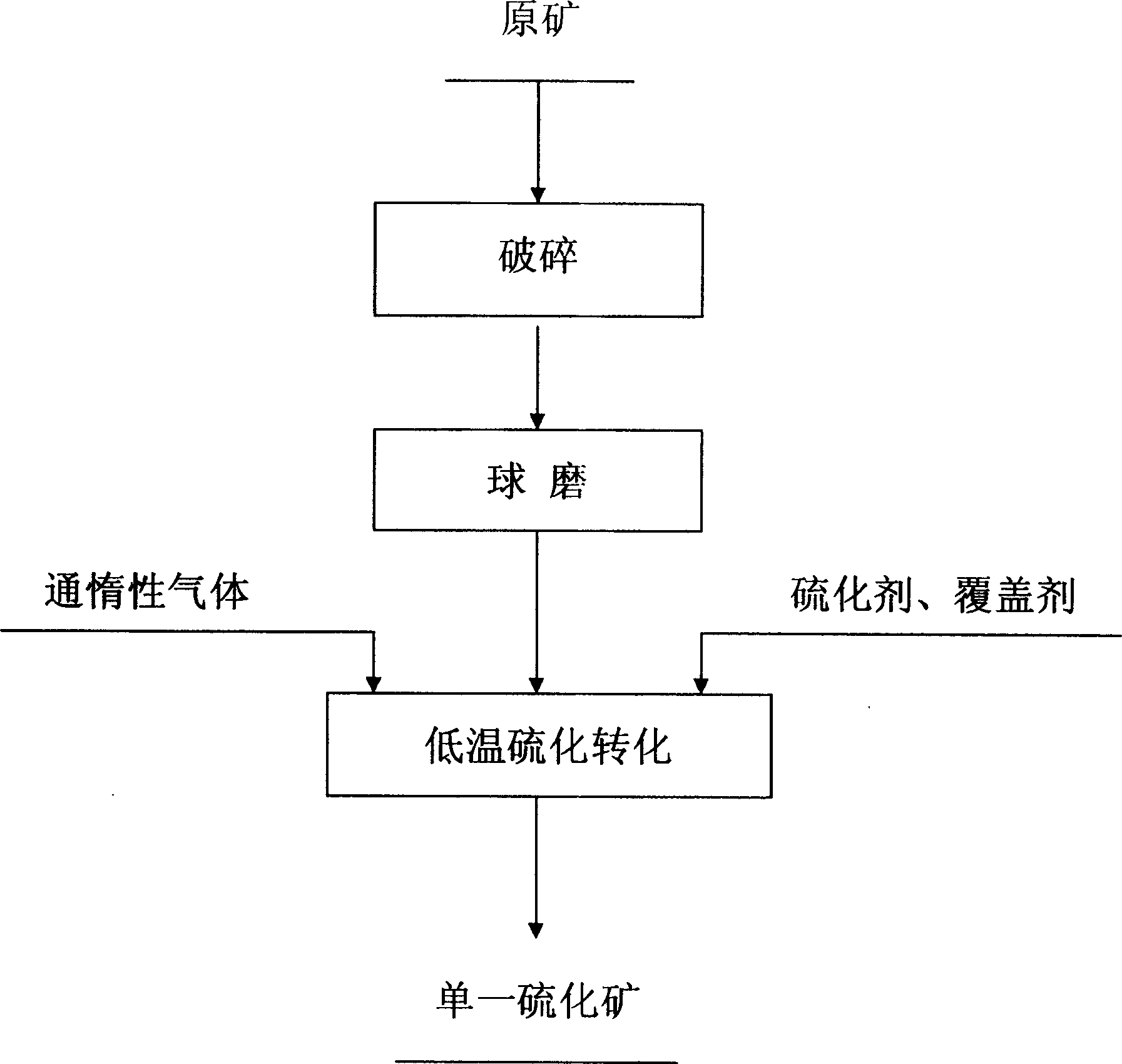

Method for converting refractory complex lead-zinc oxide ore by low-temporature sul furization

A lead-zinc oxide and low-temperature vulcanization technology, applied in the field of beneficiation and metallurgy, can solve the problems of difficulty in overcoming the complexity of minerals, low metal recovery rate, large consumption of chemicals, etc., and achieves reduced flotation process flow, simple operation, and metal recovery. The effect of rate guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Example 1: Conditions at a temperature of 100°C and an inert gas pressure of 0.01MPa:

[0017] Containing 1% lead, zinc-containing 8% refractory complex lead-zinc oxide ore and sulfur, the addition of sulfur is 0.5% of the refractory complex lead-zinc oxide ore amount mixed with graphite powder in terms of elemental sulfur, and then mixed with graphite powder. The device is continuously fed into the heating furnace, the temperature in the furnace is controlled at 100 ° C ± 1, argon is introduced to maintain the pressure of the inert gas in the furnace at 0.01 MPa, and the heating conversion of lead-zinc oxide is carried out, and the conversion time is 10 minutes.

[0018] The zinc conversion rate is 45%, the lead conversion rate is 58%, and the iron conversion rate is 60%.

Embodiment 2

[0019] Example 2: Conditions at a temperature of 900°C and an inert gas pressure of 0.1MPa:

[0020] Containing 15% of lead, containing 20% of zinc refractory complex lead-zinc oxide and iron sulfide, the addition of iron sulfide is 5.5% of the refractory complex lead-zinc oxide ore amount mixed with coke powder in terms of elemental sulfur, Use a feeder to continuously feed into the heating furnace, control the temperature in the furnace at 900 ° C ± 1, pass in argon, maintain the pressure of the inert gas in the furnace at 0.1 MPa, and carry out the thermal conversion of lead-zinc oxide. The conversion time is 180 minutes.

[0021] The zinc conversion rate is 96%, the lead conversion rate is 97.5%, and the iron conversion rate is 98.5%.

Embodiment 3

[0022] Example three: at a temperature of 650°C and an inert gas pressure of 0.08MPa:

[0023] Containing 15% lead, zinc-containing 10% refractory complex lead-zinc oxide ore and sodium sulfide, the addition of sodium sulfide is 3.5% of the refractory complex lead-zinc oxide ore amount in terms of elemental sulfur by weight and after mixing with coke, use The feeder is continuously fed into the heating furnace, the temperature in the furnace is controlled at 650 ° C ± 1, nitrogen gas is introduced to maintain the pressure of the inert gas in the furnace at 0.08 MPa, and the heating conversion of lead-zinc oxide is carried out, and the conversion time is 100 minutes.

[0024] The zinc conversion rate is 90.5%, the lead conversion rate is 93.6%, and the iron conversion rate is 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com