Halogen-free reaction extruded expansible flame-proof polythene comprising organic metal complex and its preparation method

A reactive extrusion and organometallic technology, which is applied in the field of halogen-free polyethylene and its preparation, can solve the problems of unsuitability for industrial production, low flame retardant efficiency, and environmental pollution, and achieve easy large-scale industrial production and increase oxygen index resistance. Combustibility, good charcoal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、8、9、13

[0025] (1) Preparation of reaction extruded flame retardant masterbatch First mix dipentaerythritol and melamine phosphate in a molar ratio of 1:2, and then add 20% of the total weight of the flame retardant masterbatch. Ethylene is mixed as a carrier resin, and the mixture is put into a twin-screw extruder, extruded at a speed of 40 rpm and a temperature of 160-190°C, pelletized, and dried;

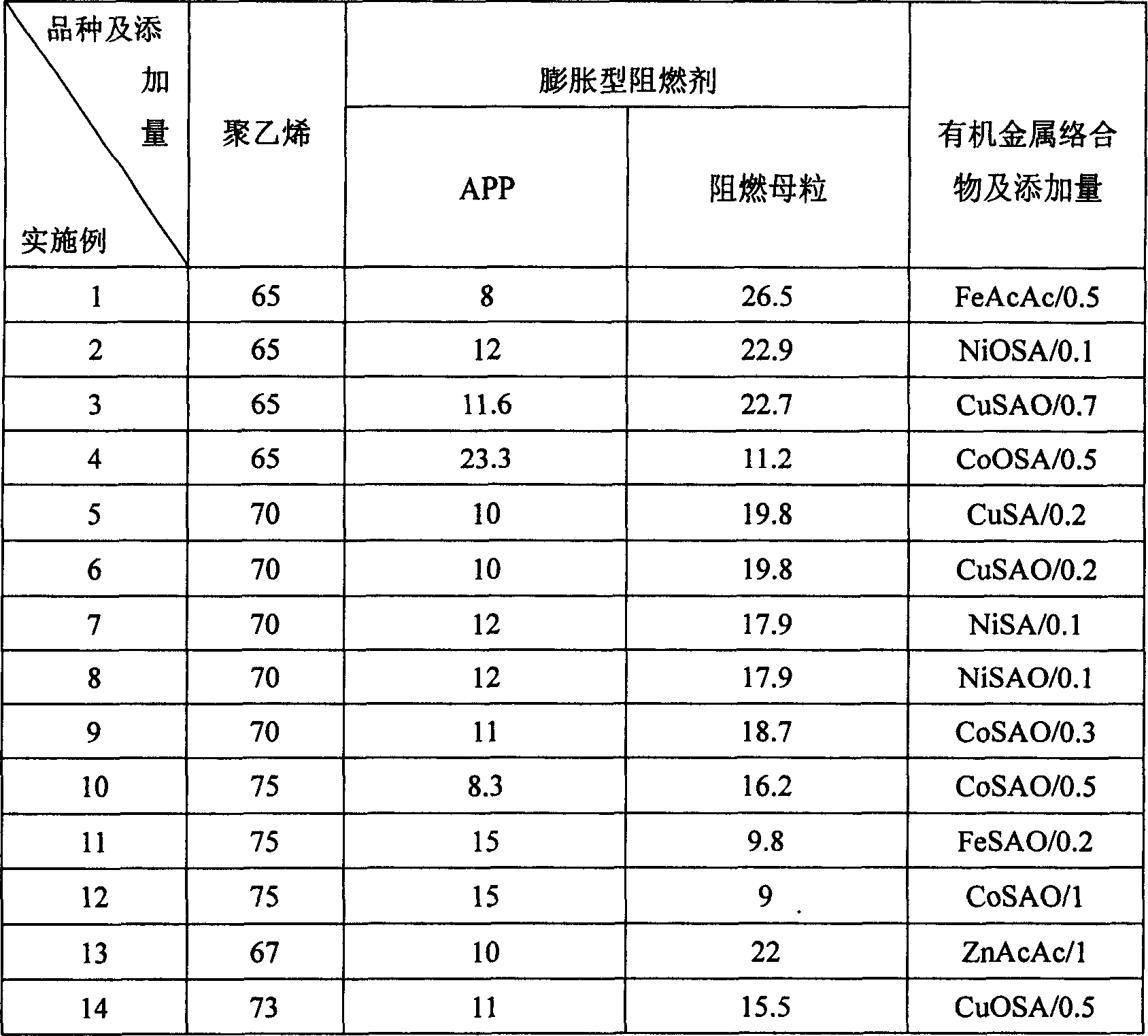

[0026] (2) The compounding ratio of reactive extrusion flame retardant masterbatch and ammonium polyphosphate after compounding and mixing, as well as the type and proportion of organometallic complexes mixed in the high-speed mixer and the amount of polyethylene added are shown in Table 1;

[0027] (3) Drying: Dry the uniformly mixed mixture at a temperature of 70°C for 9 hours;

[0028] (4) Melt mixing Put the dried mixture into a twin-screw extruder, and control the temperature in each zone of the extruder to 150°C, 160°C, 170°C, 170°C, 160°C, and 150°C for melt blending Extrusion, ...

Embodiment 2、5~7

[0031] (1) Preparation of reaction extruded flame retardant masterbatch First mix pentaerythritol and melamine phosphate in a molar ratio of 1:1.2, and then add 20% low density polyethylene based on the total weight of the flame retardant masterbatch Mix as a carrier resin, put the mixture into a twin-screw extruder, extrude, pelletize, and dry at a speed of 50 rpm and a temperature of 260-290°C;

[0032] (2) Compounding and mixing The dried reactive extrusion type flame retardant masterbatch and ammonium polyphosphate are compounded in the proportions listed in Table 1 respectively in terms of weight percentage content in expanded flame retardant polyethylene, and compounded with Table 1 The organometallic complexes of the listed varieties and proportions and polyethylene are mixed uniformly in a high-speed mixer;

[0033] (3) Drying: Dry the uniformly mixed mixture at a temperature of 80°C for 8 hours;

[0034] (4) Melt mixing Put the dried mixture into a twin-screw extrude...

Embodiment 3、10、12

[0037] (1) Preparation of reaction extruded flame retardant masterbatch First mix dipentaerythritol and melamine in a molar ratio of 1:1, and then add 20% low density polyethylene based on the total weight of the flame retardant masterbatch as The carrier resin is mixed, and the mixture is put into a twin-screw extruder, extruded at a speed of 10 rpm and a temperature of 270-300°C, pelletized, and dried;

[0038] (2) The compounding ratio of reactive extrusion flame retardant masterbatch and ammonium polyphosphate after compounding and mixing, as well as the type and proportion of organometallic complexes mixed in the high-speed mixer and the amount of polyethylene added are shown in Table 1;

[0039] (3) Vacuum drying Dry the uniformly mixed mixture at a temperature of 90°C for 10 hours;

[0040] The following melt mixing and cooling pelletizing steps are controlled as 50 rev / min except that the screw speed is controlled, all the other are the same as in Example 1, omitted. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com