Catalyst, process for preparing the catalyst and process for producing lower hydrocarbon with the catalyst

A low-level hydrocarbon and zeolite catalyst technology, applied in the direction of molecular sieve catalysts, organic chemical methods, chemical instruments and methods, etc., can solve problems such as poisoning, short catalyst life, etc., to reduce manufacturing costs, prolong catalyst life, and small average particle size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] [Preparation of zeolite raw material solution]

[0022] Contain SiO in the zeolite raw material liquid used in the present invention 2 source, metal oxide source, alkali source and skeleton structure regulator. As SiO in the zeolite raw material liquid composition 2 As a source, water glass, silica sol, silica gel, silica, etc. are mentioned. Among them, water glass and silica sol are preferable. Moreover, these SiO 2 The sources may be used alone or in combination of two or more.

[0023] Examples of the metal oxide source in the zeolite raw material liquid component used in the present invention include water-soluble metal salts containing aluminum, titanium, gallium, and the like. Among them, trivalent metal oxides are preferable, and aluminum salts are more preferable. Specific examples include aluminum nitrate, aluminum sulfate, sodium aluminate, aluminum sol, and the like. Moreover, these metal oxide sources may be used individually, or may mix and use 2 or...

Embodiment 1

[0044]

[0045] It was produced by an improved production method based on the production example of Patent Document 1 (JP-A-63-35570).

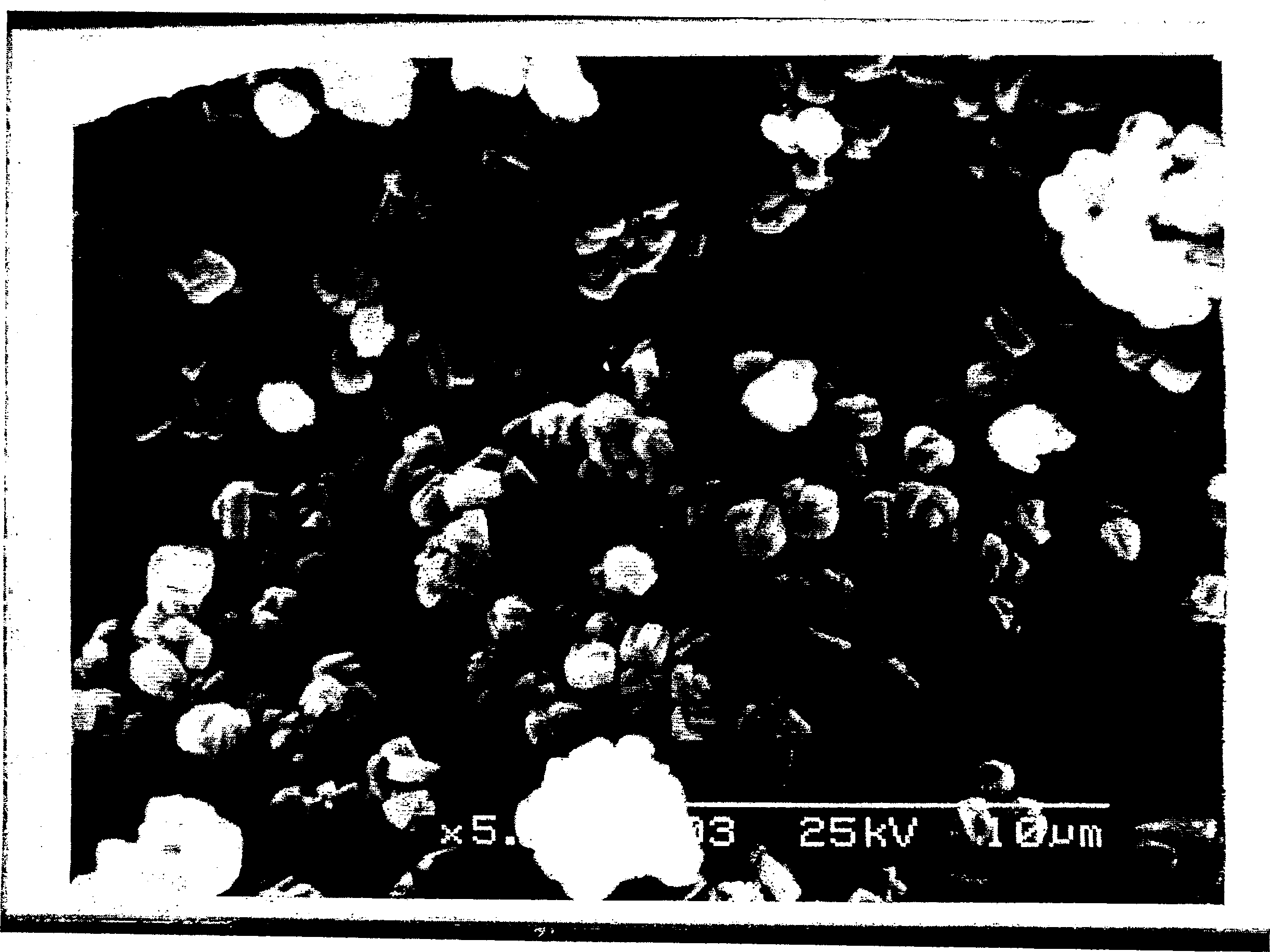

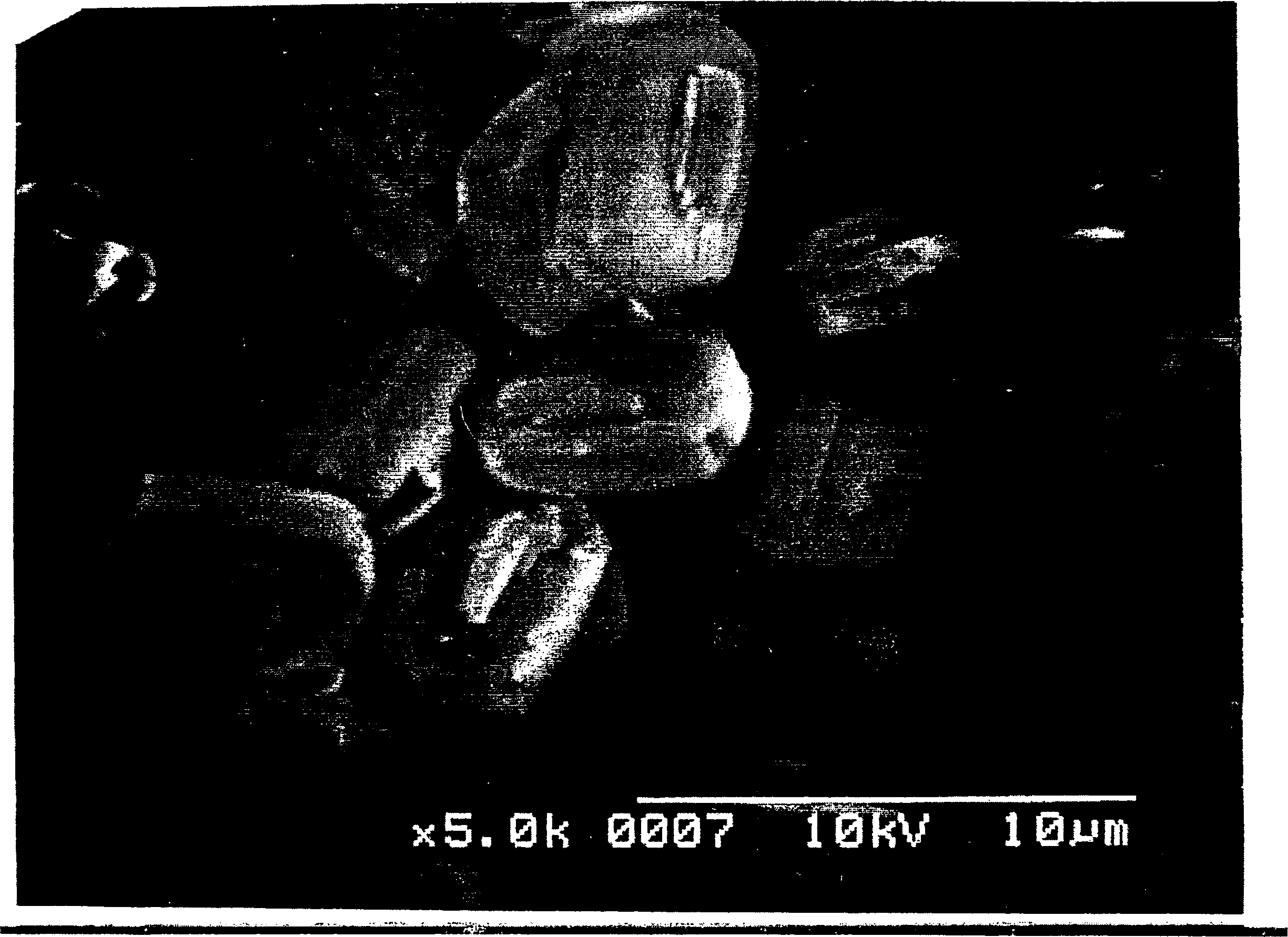

[0046] will contain 9.50g of Al(NO 3 ) 3 9H 2 O, 10.92g of Ca(CH 3 COO) 2 ·H 2 The zeolite raw material solution of O was dissolved in 750 g of water, and the following were added thereto while stirring: a solution in which 500 g of Cataroid Si-30 water glass (manufactured by Catalyst Chemical Industry) was dissolved in 333 g of water, 177.5 g of 6 mass % NaOH aqueous solution, and 21.3 mass % tetrapropylammonium bromide aqueous solution 317.6g, 15.0g (equivalent to 15.0g of ammonium type MFI structure zeolite (manufactured by Zeolyst Co., Si / Al atomic ratio: 70) with an average particle size of 0.5 μm as zeolite seed crystals (equivalent to 10% by mass of the synthetic zeolite catalyst mass) to obtain an aqueous gel mixture.

[0047] Next, this aqueous gel mixture was placed in a 3 L autoclave container, and stirred at 160° C. for 18...

Embodiment 2

[0059] Except that the addition amount of the zeolite seed crystal becomes 75g (corresponding to 50% by mass of the zeolite catalyst mass synthesized without adding the seed crystal), the same as in Example 1, a proton-type zeolite with an alkaline earth metal-containing MFI structure was produced. catalyst. The physical property values and performance of the catalyst were evaluated in the same manner as in Example 1. Table 1 shows the physical property values and catalytic performance of the catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com