Pollution-free production method for processing saponin from dioscorea zingibernensis

A production method and non-pollution technology, applied in the field of non-pollution production of turmeric processed saponin, can solve the problems of backward production technology, water body environmental pollution, long production cycle, etc., and achieve the effect of improving comprehensive economic benefits and saving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

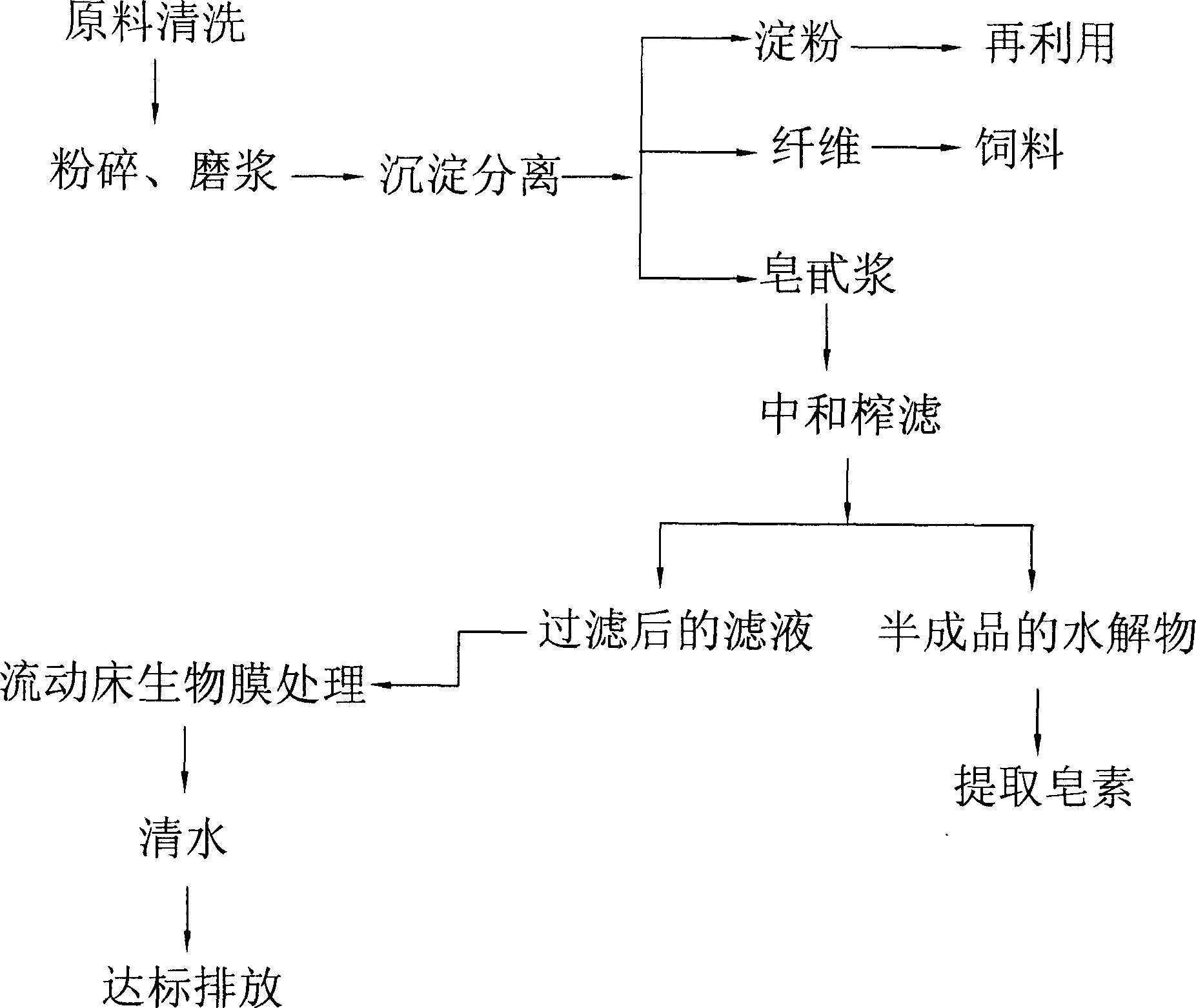

[0010] refer to figure 1 , the pollution-free production method of turmeric processed saponin of the present invention, example is as follows:

[0011] Saponin extraction process: a, raw material pretreatment: wash turmeric with clear water, crush it with a crusher, and grind it into a slurry with a colloid mill after crushing, so that the particles of the turmeric pulp reach 140-150 mesh, and the concentration is 5-12%; b, Separation of saponin pulp: firstly use a separation garden sieve or gravity sieve to separate the fibers, and then use sedimentation to separate the starch with a heavier specific gravity to obtain saponin pulp. The starch is made into finished products for recycling, and the fiber is used as feed; c. Acid hydrolysis of saponin pulp : Carry out acid hydrolysis with sulfuric acid, pressure is controlled at 0.1~0.3MPa, obtains the saponin slurry after hydrolysis; The saponin pulp is filtered by plate and frame to obtain the semi-finished hydrolyzate and fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com