Method for reclaiming oxidation catalyst

A technology of oxidation catalyst and recovery method, which is applied in the direction of chemical recovery, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., which can solve the problem of inability to improve the recovery rate of oxidation catalyst, granulation slurry solid-liquid Reduce the loss of oxidation catalyst, reduce the environmental load, and reduce the content of the problem of deteriorating separability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

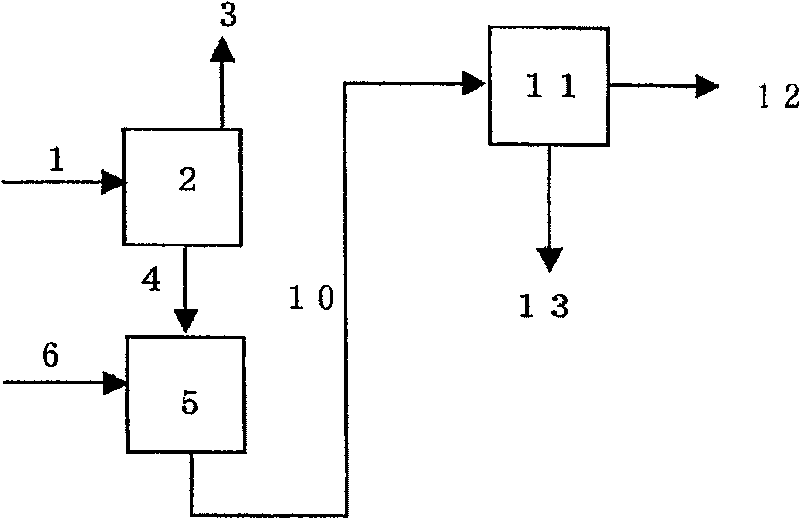

[0056] use figure 2 The symbols of are used to describe the steps of Example 1.

[0057] Manganese acetate tetrahydrate (manufactured by Wako Pure Chemical Industries, Ltd., purity 99%) containing 700 ppm in terms of cobalt atoms of cobalt acetate tetrahydrate (manufactured by Osaki Kogyo Co., Ltd., with a purity of 98% or more), and 300 ppm in terms of manganese atoms, 90% acetic acid aqueous solution of 1200ppm hydrobromic acid aqueous solution (manufactured by Tosoh Co., Ltd., hydrogen bromide concentration of 47% to 49%) in terms of bromine atoms, the mass ratio of solvent / p-xylene is taken as 5.0, The reaction temperature is 190°C, the reaction pressure is 1.1MPa, and the residence time is 60 minutes. P-xylene is oxidized by air in a continuous tank reactor, and the obtained terephthalic acid slurry is subjected to vertical centrifugation. The separator (rotation number 4500rpm) was used for solid-liquid separation to obtain oxidation reaction mother liquor and terephth...

Embodiment 2

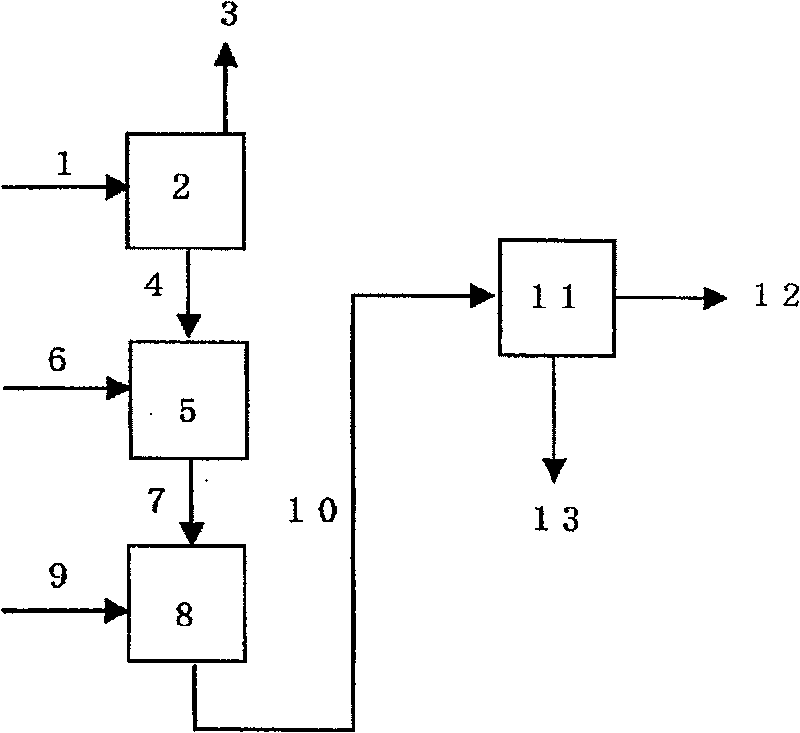

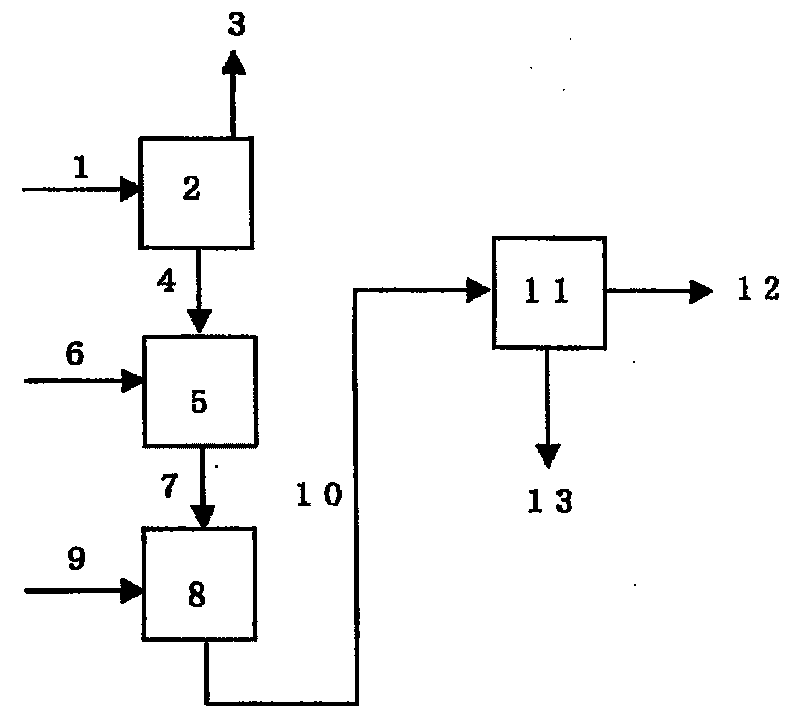

[0065] In the stirring tank (5) equipped with a jacket for heating, continuously feed the concentrate (4) prepared in the same way as in Example 1 at 400 parts by mass per hour, and continuously feed water at 200 parts by mass per hour (6), at 74 DEG C, carry out 40 minutes hot water treatment with 500rpm. In stirring tank (8), feed the hot water slurry (7) that forms with 600 mass parts per hour continuously, with 1800 mass parts per hour Parts of water (9) were continuously supplied, and granulation treatment was carried out at 700 rpm for 20 minutes at 40°C. The post-treatment of the granulated slurry was carried out in the same manner as in Example 1. As a result, the average of the obtained granulated slurry (10) Particle diameter is 1.40~2.00mm, and the water concentration of solid residue (13) after separation is 15%. Find the catalyst recovery rate of catalyst aqueous solution (12), cobalt and manganese are 93%, and bromine is 75%. The result is shown in the table 1. ...

Embodiment 3

[0067] Except having changed the hot water treatment temperature in Example 2 into 88 degreeC from 74 degreeC, it processed by the method similar to Example 2, and obtained the granulated slurry (10). The obtained granulated slurry (10) has an average particle diameter of 1.40-2.00mm, and the water concentration of the separated solid residue (13) is 15%. The catalyst recovery rate of the aqueous catalyst solution (12) was found to be 94% for cobalt and manganese, and 85% for bromine. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com