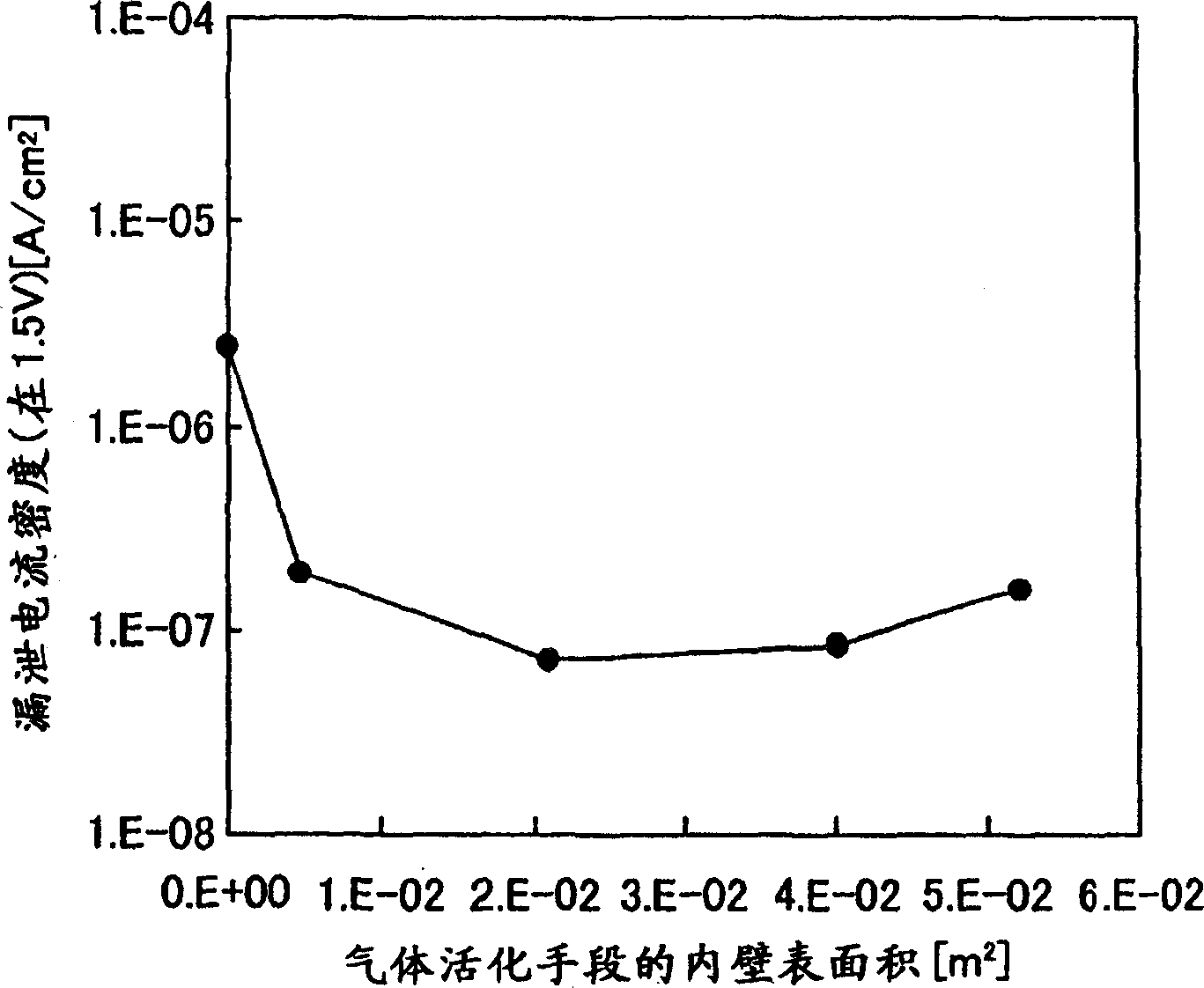

[0084] This example describes the dependence of the inner wall surface of the gas activation means disposed between the gas mixer and the injection plate on the properties of the PZT thin film.

[0085] image 3 Indicates the surface area of the inner wall of the gas activation means (m 2 ) and the leakage current density (A / m 2 ) dependencies. In this case, the ratio of the oxygen gas flowing into the reaction chamber 2 to the total supply gas was 91%. As the substrate, an Ir(111) oriented film was used. Leakage current density when not using gas activation means (internal surface area 0m 2 ) is 2.5E-6A / cm 2 , The surface area of the inner wall is 4.8E-3m 2 It is 2.0E-7, but it decreases when the surface area of the inner wall is increased, and the surface area of the inner wall is 2.1E-2m 2 When showing the minimum value of 7.5E-8A / cm 2 . If the surface area of the inner wall is increased, the leakage current density increases, and the surface area of th...

Embodiment 3

[0091] This example describes the dependence of the ratio of oxygen flow on the properties of PZT thin films.

[0092] Figure 6 It shows the dependence of the oxygen flow rate ratio of the total gas introduction in the mixed gas and the leakage current density when 1.5V is applied to the PZT film. In this case, the oxygen flow ratio is changed from 0.5 to 95%, and the inner wall surface area of the gas activation means is set to 2.1E-2m 2 , the substrate uses Ir (111) orientation film. When the oxygen flow ratio is 1%, the leakage current density is 1E-1, and as the oxygen flow ratio increases, the leakage current density decreases slowly.

[0093] However, if Figure 7 As shown, in the XRD measurement results of the PZT thin film, the (111) orientation strength is significantly reduced when the oxygen flow rate is 80% (b in the figure) compared with the oxygen flow rate of 5% (a in the figure). Figure 7 In the case of Pb / (Zr+Ti)=1.15. Figure 8 Indicates the dependen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com