Method of sterilization and electrolytic water ejecting apparatus

A technology of electrolyzing water and equipment, applied in water/sewage treatment equipment, electrolytic components, electrolysis process, etc., can solve problems such as size reduction, electrode activity reduction, and difficulty in instant preparation, etc., and achieve excellent instant response characteristics, Improvement of electrode durability and improvement of sterilizing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

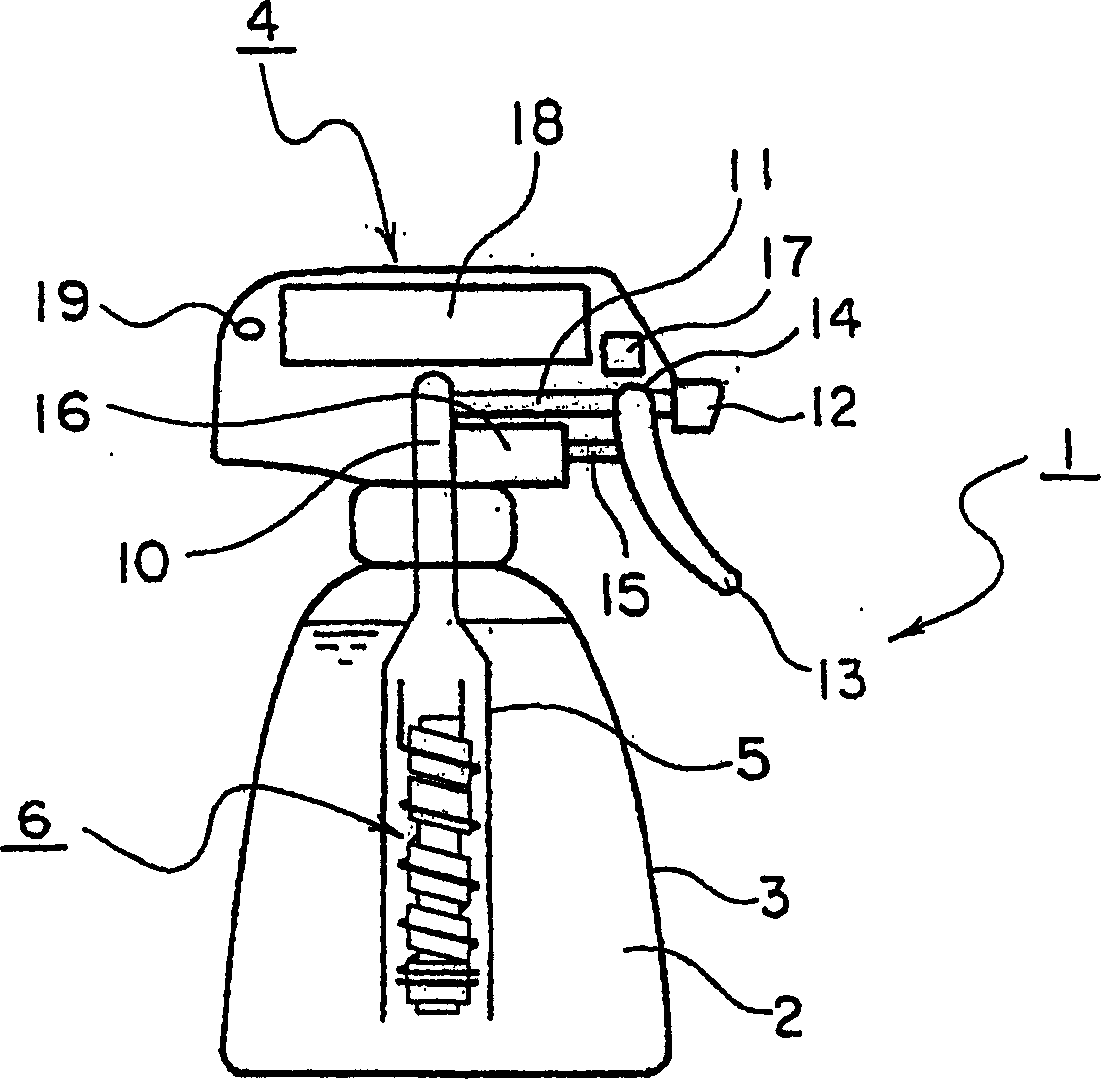

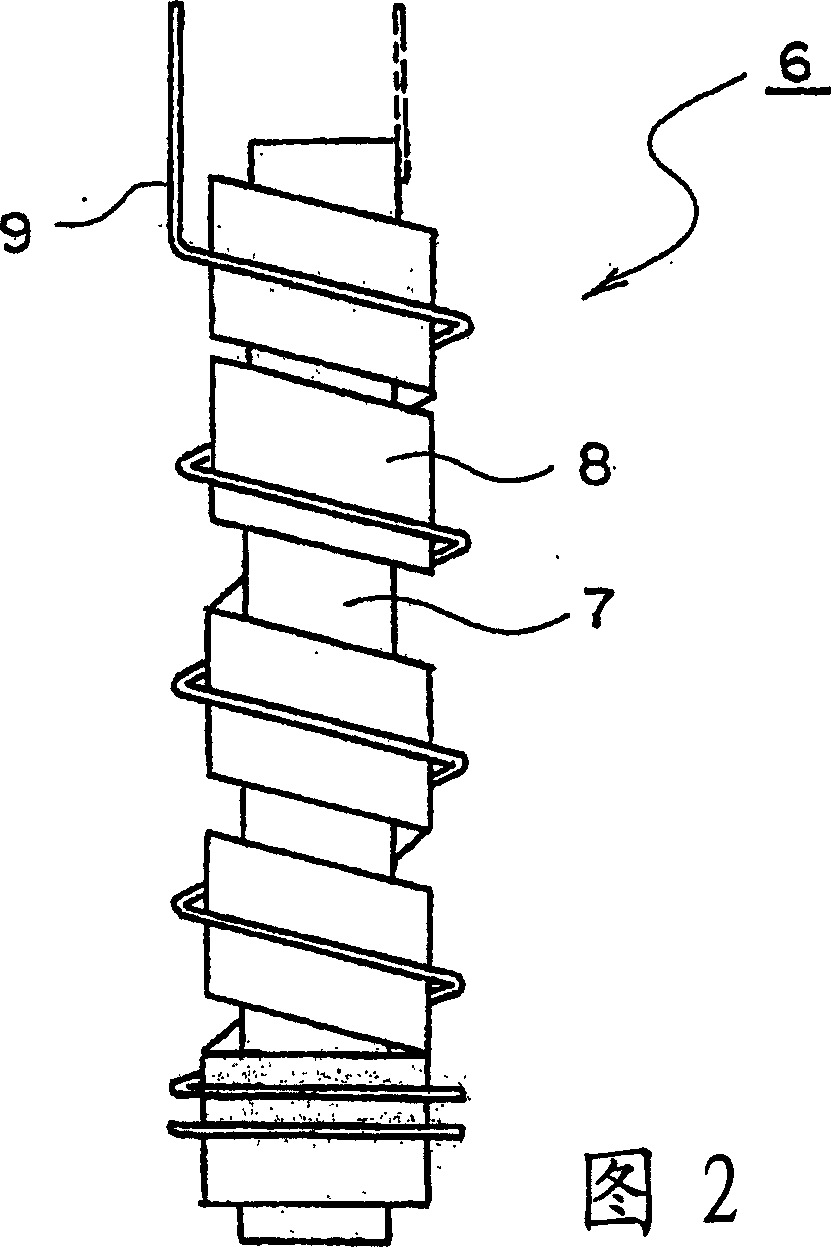

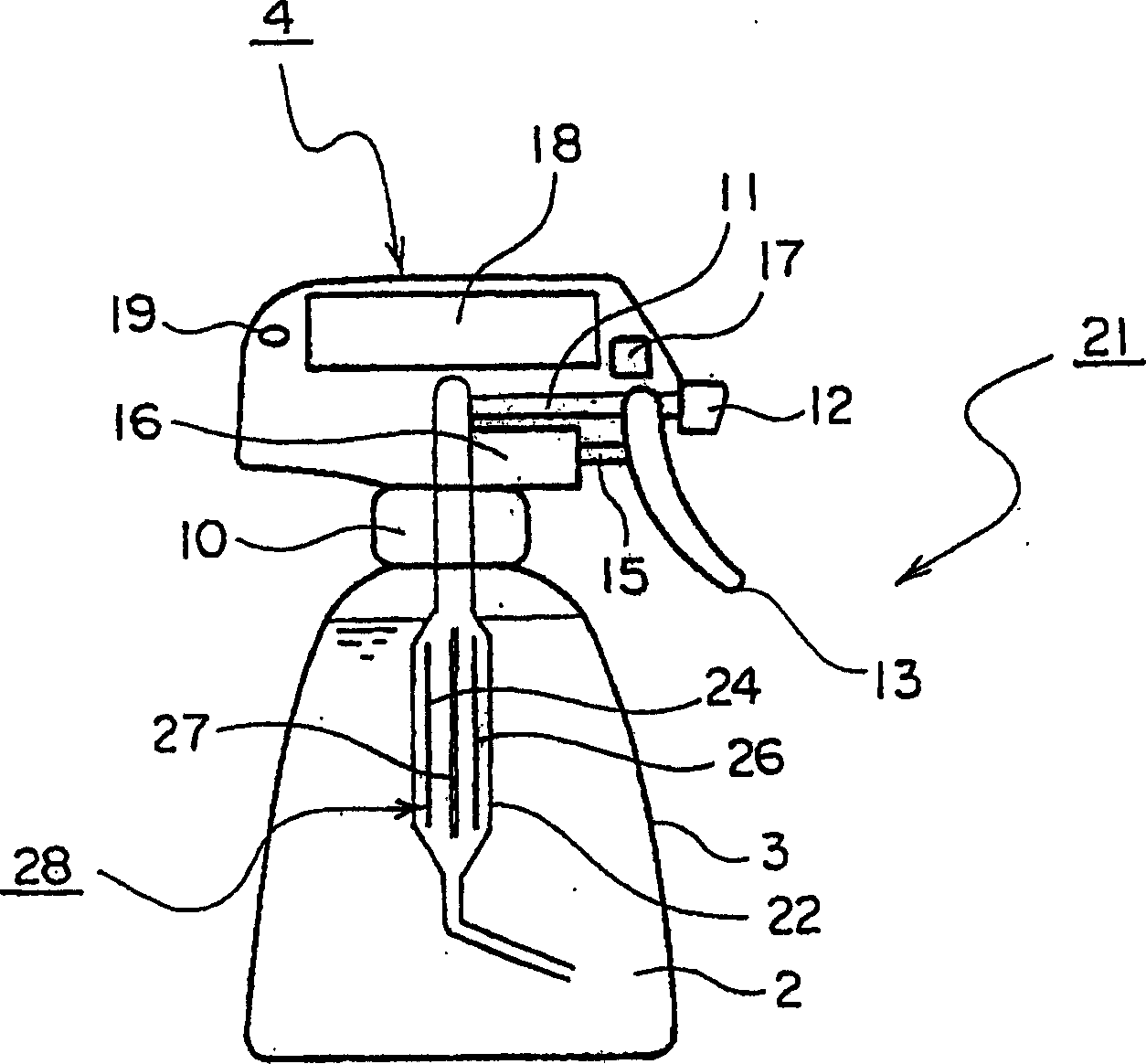

[0177] A niobium rod (diameter 2 mm; length 10 cm) on which conductive diamond was deposited (diamond thickness 3 μm; dopant boron concentration 500 ppm) was used as an anode. An ion exchange membrane tape (Nafion 350, produced by DuPont; 0.4 mm in thickness and 1 mm in width) was wound on the anode as a separator. A commercially available platinum wire (0.5 mm in diameter) was wound on the separator as a cathode, thereby integrating the anode, the membrane, and the cathode. This assembly (electrolytic unit; effective electrode area is 6cm 2 ) fixed at figure 1 and the inside of the PE resin delivery pipe in the trigger type spraying equipment shown in Fig. 2.

[0178] A 9V square battery is installed in the sprinkler head of the trigger type sprinkler. In the circuit section, electrode terminals are connected to variable resistors and switches with wiring. Add 500cc of pure water to the container. Pull the trigger and the circuit will close, allowing current to flow betw...

Embodiment 2

[0182] The same test as in Example 1 was performed except that pure water containing 0.1 g / L acetic acid was added to the container. As a result, the ozone concentration in the obtained solution was 3.5 ppm. The terminal voltage of the electrolytic unit is 7V, and the current is 0.3A. Store the ozone-containing water in airtight glass containers at room temperature. As a result, the initial concentration was maintained even after 2 hours. Repeat the trigger action 2,000 times. As a result, the current efficiency in each operation was almost equal to the initial value.

Embodiment 3

[0184] The same test as in Example 1 was carried out except that tap water containing 2 g / L of sodium chloride was added to the container. As a result, the ozone concentration and the hypochlorous acid concentration in the obtained solution were 0.8 ppm and 20 ppm, respectively. The terminal voltage of the electrolytic unit is 6.5V, and the current is 0.35A. Repeat the trigger action 2,000 times. As a result, the current efficiency per operation was almost equal to the initial value, and deposition of calcium and magnesium compounds was observed on the cathode of the electrolytic cell.

PUM

| Property | Measurement | Unit |

|---|---|---|

| composition ratio | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com