Agarose aquogel fixed enzyme electrode and its preparation method and application

A technology of agarose hydrogel and immobilized enzymes, which is applied in the direction of material analysis, measuring devices, and instruments through electromagnetic means, which can solve the problems of unusable enzyme electrodes, poor biological affinity, and large mass transfer resistance, and achieve swelling Small effect, good biocompatibility, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

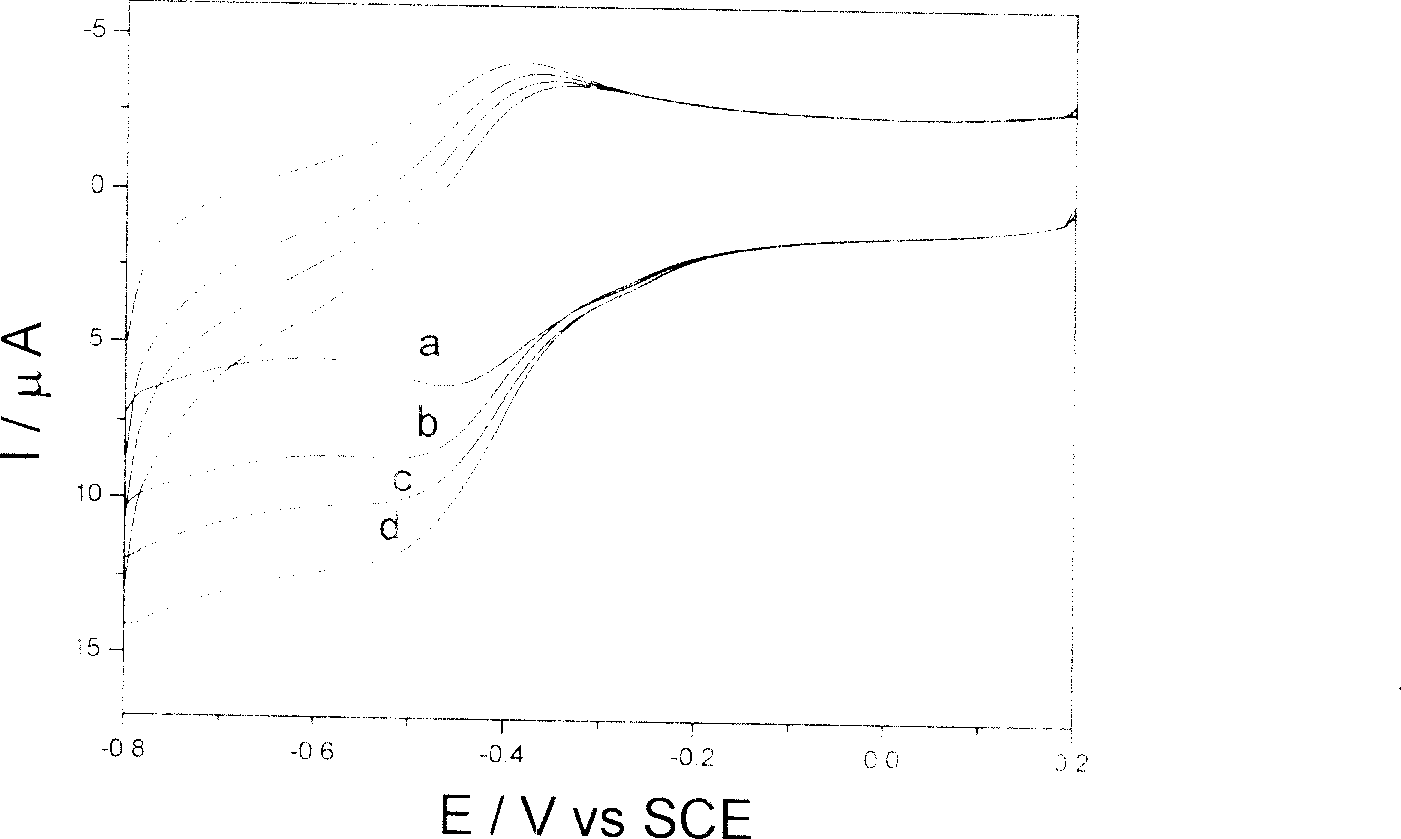

Embodiment 1

[0021] Preparation of hemoglobin-modified electrodes. Agarose (0.4g, agarose, Sigma) was dissolved in 100mL of boiling water, then cooled at room temperature to prepare a 0.4% hydrogel, and the mixed solution of agarose hydrogel and N, N-dimethylformamide (DMF) (agarose:DMF=4:1), and hemoglobin solution (1.34×10 -4 M) Equal volumes are mixed. Take 10 μl of the mixed solution and drop-coat it on the surface of the cracked graphite electrode, cover the small tube with holes, and dry it at room temperature for about 8 hours. The electrode has excellent performance, fast response time (30 seconds); long service life (30 days); high accuracy (<5%); good precision (<5‰) in aqueous phase, aqueous organic phase and organic phase Among them, it can detect nitric oxide, peroxide and ethyl chloride with a wide measurement range.

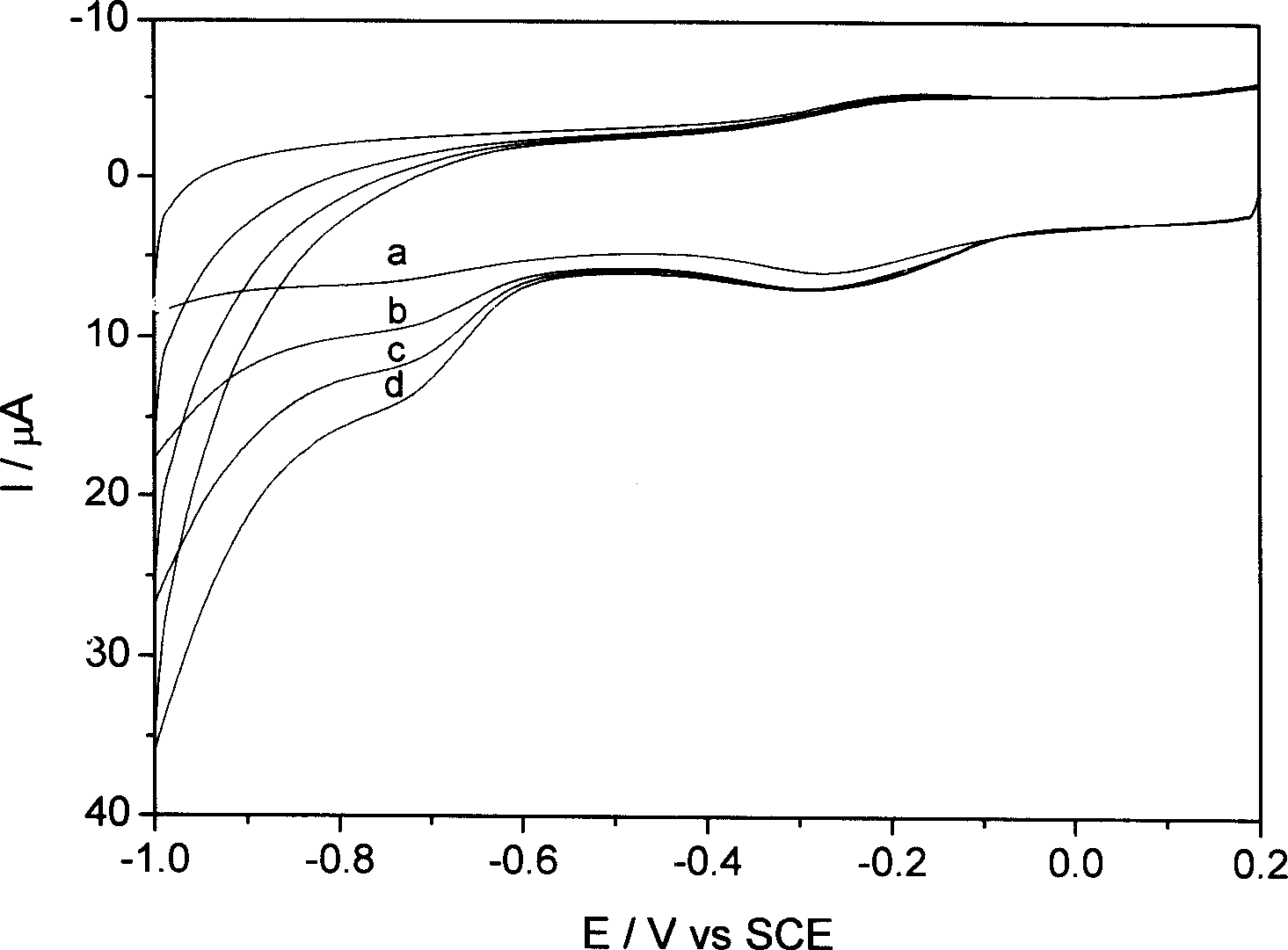

Embodiment 2

[0023] Prepare a myoglobin-modified electrode. Agarose (0.4g, agarose, Sigma) was dissolved in 100mL of boiling water, then cooled at room temperature to prepare a 0.4% hydrogel, and the mixed solution of agarose hydrogel and N, N-dimethylformamide (DMF) (agarose:DMF=4:1), and myoglobin solution (2.04×10 -5 M) Equal volumes are mixed. Take 10 μl of the mixed solution and drop-coat it on the surface of the cracked graphite electrode, cover the small tube with holes, and dry it at room temperature for about 8 hours. The electrode has excellent performance, fast response time (30 seconds); long service life (30 days); high accuracy (<5%); good precision (<5‰) in aqueous phase, aqueous organic phase and organic phase Among them, it can detect nitric oxide, peroxide and ethyl chloride with a wide measurement range.

Embodiment 3

[0025] Preparation of horseradish peroxidase modified electrode. Agarose (0.4g, agarose, Sigma) was dissolved in 100mL of boiling water, then cooled at room temperature to prepare a 0.4% hydrogel, and the mixed solution of agarose hydrogel and N, N-dimethylformamide (DMF) (agarose:DMF=4:1), and horseradish peroxidase solution (7.82×10 -5 M) Equal volumes are mixed. Take 10 μl of the mixed solution and drop-coat it on the surface of the cracked graphite electrode, cover the small tube with holes, and dry it at room temperature for about 8 hours. The electrode has excellent performance, fast response time (30 seconds); long service life (30 days); high accuracy (<5%); good precision (<5‰) in aqueous phase, aqueous organic phase and organic phase Among them, it can detect peroxide and has a wide measurement range.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com