Compound powder for high molecular plastic alloy thermal smelting anti-corrosion thick lining

A plastic alloy and anti-corrosion technology, applied in anti-corrosion coatings, powder coatings, polyester coatings, etc., can solve the problems of thick-film anti-corrosion linings such as air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The specific implementation of the present invention will be described in detail below in combination with specific situations.

[0008] Given by technical scheme, the present invention is by weight:

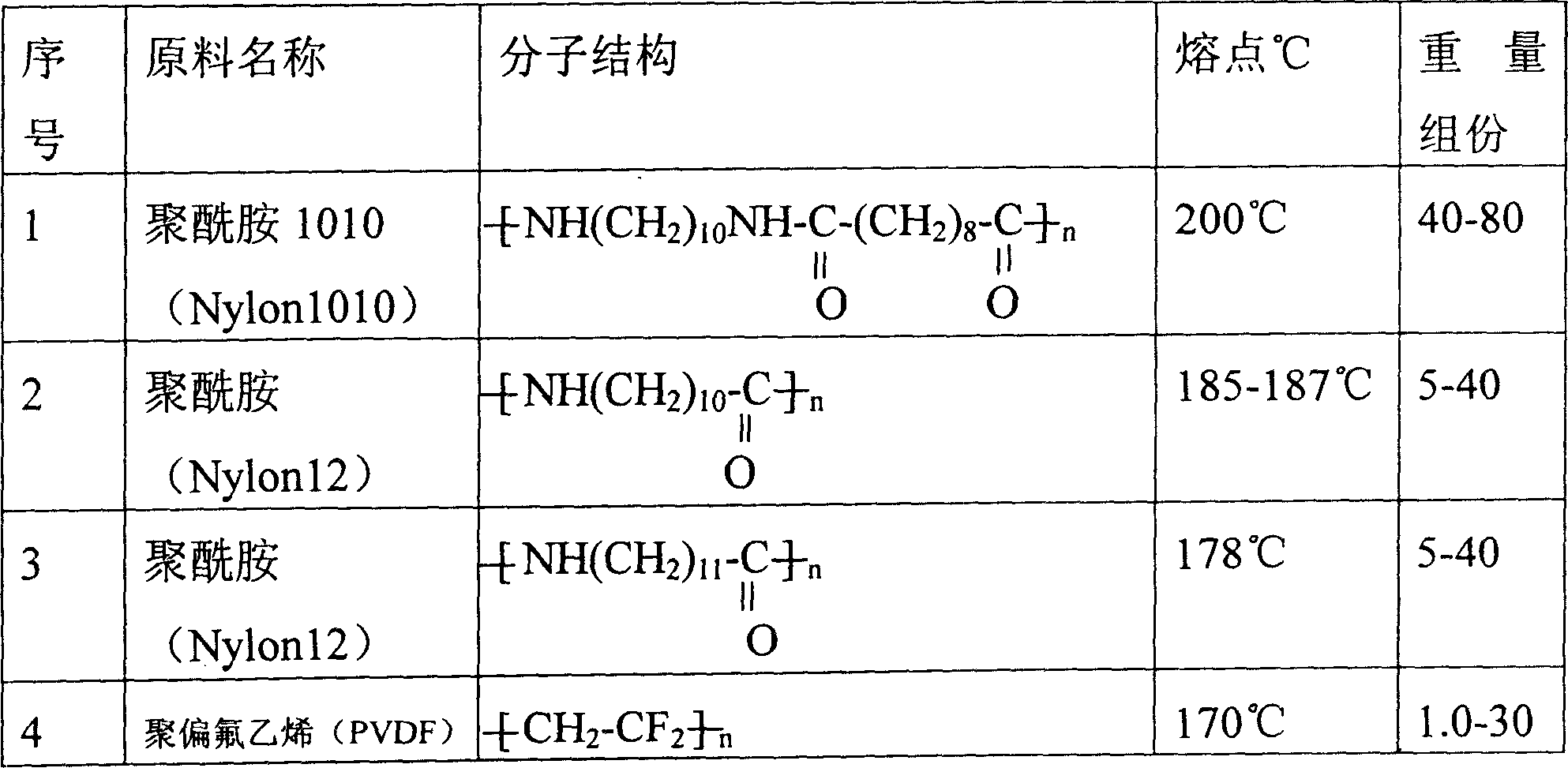

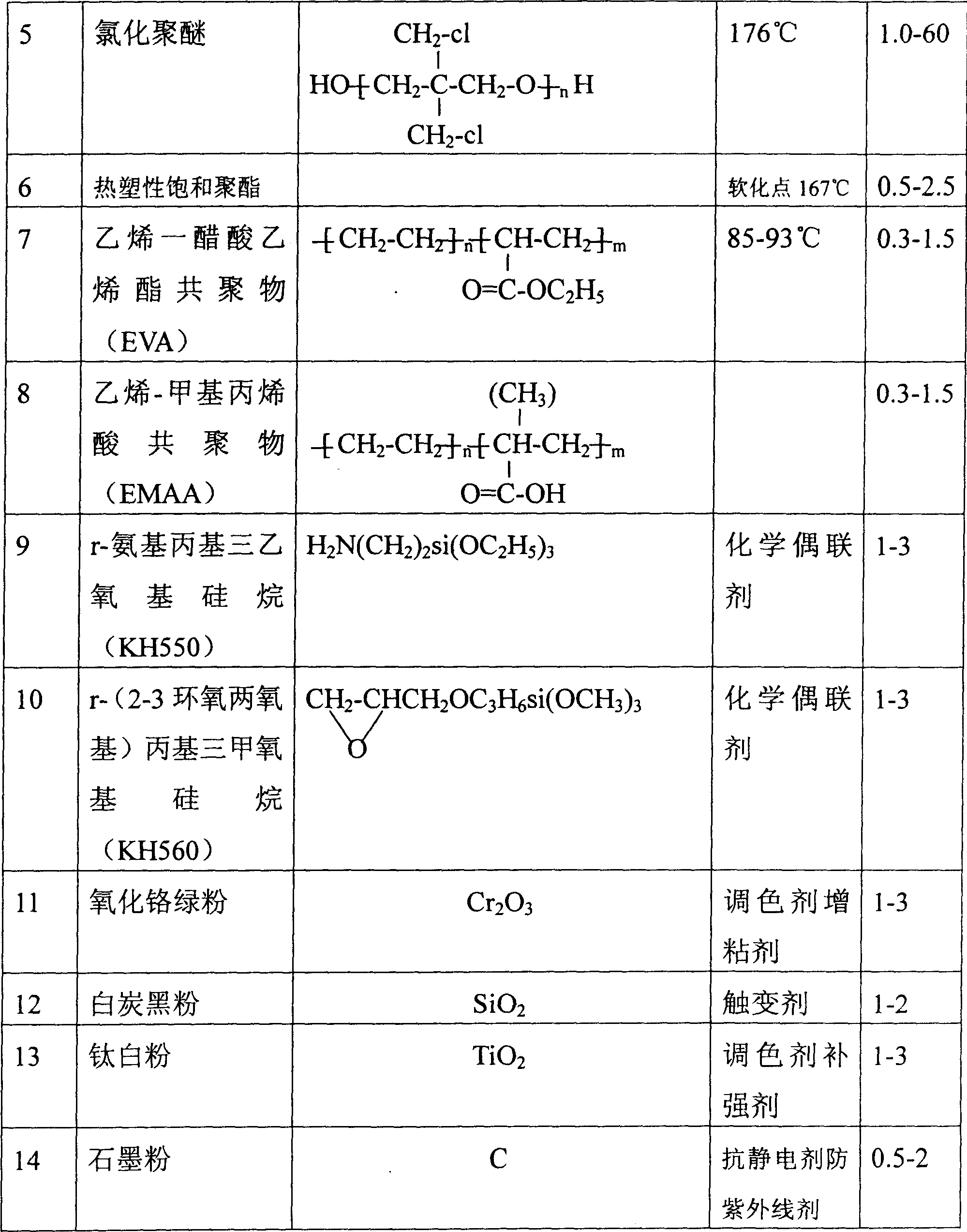

[0009] Polyamide 1010 40-80 parts, polyamide 11 (that is, nylon 11, or written as NyLon11) 5-40 parts, polyamide 12 (that is, nylon 12, or written as NyLon12) 5-40 parts, polyvinylidene fluoride 1-30 parts , 1-60 parts of chlorinated polyether (pentone), 0.5-2.5 parts of thermoplastic saturated polyester, 0.3-1.5 parts of ethylene-vinyl acetate copolymer (or called ethylene-vinyl acetate copolymer, referred to as EVA), ethylene - 0.3-1.5 parts of methacrylic acid copolymer (ie EMAA), 1-3 parts of r-aminopropyl triethoxysilane, 1-3 parts of r-(2-3 epoxydioxy) propyl trimethoxysilane 3 parts, composed of 1-3 parts of chromium oxide green powder, 1-2 parts of white carbon black powder, 1-3 parts of titanium dioxide powder and 0.5-2.0 parts of graphite powder. The details of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com