Fibrous nanometer catalyst material excited with natural light and its prepn process

A nano-catalyst and natural light technology, which is applied in the field of environmental purification materials, can solve the problem that high polymer materials cannot be used, and achieve the effects of easy separation and recovery, mild reaction conditions and high activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

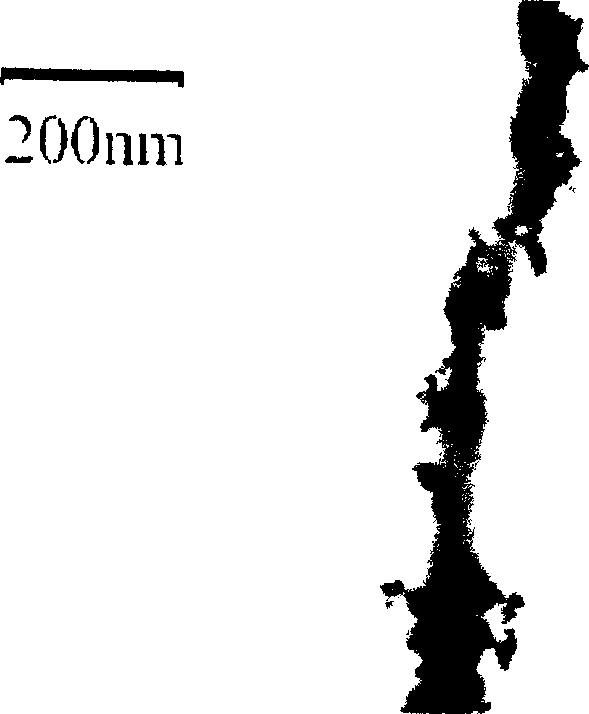

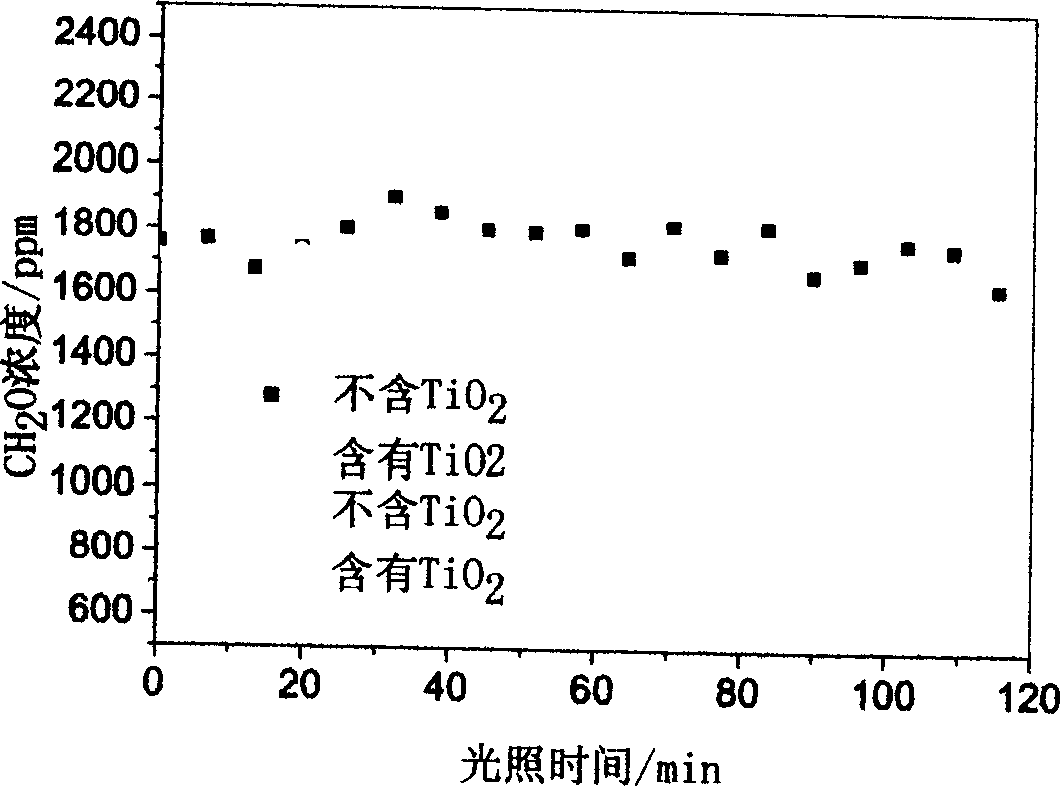

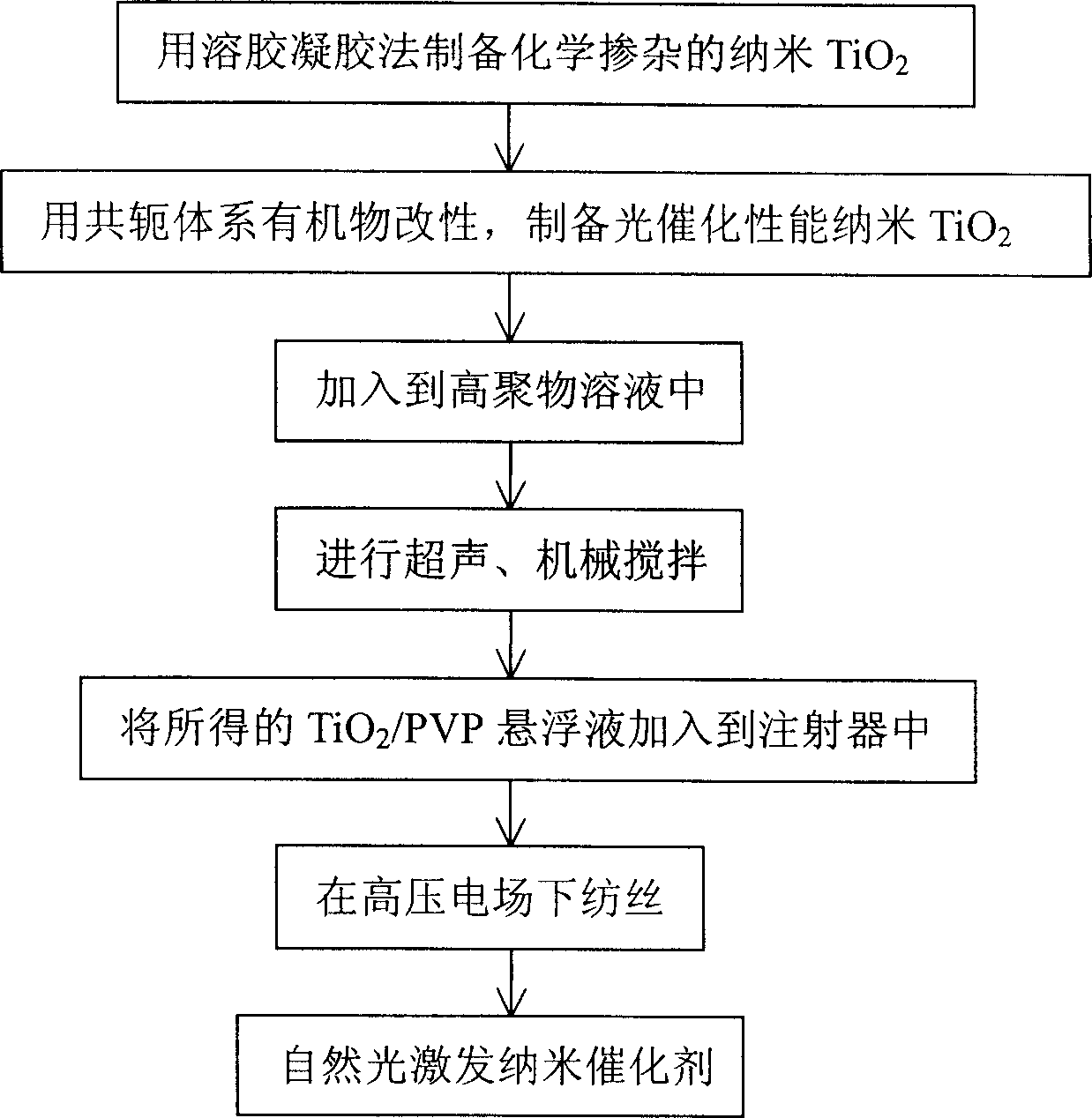

[0009] refer to figure 1 , showing the TEM image of the fibrous nanocatalyst material excited by natural light, refer to figure 2 , is the curve graph of the above materials degrading formaldehyde under visible light. refer to image 3 , has shown the process flow chart of manufacturing above-mentioned material, provides specific embodiment as follows in conjunction with this figure:

Embodiment

[0011] Step 1: Nano TiO 2 Preparation and modification Dissolve 19 g (0.15 mol) of zinc nitrate in 1000 ml of 5% NH4OH aqueous solution at room temperature. Then, using a frozen water bath, slowly drop 0.6 mol of industrial grade titanium tetrachloride into the solution, and uniformly produce a white precipitate under constant stirring. Then, 0.15 mol hydrochloric acid was added under stirring to dissolve the white precipitate and obtain a transparent liquid. The liquid was heated at 95° C. to evaporate for 2 h to remove excess water to obtain a sol-gel. The resulting sol-gel was filtered and washed 4 times with 500 ml of water to bring its pH to 7. The washed sol-gel was dried at 20° C. and 10 mmHg for 3 h to obtain a white micropowder, which is a metastable titanium dioxide precursor. Calcinate the white powder in a muffle furnace at 860°C for 1 hour to obtain a zinc oxide-doped nano-TiO2 matrix, grind the matrix, disperse it into 200ml of pure water at 50°C, and add 0.2g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com